Light conversion film with long service life and preparation method thereof

A light-converting film and long-life technology, which is applied in botany equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of accelerating the aging of agricultural film, affecting the life of agricultural film, and fast strength decay, so as to promote plant growth , saving planting costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the light conversion film with long service life includes the following steps:

[0036] 1) Prepare plastic layer premix and isolation layer premix respectively;

[0037] 2) Fully mix the matrix resin, light converting agent, lubricant, light stabilizer and antioxidant to obtain a light converting layer premix;

[0038] 3) Adding the plastic layer premix, the isolation layer premix and the light conversion layer premix into a co-extruder for multi-layer co-extrusion to obtain a light conversion film with a multi-layer structure.

Embodiment 1

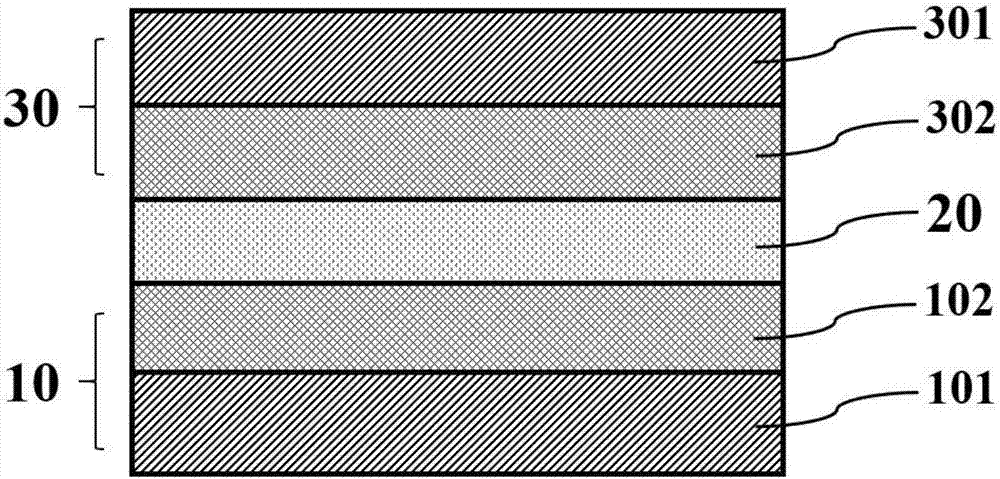

[0041] Such as figure 1 As shown, a light conversion film with long service life includes a first protective layer 10, a light conversion layer 20 and a second protective layer 30; the first protective layer 10 is composed of a plastic layer 101 and an isolation layer 102, and the material of the plastic layer 101 It is polyethylene with a thickness of 20 μm, and the material of the isolation layer 102 is nylon with a thickness of 10 μm; the light conversion layer 20 is composed of polyethylene, rare earth inorganic sulfide light conversion agent, lubricant, light stabilizer and antioxidant, and the thickness is 100 μm. 40 μm; the second protective layer 30 is composed of a plastic layer 301 and an isolation layer 302, the material of the plastic layer 301 is polyethylene, the thickness is 20 μm, the material of the isolation layer 302 is nylon, and the thickness is 10 μm; the total thickness of the light conversion film is 100 μm .

[0042] The absorption spectrum and emissi...

Embodiment 2

[0044] Such as figure 1 As shown, a light conversion film with long service life includes a first protective layer 10, a light conversion layer 20 and a second protective layer 30; the first protective layer 10 is composed of a plastic layer 101 and an isolation layer 102, and the material of the plastic layer 101 It is nylon with a thickness of 5 μm, and the material of the isolation layer 102 is ethylene / vinyl alcohol copolymer with a thickness of 5 μm; the light conversion layer 20 is made of polypropylene, rare earth inorganic sulfide light conversion agent, lubricant, light stabilizer and antioxidant The second protective layer 30 is composed of a plastic layer 301 and an isolation layer 302, the material of the plastic layer 301 is nylon, and the thickness is 5 μm, and the material of the isolation layer 302 is CTC resin, and the thickness is 5 μm; The total thickness is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com