A porous hydroxyapatite/titanium nitride bioactive coating capable of shielding release of harmful ions and its application

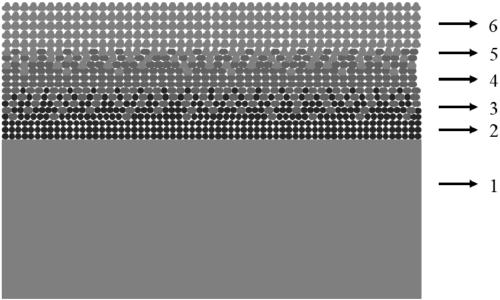

A technology of porous hydroxyapatite and hydroxyapatite, which is applied in the direction of coating, ion implantation plating, metal material coating technology, etc., can solve the problem of poor uniformity of coating prepared by laser cladding, difficulty in reaching 15.0MPa, plasma Spraying pyrolysis and other issues to achieve the effect of improving biocompatibility and biological activity, improving wear resistance, enhancing wear resistance and corrosion resistance and biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

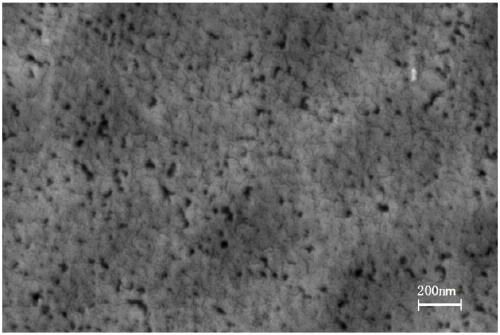

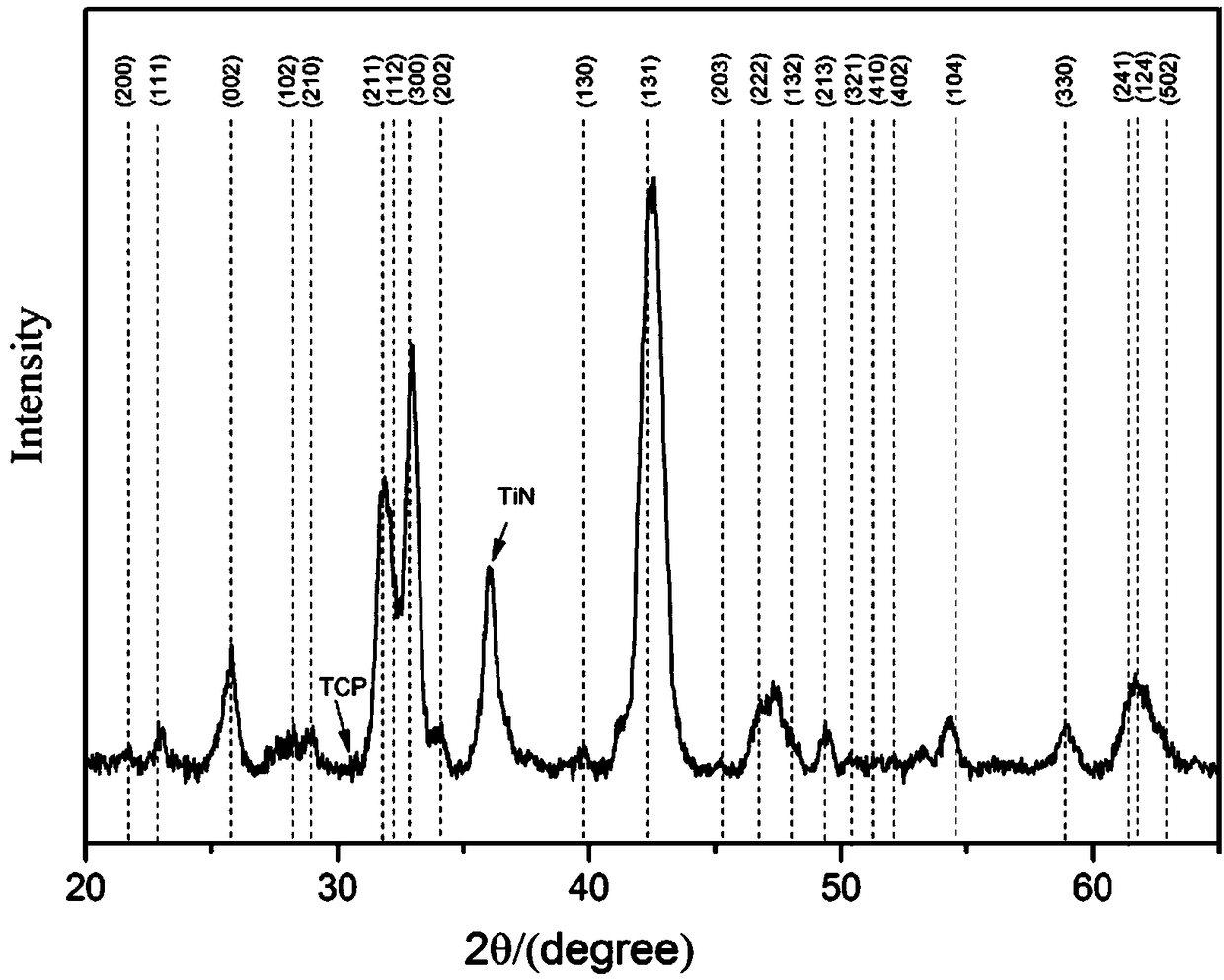

Examples

Embodiment 1

[0057] Use Ti-6Al-4V alloy, which is often used as bone plate, bone nail, and artificial joint replacement material, as the base material and follow the steps below:

[0058] (1) Cut the titanium alloy into φ30.0×3.0mm 3 Grind and polish the disc with 400#, 800#, 1200#, 1500#, 2000# diamond sandpaper, then wash it with distilled water, alcohol and acetone for 30.0min respectively, and then soak it in 3.0mol / L KOH lye 24.0 hours, then continue ultrasonic cleaning with distilled water for 40.0 minutes, and finally dry at 40.0°C for 24.0 hours for later use.

[0059] (2) Clean the substrate and target, install the substrate, high-purity Ti target and hydroxyapatite target in the vacuum sputtering chamber, and evacuate to 5.0×10 -5 Pa, argon gas is introduced into the sputtering chamber, the flow rate is 100.0sccm, the argon pressure in the sputtering chamber is maintained at 0.6Pa, and the position of the substrate is adjusted so that it faces away from the target; the bias volt...

Embodiment 2

[0066] Use 316L stainless steel, which is often used as bone plate, bone nail, and artificial joint replacement material, as the base material and follow the steps below:

