TE die polarization analyzer based on symmetrical three-waveguide directional coupler structure

A directional coupler and waveguide technology, applied in the field of integrated optics, can solve the problems of high ohmic loss and high insertion loss that are not conducive to large-scale production and cost, and achieve the effects of compact structure, low insertion loss, and reduced insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

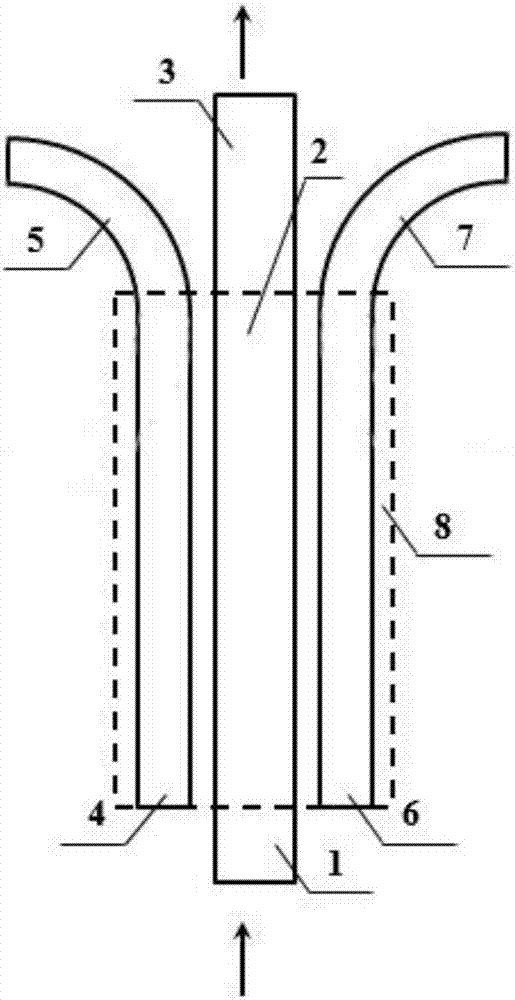

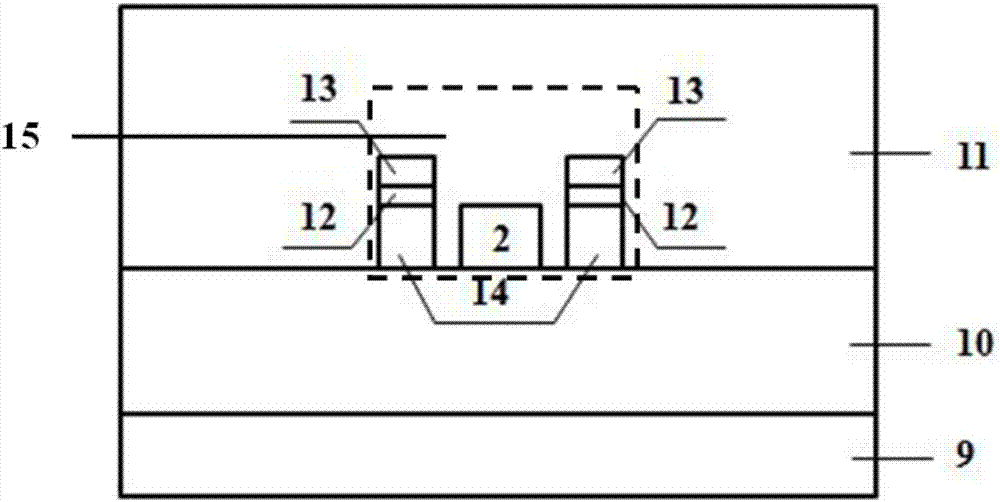

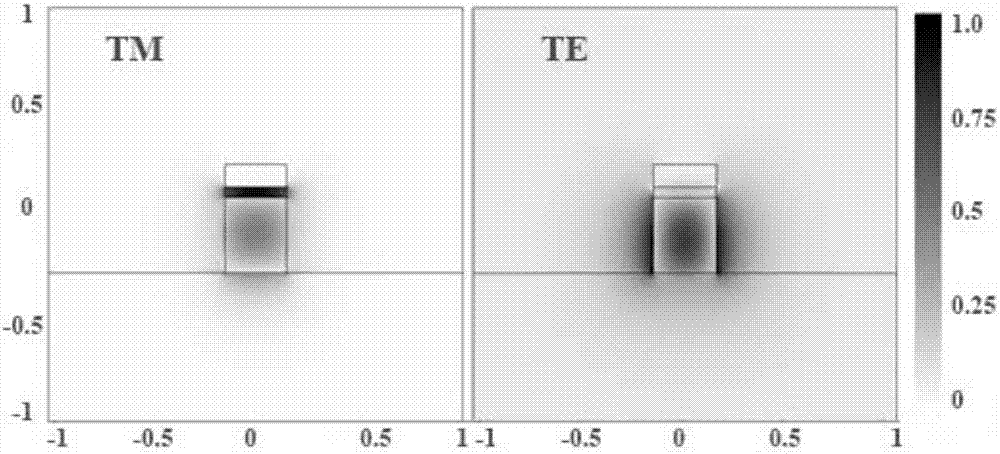

[0038] Such as figure 1 with figure 2 As shown, the analyzer consists of a silicon-based substrate 9, a buried oxide layer 10, an analyzer component 15, and an upper cladding layer 11 from bottom to top, wherein the buried oxide layer 10 is grown on the upper surface of the silicon-based substrate 9, and the upper cladding layer 11 is The cladding layer 11 covers the upper surface of the buried oxide layer 10, and the analyzer component 15 grows horizontally on the upper surface of the buried oxide layer 10 and is covered by the upper cladding layer 11;

[0039] The polarization analysis unit 15 includes an input channel 1, a middle straight channel 2, a left straight channel 4, a left C-shaped curved channel 5, a right straight channel 6, a right C-shaped curved channel 7, and an output channel 3;

[0040] One end of the middle direct channel 2 is connected to the input channel 1, and the other end is connected to the output channel 3 to form a middle channel;

[0041] The...

Embodiment 2

[0055] Such as Figure 9 As shown in the schematic structural diagram of the improved polarization analyzer 15 (silicon-based substrate 9, buried oxide layer 10, and upper cladding layer 11 are identical to those of Embodiment 1), the improved polarization analyzer 15 includes an input channel 1, a middle through channel 2. Left straight channel 4, left C-shaped curved channel 5, right straight channel 6, right C-shaped curved channel 7, output channel 3;

[0056] One end of the middle direct channel 2 is connected to the input channel 1, and the other end is connected to the output channel 3 to form a middle channel;

[0057] The left straight-through channel 4 is connected to the left C-shaped curved channel 5, and the right straight-through channel 6 is connected to the right C-shaped curved channel 7; wherein, the output channel 3, the left C-shaped curved channel 5, and the right C-shaped curved channel 7 at the same end;

[0058] The left through channel 4 and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com