Degradable blood vessel anastomat provided with drug membrane layer and preparation process of degradable blood vessel anastomat

A preparation process and stapler technology, which is applied in the field of medical devices, can solve the problems that are not conducive to the crawling, growth, and coverage of host vascular intima tissue, poor positioning of vascular staplers, and slow healing speed, etc., to achieve fast and effective Easy connection and anastomosis, fast healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

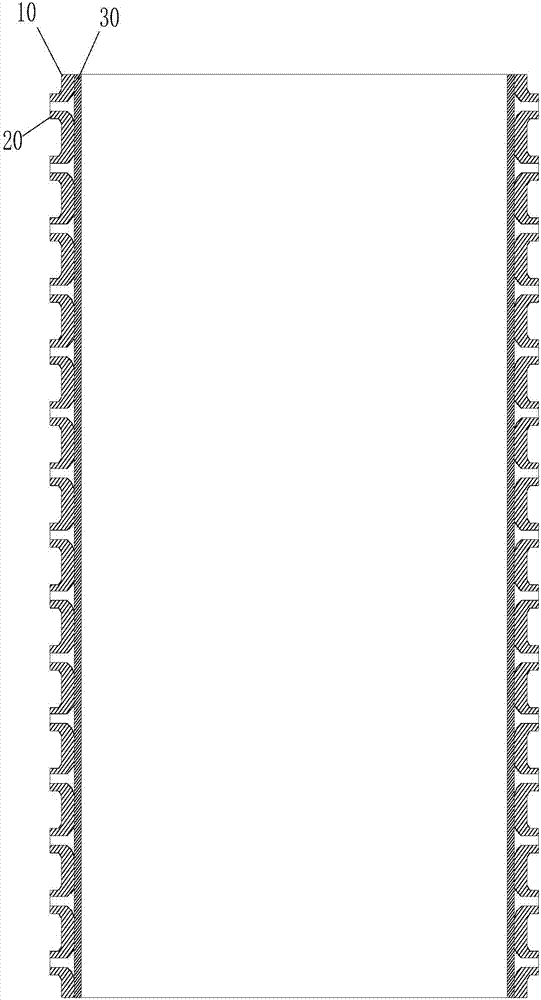

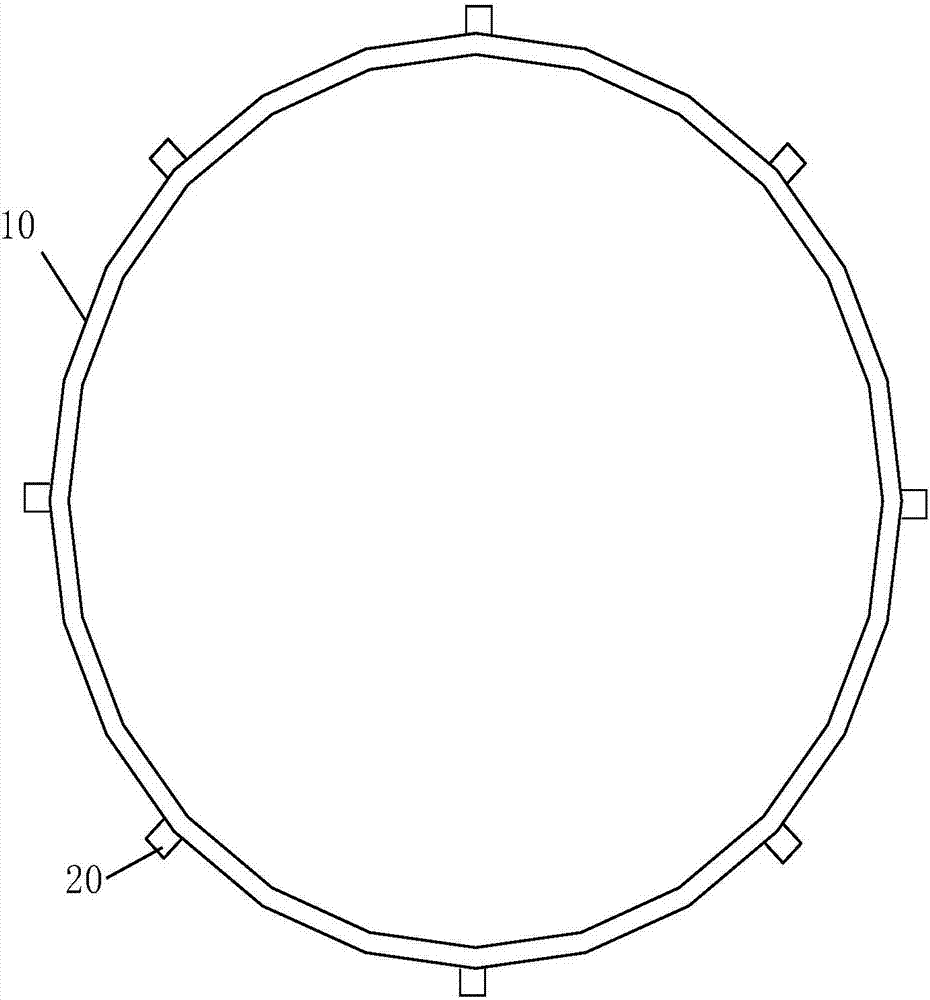

[0029] like Figure 1 to Figure 2 As shown, a degradable vascular stapler with a drug film layer includes a sleeve 10 made of a degradable metal material; the wall of the sleeve 10 is provided with an outwardly protruding perforation structure 20 ; The inner wall of the cannula 10 is provided with a drug film layer 30, and the drug film layer is polyglycolic acid containing anticoagulant drugs.

[0030] The thickness of the drug film layer is 0.1mm. The casing is prepared by a vacuum hot extrusion process, with a wall thickness of 0.1±0.02 mm, a surface roughness of 1.6, and a cylindricity (or straightness) of 0.009. The diameter of the burr hole of the burr hole structure is 0.2 mm, and the height (hole edge) of the burr hole is 0.05 mm. The degradable metal material is Mg-Fe alloy. The outer diameter of the sleeve coincides with the inner diameter of the host blood vessel to be connected.

[0031] A preparation process of a degradable vascular stapler with a drug film la...

Embodiment 2

[0038]A degradable vascular stapler with a drug film layer, including a sleeve made of degradable metal material; the tube wall of the sleeve is provided with an outwardly protruding hole structure; the sleeve of the sleeve Both the inner wall and the outer wall are provided with a drug film layer, and the drug film layer is polylactic acid containing anticoagulant drugs.

