Special substrate for FPC boards

A flexible circuit board and base material technology, applied in the field of materials, can solve problems such as cost increase, FPC circuit board short circuit, FPC circuit board production yield reduction, etc., to achieve the effect of improving service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of release agent:

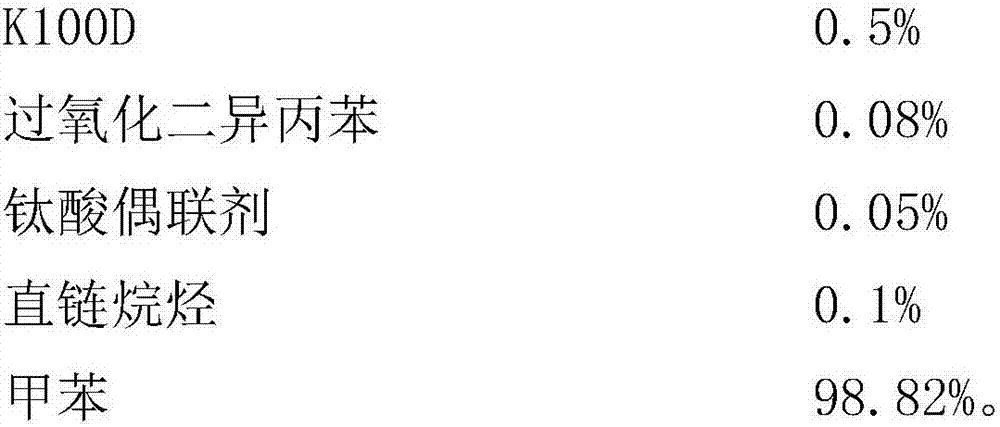

[0026] Weigh the raw materials in the following weight percentages,

[0027]

[0028] Add K100D (Shanghai Jiteng Chemical Co., Ltd.) to toluene, stir, then add dicumyl peroxide, titanic acid coupling agent, and straight-chain alkanes (the number of carbon atoms is 20), and stir for 60-90 minutes, let it sit.

[0029] (2) Preparation of release film layer:

[0030] Put the polyester film on the roller shaft of the adhesive machine and unwind it, the unwinding speed is 35 m / min, dry, coat the release agent on the polyester film, the coating amount is 0.2 g / square meter, pass through In the drying section, the temperature is 80°C, 100°C, 120°C, 150°C, 150°C, 150°C, 120°C, 80°C, cooling, winding, and the winding speed is 35 m / min.

[0031] (3) Preparation of special base materials for FPC flexible circuit boards:

[0032] Coating 10 microns of epoxy resin composite glue layer on the PI film layer surface with a thickness of 25 micr...

Embodiment 2

[0035] (1) Preparation of release agent:

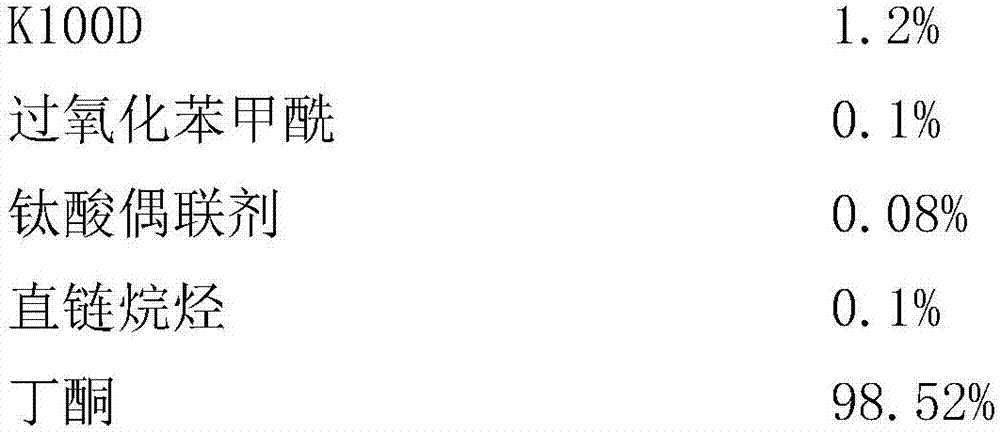

[0036] Weigh the raw materials in the following weight percentages,

[0037]

[0038] Add K100D to butanone, stir, then add benzoyl peroxide, titanic acid coupling agent, and straight-chain alkanes (with 25 carbon atoms) in sequence, stir and react for 60-90 minutes, and let stand.

[0039] (3) Preparation of release film layer:

[0040] Put the polyester film on the roller shaft of the adhesive machine and unwind it, the unwinding speed is 35 m / min, dry, coat the release agent on the polyester film, the coating amount is 0.2 g / square meter, pass through In the drying section, the temperature is 80°C, 100°C, 120°C, 150°C, 150°C, 150°C, 120°C, 80°C, cooling, winding, and the winding speed is 35 m / min.

[0041] (3) Preparation of special base materials for FPC flexible circuit boards:

[0042] Coating 15 microns of epoxy resin composite glue layer on the PI film layer surface with a thickness of 30 microns, then bonding 20 microns...

Embodiment 3

[0045] (1) Preparation of release agent:

[0046] Weigh the raw materials in the following weight percentages,

[0047]

[0048] Add K100D to ethyl acetate, stir, then add benzoyl peroxide, titanic acid coupling agent, and linear alkanes (with 22 carbon atoms) in sequence, stir for 60-90 minutes, and let stand.

[0049] (4) Preparation of release film layer:

[0050] Put the polyester film on the roller shaft of the adhesive machine and unwind it, the unwinding speed is 35 m / min, dry, coat the release agent on the polyester film, the coating amount is 0.2 g / square meter, pass through In the drying section, the temperature is 80°C, 100°C, 120°C, 150°C, 150°C, 150°C, 120°C, 80°C, cooling, winding, and the winding speed is 35 m / min.

[0051] (3) Preparation of special base materials for FPC flexible circuit boards:

[0052] Coating the PI film layer surface with a thickness of 20 microns with an epoxy resin composite glue layer of 8 microns, then bonding a 20 micron copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com