[0067] (1) Cut 316L stainless steel into 30.0×30.0×2.0mm 3 Grind and polish the disc with 400#, 800#, and 1200# diamond sandpaper, then wash with distilled water, alcohol, and acetone for 30.0 minutes, and finally dry it at 40.0°C for 24.0 hours before use.

[0068] (2) Clean the substrate and target, install the substrate, high-purity titanium target and hydroxyapatite target in the vacuum sputtering chamber, and evacuate to 3.0×10 -5 Pa, argon gas is introduced into the sputtering chamber, the flow rate is 120.0sccm, the argon pressure in the sputtering chamber is maintained at 0.8Pa, and the position of the substrate is adjusted to make it face away from the target; The substrate is cleaned and activated by argon ion discharge for 30.0 minutes; the bias power is turned off, and the titanium target and hyd...

Embodiment 3

[0075] Use CoCrMo alloy, which is often used as artificial joint replacement material, as the base material and follow the steps below:

[0076] (1) Cut the CoCrMo alloy substrate into φ30.0×3.0mm 3 Grind and polish the wafer with 400#, 800#, 1200#, 1500# diamond sandpaper, then wash it with distilled water, alcohol and acetone for 30.0 minutes, then soak it in 3.0mol / L KOH lye for 24.0 hours, Then continue ultrasonic cleaning with distilled water for 40.0 minutes, and finally dry at 40.0° C. for 24.0 hours for use.

[0077] (2) Clean the target and substrate according to the process described in step 2 in Example 2.

[0078] (3) Deposit titanium as a bottom layer, adjust the substrate to face the target, turn on the titanium target and bias power, control the current to 3.0A, bias to -500.0V, maintain the argon pressure at 0.8Pa, and the flow rate at 150.0sccm , deposit titanium as a bottom layer on the substrate, and the deposition time is 2.0 minutes.

[0079] (4) Deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap