Anti-air impact hydraulic system and control method of rock drill

A hydraulic system and rock drilling machine technology, which is applied in the anti-air shock hydraulic system and control field of rock drilling machines, can solve the problems of increasing construction costs, having no effect on rock drilling, shortening the service life of rock drilling machines, etc., and achieving the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

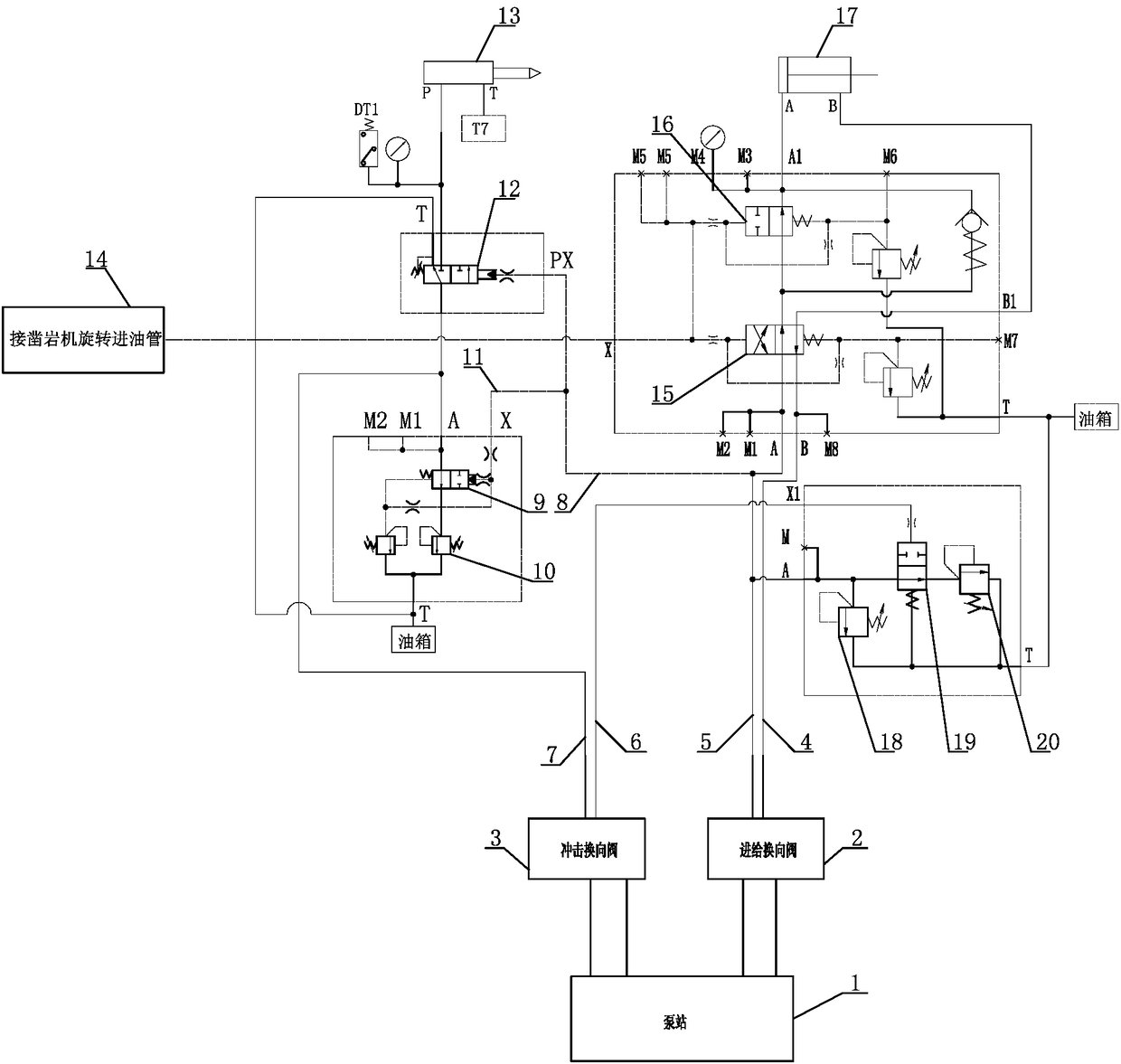

[0025] like figure 1 As shown, the anti-aircraft impact hydraulic system of a rock drill includes a hydraulic pump station 1, which is connected with a forward feed oil pipe 5 and a reverse feed oil pipe 4 through a feed reversing valve 2; the hydraulic pump station 1 is connected to the shock oil pipe 7 and the low pressure shock oil pipe 6 through the shock reversing valve 3; a first hydraulic control reversing valve 12 is installed on the oil circuit after the shock oil pipe 7, and the liquid of the first hydraulic control reversing valve 12 is installed. The control end is connected to the forward feed oil pipe 5 through the first hydraulic control oil pipe 8, and the first hydraulic control reversing valve 12 is connected to the impact oil cylinder 13; The second reversing valve 16 is connected to the feed cylinder 17 . During the working process, the feeding pressure of the feeding cylinder 17 will be fed back to the shock oil pipe 7 at the same time. By connecting the ...

Embodiment 2

[0032] A control method for the anti-aircraft impact hydraulic system of the rock drill, which comprises the following steps:

[0033] 1) Set the opening pressure of the first hydraulic control reversing valve 12 and the second hydraulic control reversing valve 9, and keep their opening pressures consistent;

[0034] 2) Open the forward feed pipe 5 and start the feed cylinder 17;

[0035] 3) When the rock drill has not been in contact with the rock formation or because of the holes and softness of the rock formation, the pressure of the forward feeding oil pipe 5 is very small. At this time, the pressure of the forward feeding oil pipe 5 is smaller than that of the first hydraulic control valve 12 When the opening pressure is increased, the first hydraulic control reversing valve 12 will not change direction, and the hydraulic oil impacting the oil pipe 7 will directly return to the oil tank through the first hydraulic control reversing valve 12, and the rock drill will not ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com