Novel high-speed electromagnetic valve for reciprocating compressor and assembly method of novel high-speed electromagnetic valve

A technology for high-speed solenoid valves and compressors, applied in valve devices, fluid pressure actuating devices, valve operation/release devices, etc., can solve problems such as damage to internal injection molding materials, potential safety hazards, external leakage, etc., and achieve reduction The effect of power transmission path, volume and weight reduction, and high magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

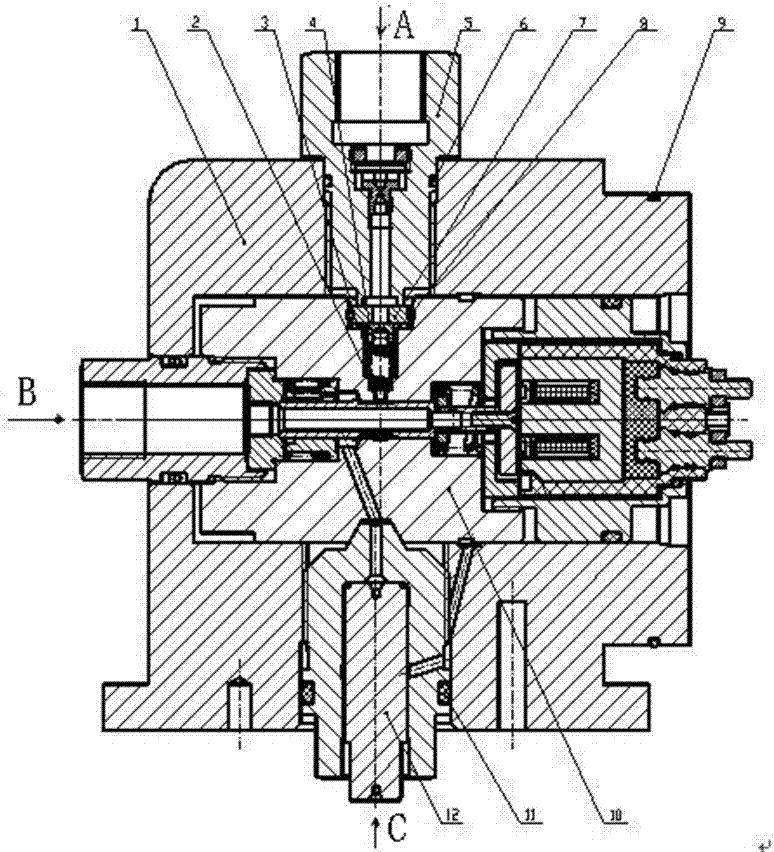

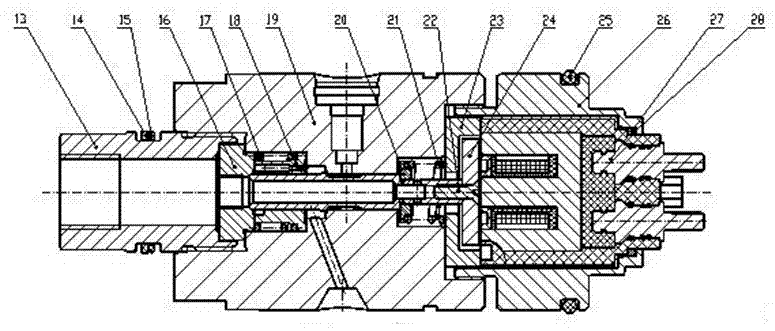

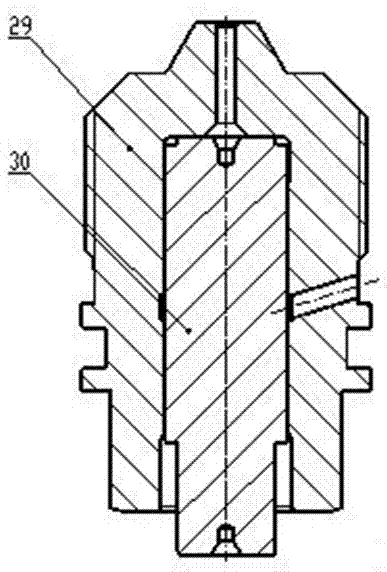

[0067] The specific implementation, features and effects of a new high-speed solenoid valve for a reciprocating compressor and its assembly method according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0068] see Figure 1-19 , a new type of high-speed solenoid valve for reciprocating compressors, including a housing 1, a check valve spring 2, a copper pad 3, a check valve 4, an oil inlet pipe joint assembly 5, an O-ring A6, a check valve valve Seat 7, O-ring B8, O-ring C9, electromagnet assembly 10, O-ring D11 and piston assembly 12, the electromagnet assembly 10 includes: oil outlet pipe joint 13, sealing retaining ring 14, O-ring E15, seal seat 16, oil outlet spring 17, oil outlet spring seat 18, valve body assembly 19, spring seat 20, spring 21, screw 22, support seat assembly 23, armature 24, O-ring F25, coil housing 26 , electromagnet 27, O-ring G28; the electromagnet 27 includes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com