Method for coating metal surfaces with activators prior to phosphating

A metal surface and activator technology, which is applied to the surface coating liquid device, pretreatment surface, metal material coating process, etc., can solve the problems of high layer weight, high chemical consumption, and reduced paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

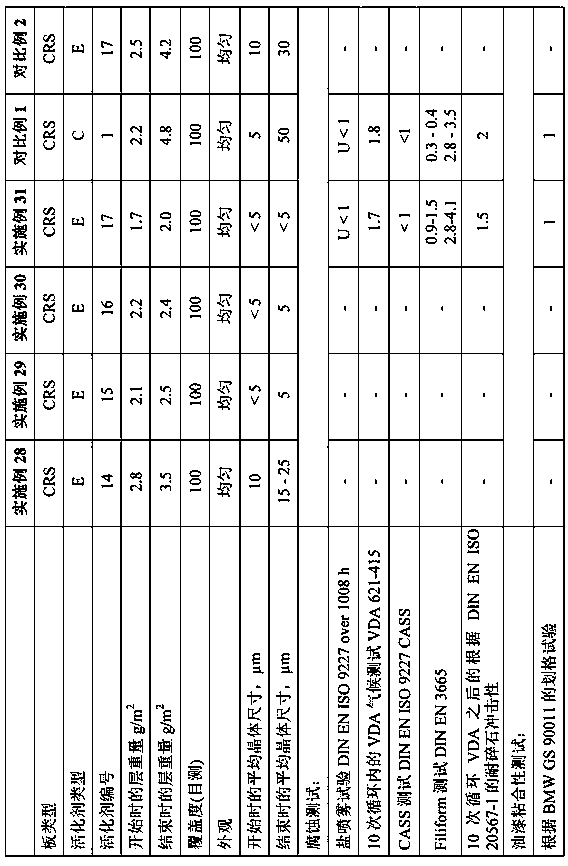

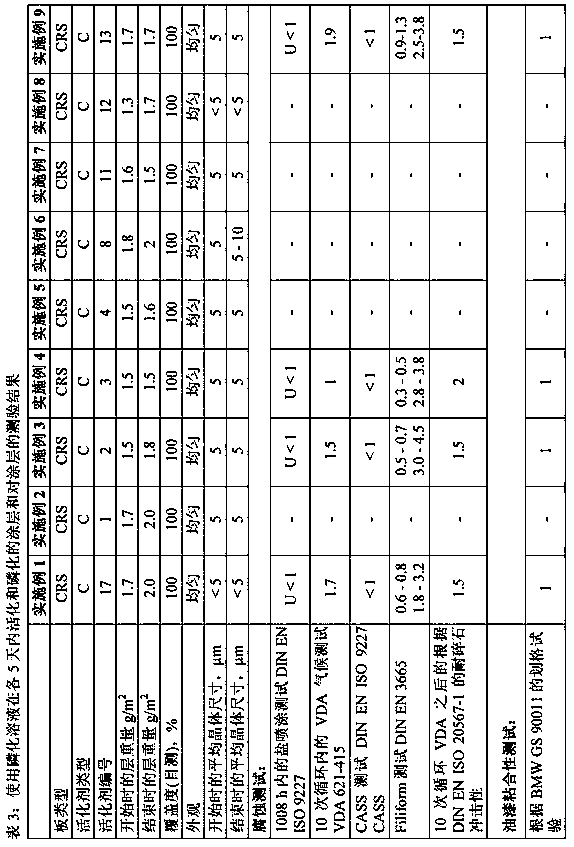

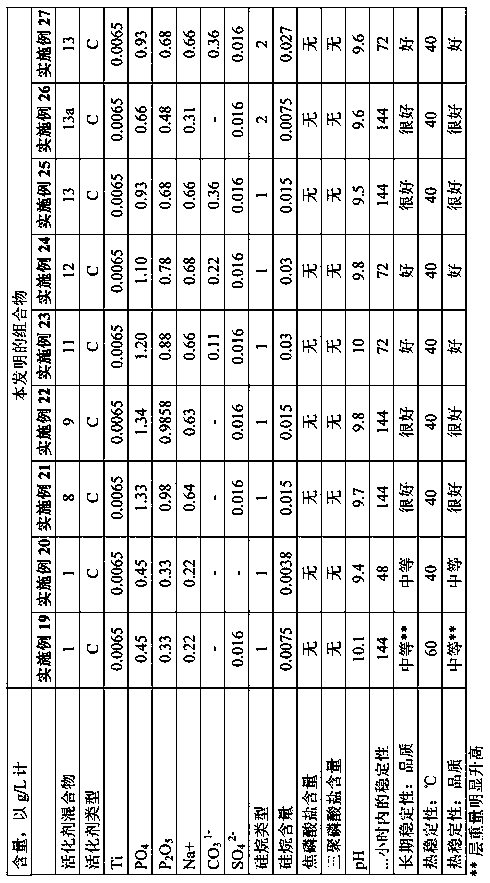

[0146] Embodiment and comparative example:

[0147] The subject matter of the invention is described in more detail by working examples. The examples were carried out using the following substrates, method steps, substances and mixtures:

[0148]The test plate consists of cold-rolled steel (CRS) or double-sided galvanized steel with a thickness of 1.2 mm and has a hot-dip galvanized (HDG) or electrogalvanized (EG) coating on each side with a thickness of about 7 μm each . The area of the substrate measured on both sides is about 400 cm 2 .

[0149] a) Clean and fully degrease the surface of the substrate in a 2.5% solution of alkaline detergent at 60°C for 10 minutes.

[0150] b) Then rinse with tap water for 0.5 minutes at room temperature.

[0151] c) The surface is then activated by immersing it in a colloidal activator comprising titanium phosphate for 0.5 minutes at room temperature. Activators are described in Table 2. Activator A is prepared by mixing at eleva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com