[0039] The thickness of the drug film layer is 0.2mm. The casing is prepared by a vacuum hot extrusion process, with a wall thickness of 0.1±0.02 mm, a surface roughness of 1.6, and a cylindricity (or straightness) of 0.009. The diameter of the burr hole of the burr hole structure is 0.2 mm, and the height (hole edge) of the burr hole is 0.05 mm. The degradable metal material is Mg-Zn-Fe alloy. The outer diameter of the sleeve coincides with the inner diameter of the host blood vessel to be connected.

[0040] A preparation process of a degradable vascular stapler with a drug film layer, comprising the f...

Embodiment 3

[0047] A degradable vascular stapler with a drug film layer, including a sleeve made of degradable metal material; the tube wall of the sleeve is provided with an outwardly protruding hole structure; the sleeve of the sleeve A drug film layer is provided on the inner wall and / or the outer wall, and the drug film layer is a collagen film containing an anticoagulant drug or a keratin film containing an anticoagulant drug.

[0048] The thickness of the drug film layer is 0.1mm. The casing is prepared by a vacuum hot extrusion process, with a wall thickness of 0.1±0.02 mm, a surface roughness of 1.6, and a cylindricity (or straightness) of 0.009. The diameter of the burr hole of the burr hole structure is 0.2 mm, and the height (hole edge) of the burr hole is 0.05 mm. The degradable metal material is Mg-Fe alloy. The outer diameter of the sleeve coincides with the inner diameter of the host blood vessel to be connected.

[0049] A preparation process of a degradable vascular st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com