Electrode formation method for solar battery

A technology for solar cells and electrodes, applied in the field of solar cells, can solve the problems of a large number of masks, complex procedures, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

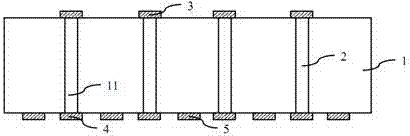

[0027] see Figure 2-19 , solar cell electrode forming method of the present invention, comprises the following steps:

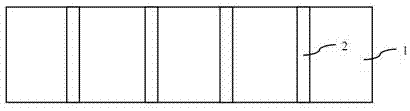

[0028] (1) see figure 2 , providing a battery sheet 1 to be packaged, and forming a conductive through hole 2 connecting the light-receiving surface and the backlight surface of the battery sheet 1;

[0029] (2) see image 3 , providing a first silicon slice 11, the shape and size of the first silicon slice 11 are consistent with the battery slice 1;

[0030] (3) see Figure 4 , coating the first photoresist 12 on the upper surface of the first silicon wafer 11, see Figure 5 , and patterned to form a plurality of first openings 13, the plurality of first openings 13 leaking out of the upper surface of the first silicon wafer 11;

[0031] (4) see Figure 6 , using the photoresist 12 as a mask, etching the first silicon wafer 11 by dry etching to form a plurality of first grooves 14;

[0032] (5) see Figure 7 , removing the first photoresist 12;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com