Equivalent loading experimental device capable of realizing shock compression of material underwater explosion shock waves

A technology for underwater explosion and loading experiments, which is applied to measuring devices, impact testing, and analyzing materials, etc. It can solve the problems of high experimental environment requirements, high risk factors, and poor controllability, and achieve strong operability and high safety. , reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with examples in conjunction with the accompanying drawings.

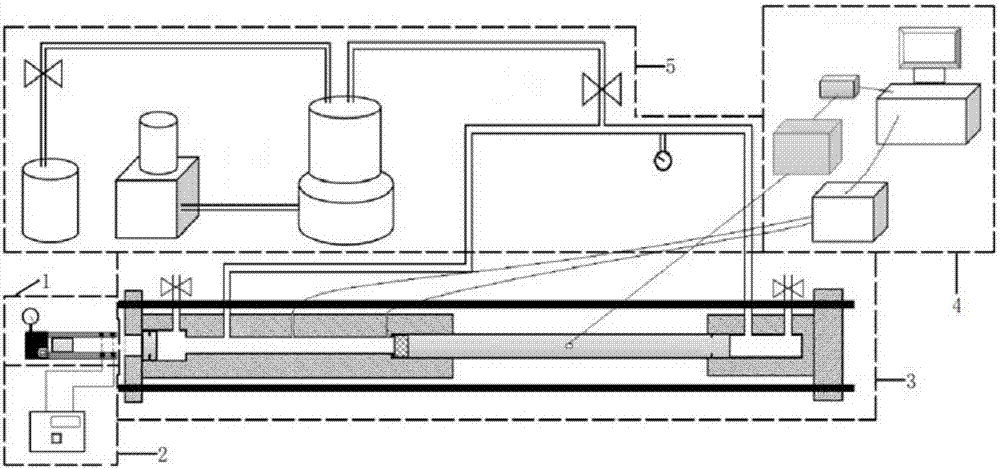

[0025] combine figure 1 , The test system of the present invention includes five main parts such as a launch system 1, a speed measurement system 2, a high-pressure water tank system 3, a measurement system 4, and a hydraulic system 5. The launch system and the water tank system are horizontally arranged in a straight line, the launch tube port of the loading system is opposite to the head port of the test water tank, and the laser velocity measurement system is fixedly installed at the end of the launch tube wall. The water tank system is horizontally fixed and installed on the cement base by a plurality of annular brackets.

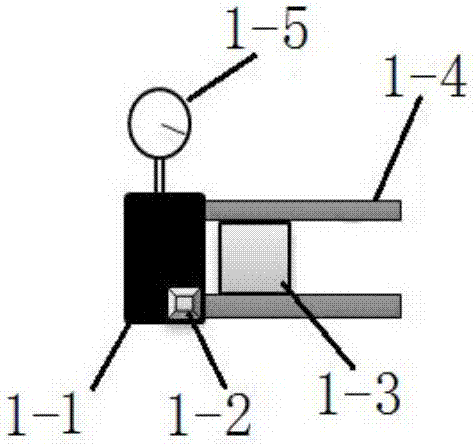

[0026] combine figure 2 , the launch system includes components such as high-pressure gas chamber 1-1, trigger switch 1-2, bullet 1-3, launch tube 1-4, gas chamber pressure gauge 1-5, and the gas chamber pressure gauge is instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com