Test bench for peaking shaft type multi-specification rolling bearing clamped by electric cylinders

A rolling bearing and test bench technology, applied in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of high time and economic costs, and achieve convenient processing and disassembly, and convenient installation and disassembly tests , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

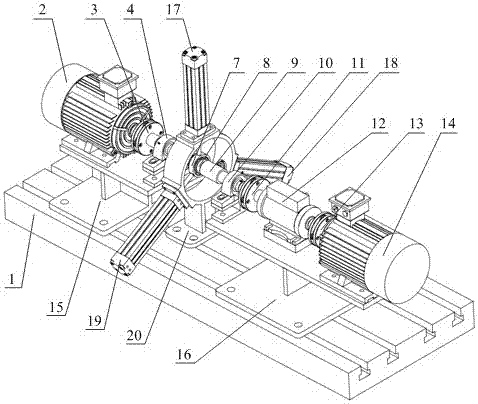

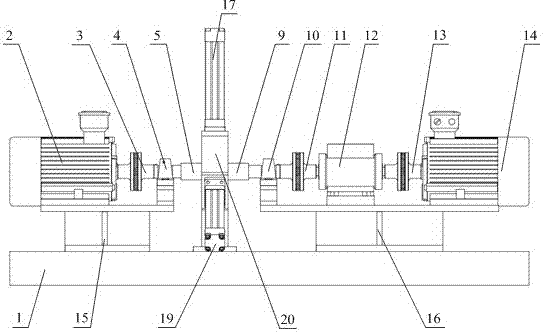

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

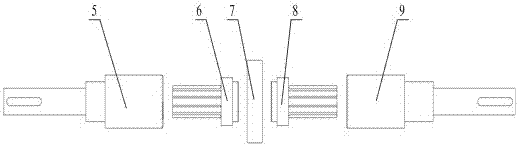

[0026] refer to Figure 1~Figure 7 , a servo electric cylinder clamping multi-standard rolling bearing test bench installed on a stepped shaft, characterized in that it includes a base platform 1, a driving motor 2, a first set of shafts 5, a first top shaft 6, a test rolling bearing 7, and a second set of shafts. Two top shafts 8, a second sleeve shaft 9, a torque tachometer 12, a loading motor 14 and three servo electric cylinders 17, 18, 19.

[0027] In this embodiment, the test rolling bearing 7 is a 6006 deep groove ball bearing with an inner diameter of 30 mm, an outer diameter of 55 mm and a width of 15 mm. The diameter of the stepped shafts of the first top shaft 6 and the second top shaft 8 is the same as the inner diameter of the test rolling bearing 7, the length of the stepped shafts is 5mm, and the sum of the lengths of the stepped shafts is less than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com