Rotary hydromechanical meshing characteristic test bench

A technology for fluid machinery and characteristic testing, which is applied in the testing of mechanical components, testing of machine/structural components, testing of machine gears/transmission mechanisms, etc. The meshing principle of conventional fluid machinery and the inability to intuitively display the working principle of the meshing pair have achieved the effect of improving the level of experimental teaching, strong application value, and large degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

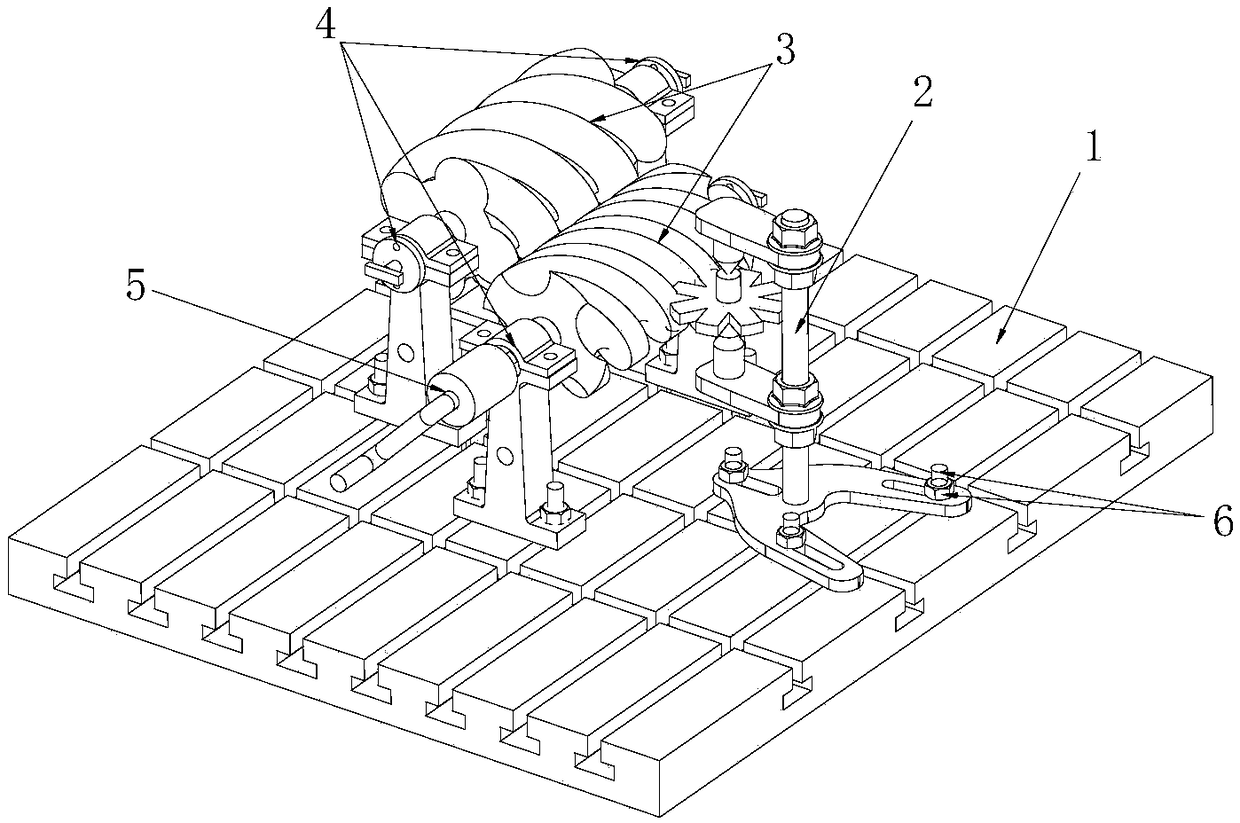

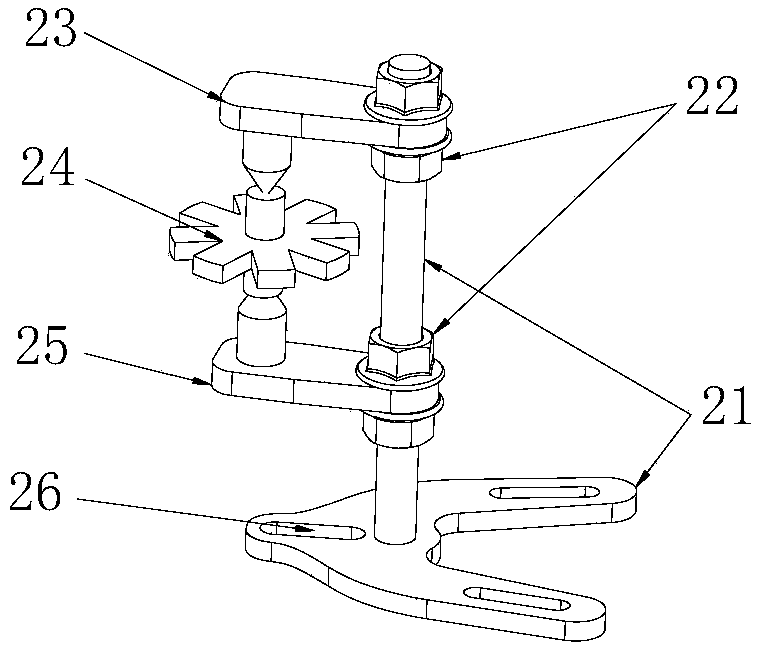

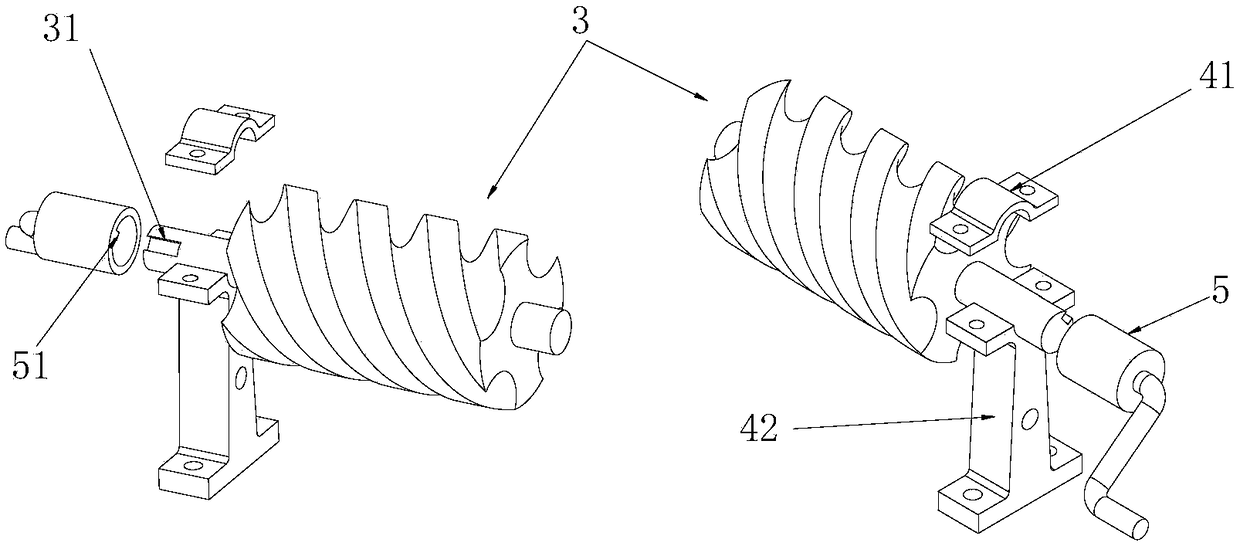

[0019] Such as figure 1 Shown is a test bench for the meshing characteristics of rotary fluid machinery, which mainly includes a staggered T-slot base (1), a vertical axis rotor bracket assembly (2), an meshing rotor (3), an meshing disc (24), a horizontal shaft Rotor support assembly (4), crank handle (5) and fastening assembly (6); vertical axis rotor support assembly (2) and horizontal axis rotor support assembly (4) are connected in a staggered T-shape through fastening assembly (6). On the slot base (1), there are vertically staggered T-shaped slots on the staggered T-slot base (1). Lag bolts can be placed in the T-shaped slots. The lag bolts included in the fastening assembly (6) can be staggered. Free sliding in the T-shaped slot to meet the needs of different installation positions of the bracket components. The lag bolts and nuts can fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com