Reproduced nutritional rice and preparation method thereof

A technology for nutritious rice and corn, applied in the functions of food ingredients, food science, application, etc., can solve the problems of unsuitable taste, lack of protein nutrition, lack of rice, etc., to achieve convenient eating, rich in nutrients, and suitable for a wide range of people. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

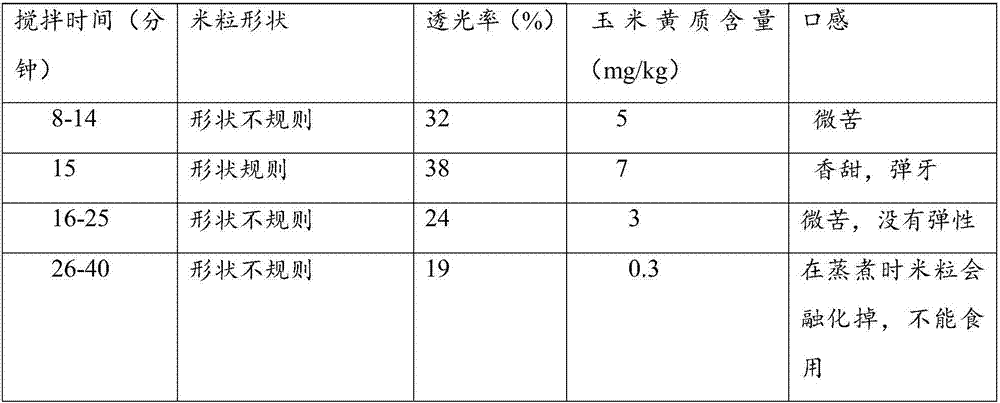

[0021] Embodiment 1 The preparation of rebuilding nutritional rice

[0022] (1) After removing dust and impurities from corn, buckwheat, pumpkin and red beans, they are ultrafinely pulverized into powder;

[0023] (2) Weigh each component (unit: Kg) according to the following parts by weight: corn 50, buckwheat 20, pumpkin 17, red bean 13;

[0024] (3) Mix the components uniformly to obtain a mixture 1; (4) add water to the mixture 1 and stir to obtain a mixture 2, wherein the ratio of the mixture 1 to water is 100:21, and the mixing and stirring time is controlled to 15 minutes; (5) After the mixture 2 is extruded and pre-gelatinized in the screw granulator, it is extruded and diced; the temperature of the screw granulator from the granulation to the granulation body is: the temperature in zone 1 is: 95 -100°C, temperature in Zone 2 195-200°C, temperature in Zone 3 95-100°C; (6) After natural cooling, the rice grains cut from the discharge end of the screw granulator enter t...

Embodiment 2

[0025] Embodiment 2 The preparation of rebuilding nutritional rice

[0026] (1) After removing dust and impurities from corn, buckwheat, pumpkin and red beans, they are ultrafinely pulverized into powder;

[0027] (2) Take each component (unit: Kg) according to the following parts by weight: corn 42, buckwheat 17, pumpkin 15, red bean 8;

[0028] (3) Mix the components uniformly to obtain a mixture 1; (4) add water to the mixture 1 and stir to obtain a mixture 2, wherein the ratio of the mixture 1 to water is 100:22, and the mixing and stirring time is controlled to 8 minutes; (5) After the mixture 2 is extruded and pre-gelatinized in the screw granulator, it is extruded and diced; the temperature of the screw granulator from the granulation to the granulation body is: the temperature in zone 1 is: 95 -100°C, temperature in Zone 2 195-200°C, temperature in Zone 3 95-100°C; (6) After natural cooling, the rice grains cut from the discharge end of the screw granulator enter the ...

Embodiment 3

[0029] Embodiment 3 The preparation of rebuilding nutritional rice

[0030] (1) After removing dust and impurities from corn, buckwheat, pumpkin and red beans, they are ultrafinely pulverized into powder;

[0031] (2) Take each component (unit: Kg) according to the following parts by weight: corn 60, buckwheat 40, pumpkin 50, red bean 15;

[0032] (3) Mix the components uniformly to obtain a mixture 1; (4) add water to the mixture 1 and stir to obtain a mixture 2, wherein the ratio of the mixture 1 to water is 100:20, and the mixing and stirring time is controlled to 40 minutes; (5) After the mixture 2 is extruded and pre-gelatinized in the screw granulator, it is extruded and diced; the temperature of the screw granulator from the granulation to the granulation body is: the temperature in zone 1 is: 95 -100°C, temperature in Zone 2 195-200°C, temperature in Zone 3 95-100°C; (6) After natural cooling, the rice grains cut from the discharge end of the screw granulator enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com