Low-k material laser removal process and its equipment

A 1.low-k, laser technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as poor effect, achieve optimized processing effect, good processing cutting track shape, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

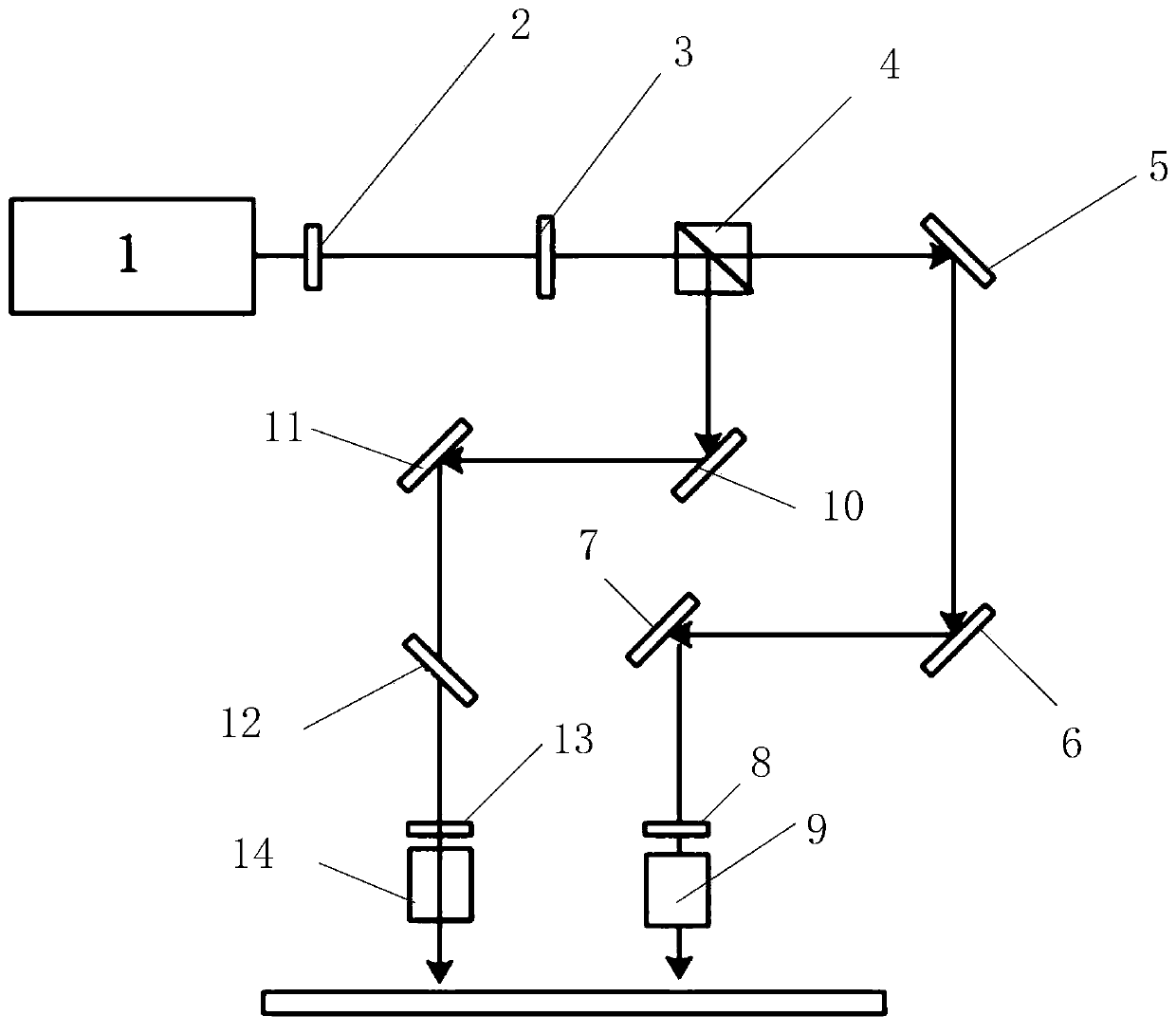

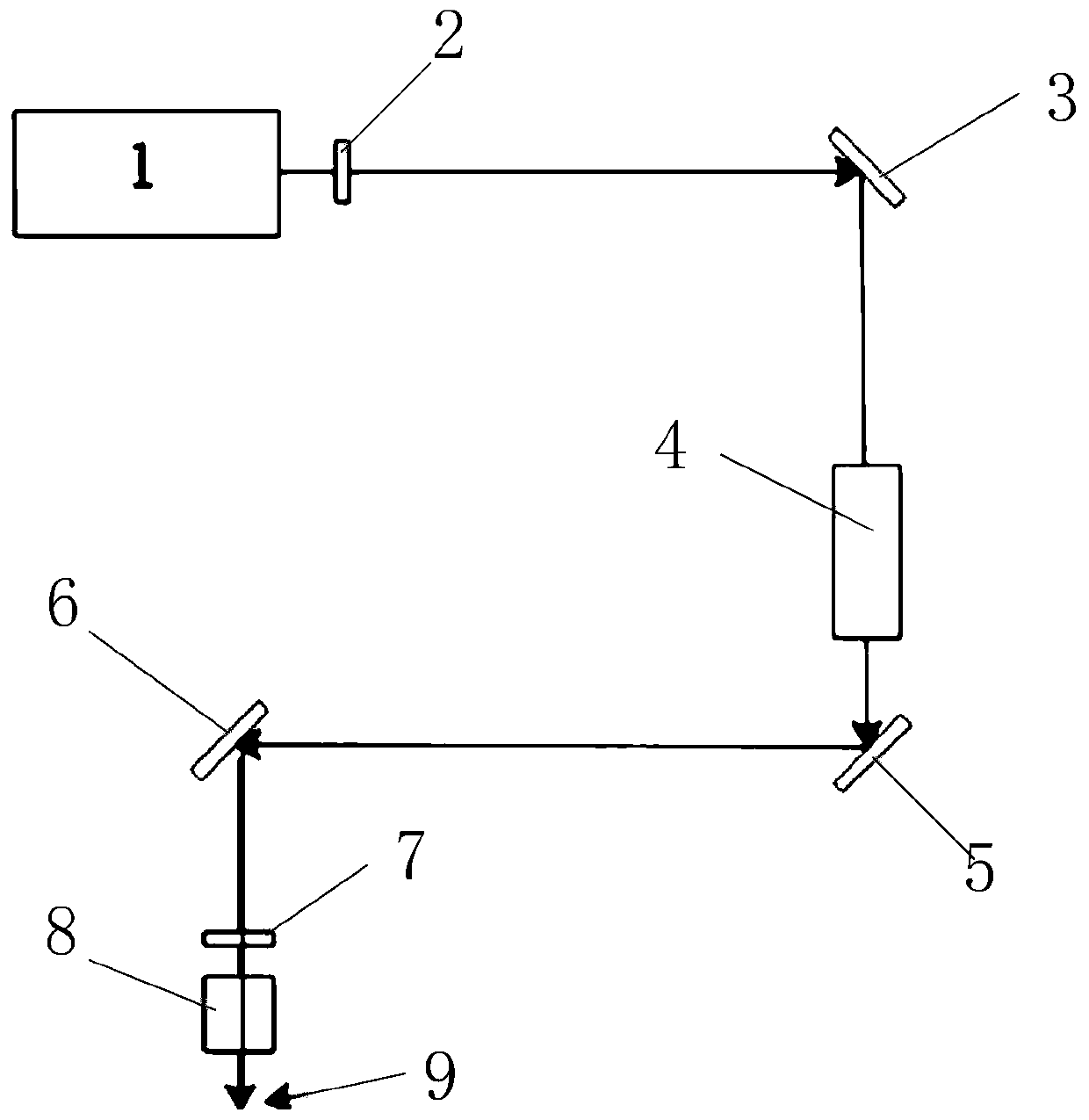

[0041] A 355nm ultraviolet laser with an output power of 12W and a pulse width of 90ns is used. The laser beam is transmitted to the half-wave plate 3 through the opened shutter 2, and then becomes linearly polarized light with adjustable polarization direction. The linearly polarized light is divided into two beams of laser light after passing through the polarization beam splitter 4, and the P light can directly pass through the polarization beam splitter. The mirror 4 continues to propagate, and the S light is reflected by the polarization beam splitter 4 and then enters the first reflector 10 to form two paths of independently propagating laser light.

[0042]The middle half-wave plate 3 is driven by a servo motor and can rotate 360 degrees. During the rotation, the power of the transmitted P light and the reflected S light changes. The P light separated from the laser beam passes through the reflector 5 and continues to propagate to the reflector 6 and the reflector 7, ...

Embodiment 2

[0045] The laser used has a wavelength of 355nm and a variable pulse width of 20-120ns. The laser can also be an ultrashort pulse laser with a wavelength range of 355nm-1070nm.

[0046] During the implementation period, the half-wave plate is driven by a servo motor, installed in a circular mechanism, driven by the motor to rotate, and the rotation accuracy is not less than 0.5 degrees. In this way, as the angle changes, the output power of the polarizing beam splitter 4 will continue to change, where the polarizing beam splitter 4 can be a polarizing cube or a film polarizer.

[0047] Furthermore, the first focusing lens 9 and the second focusing lens 14 used can be combined into one, further improving the processing efficiency. At the same time, the polarization beam splitter 4 can also be driven by a ceramic motor to meet the high-precision 360-degree rotation. With the change of the angle of the beam splitter, the distance between the scribing spot relative to the platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com