Wax-printing printing-resistant wax applicable to linen and preparation method of wax-printing printing-resistant wax

A batik dyeing and anti-dying technology, applied in the field of batik dyeing process, can solve the problems of uneven waxing, low adhesion, poor permeability, etc., and achieve the effect of low resin content, low viscosity and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

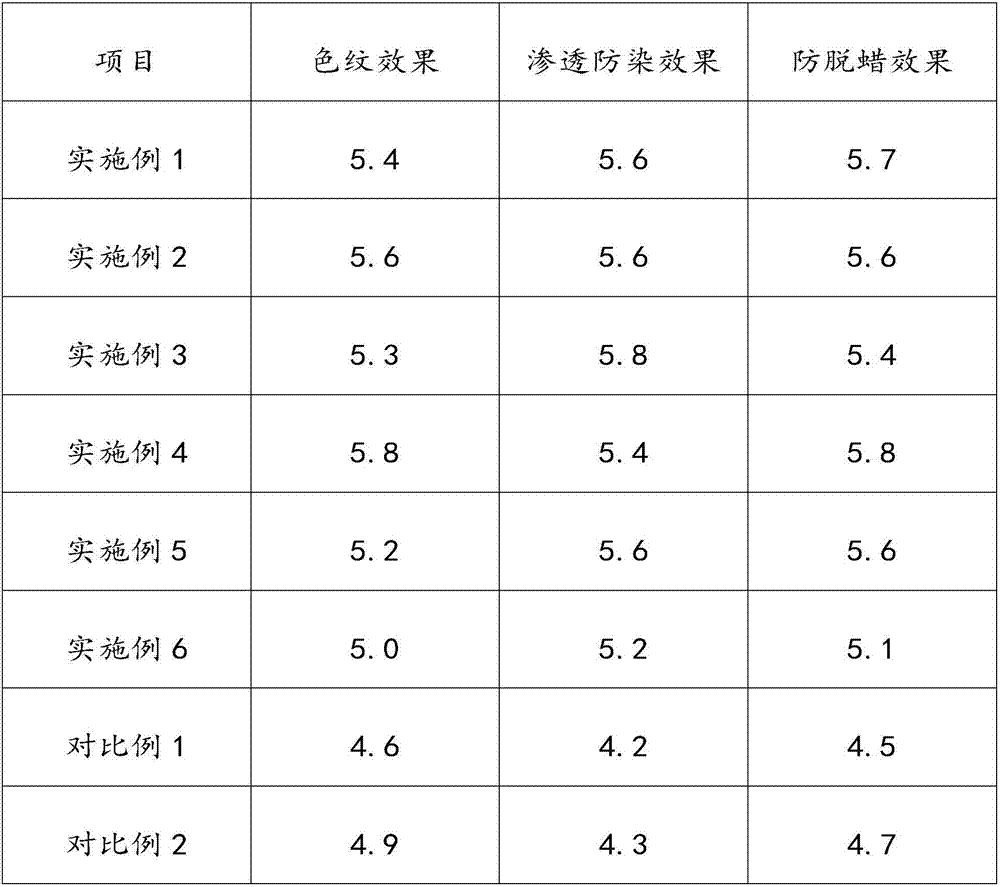

Examples

preparation example Construction

[0024] The preparation method of the batik anti-dyeing wax suitable for linen comprises: weighing 30-40 parts by weight of paraffin wax and 10-20 parts by weight of beeswax, heating to 70-80°C to melt and keeping it warm for 0.5-1h to obtain the first mixture; Take 5-10 parts by weight of palm wax, 2-4 parts by weight of dammar resin and 5-8 parts by weight of stearic acid, 1-1.5 parts by weight of suet and 0.5-1 parts by weight of carboxymethyl cellulose Heat the sodium to 140-150°C to melt and keep it warm for 0.5-1h to obtain the second mixture; add the first mixture to the second mixture at a temperature of 120-130°C, stir at 400-600r / min for 20-30min, and cool.

[0025] After the first mixture and the second mixture are mixed, Pingpingjia and Span are added, and the first mixture and the second mixture are uniformly dispersed during the stirring process, so as to improve the uniformity of the internal structure of the anti-dyeing wax material.

[0026] Since paraffin wax ...

Embodiment 1

[0034] A preparation method for batik anti-dye wax suitable for linen, comprising:

[0035]Weigh 30 parts by weight of paraffin and 10 parts by weight of beeswax, mix and heat the beeswax and 20g of water to 65-75°C to melt, then let it stand for cooling, take out the purified beeswax, and heat the paraffin and purified beeswax to 70-80°C ℃ melting and insulated for 0.5-1h to obtain the first mixture; weigh 5 parts by weight of palm wax, 2 parts by weight of dammar resin, 5 parts by weight of stearic acid, 1 part by weight of suet and 0.5 parts by weight of carboxymethyl Sodium cellulose was heated to 140-150°C to melt and kept warm for 0.5-1h to obtain the second mixture; at a temperature of 120-130°C, the first mixture was added to the second mixture, and then 0.5 parts by weight of Pingpingjia and 0.3 parts by weight of Span, stir at 400-600r / min for 20-30min. Cool under the pressure of 0.2-0.3MPa.

Embodiment 2

[0037] Weigh 33 parts by weight of paraffin and 12 parts by weight of beeswax, mix and heat beeswax and 24g of water to 65-75°C and melt, then let it stand for cooling, take out the purified beeswax, and heat the paraffin and purified beeswax to 70-80°C ℃ melting and keeping warm for 0.5-1h to obtain the first mixture; weigh 7 parts by weight of palm wax, 2.5 parts by weight of dammar resin, 6 parts by weight of stearic acid, 1.1 parts by weight of sheep oil and 0.6 parts by weight of carboxymethyl Sodium cellulose was heated to 140-150°C to melt and kept warm for 0.5-1h to obtain the second mixture; at a temperature of 120-130°C, the first mixture was added to the second mixture, and then 0.6 parts by weight of Pingpingjia and 0.35 parts by weight of Span, stir at 400-600r / min for 20-30min. Cool under the pressure of 0.2-0.3MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com