Ecological environmental protection system for redrying industry

An ecological and environmentally friendly technology, applied in the direction of combined devices, gas treatment, membrane technology, etc., can solve the problems of dust collector blockage, high dust volume, large particle dust, etc., achieve safe and convenient use, stable use effect, and improve treatment quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and cannot limit the protection scope of the present invention with this.

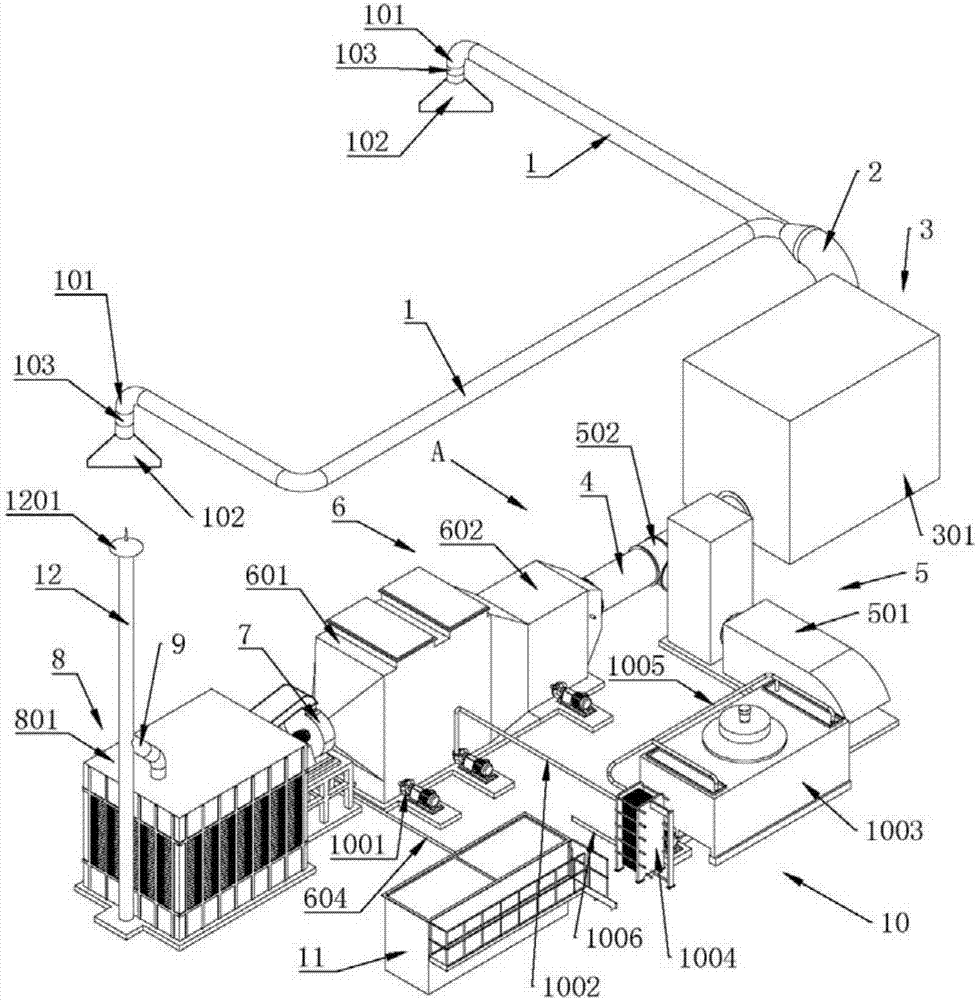

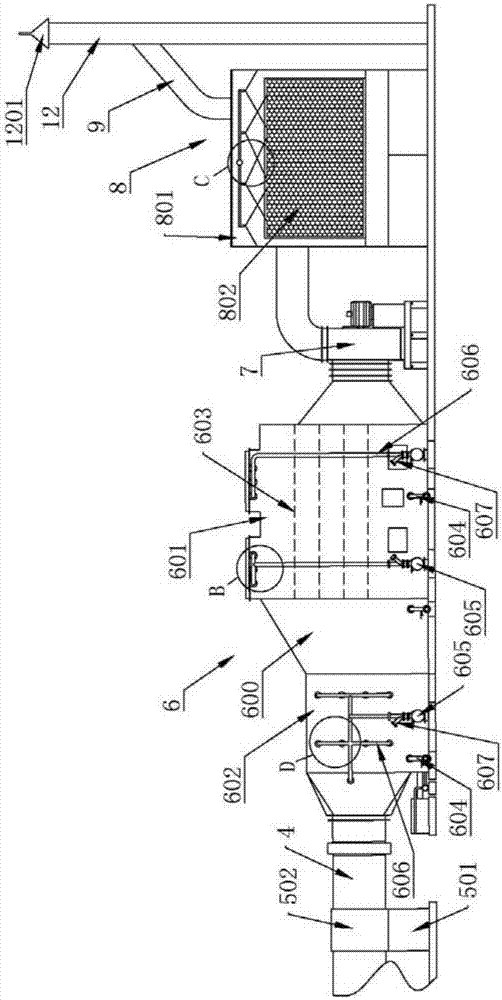

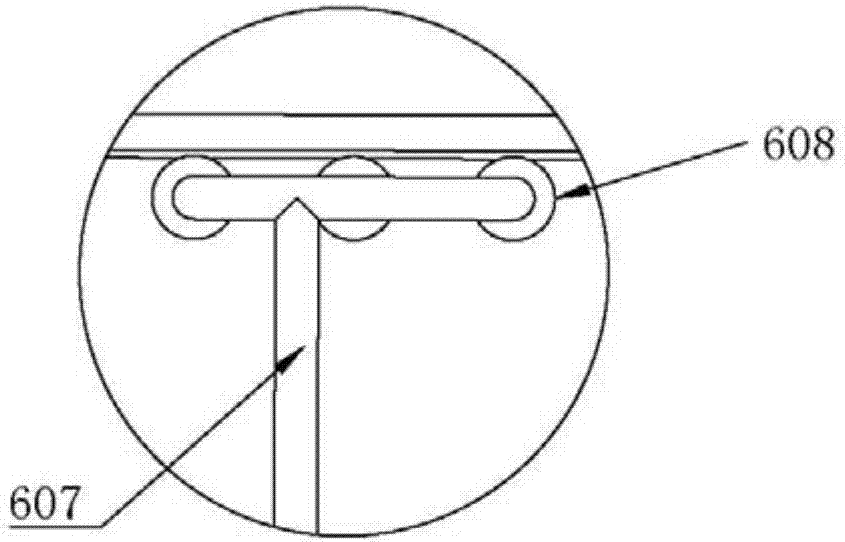

[0046] Such as figure 1 As shown, the eco-environmental protection system for the rebaking industry includes at least one intake pipe 1 extending to the workshop at one end. The extension pipe 101 extending in the direction of the workbench in the region), the extension pipe 101 is provided with a gas collection hood 102, and the extension pipe 101 above the gas collection hood 102 is provided with an air volume regulating valve 103; the other ends of all the intake pipes 1 are Connected with the intake manifold 2, the diameter of the intake manifold 2 is greater than the diameter of the intake manifold 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com