Selective process for conversion of levulinic acid to gammavalerolactone

A technology of levulinic acid and valerolactone is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unsatisfactory, and achieve the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Levulinic acid production involves the concept of a biorefinery, a facility that integrates biomass conversion methods and equipment to produce fuels, power and chemicals from biomass.

[0020] The chemical composition of biomass strongly depends on its source. The most abundant carbohydrate in nature is cellulose. Cellulose is an unbranched, water-insoluble polysaccharide composed of several hundred to up to tens of thousands of glucose units. Levulinic acid can be produced from a hexose sugar, such as glucose, by an acid-catalyzed reaction that yields 1 mole of both levulinic acid and formic acid from 1 mole of hexose sugar. Levulinic acid can be used as such for different applications, or further reacted to generate other bioprecursors or bioproducts.

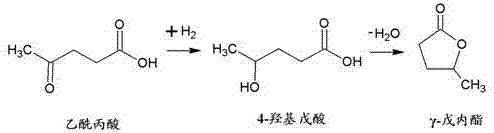

[0021] The reaction of levulinic acid to γ-valerolactone via 4-hydroxyvaleric acid was performed according to the following scheme.

[0022]

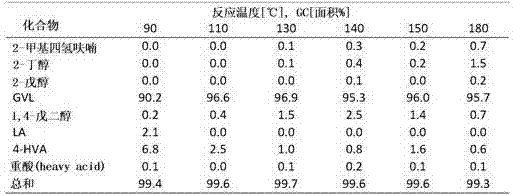

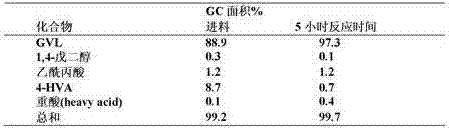

[0023] Although hydrogenation and cyclization are given as subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com