Fermentation process of fresh soy sauce

A fermentation process and soy sauce technology, which is applied in the field of fresh soy sauce fermentation process, can solve the problems of color deepening, soy sauce aroma substances, trace alcohol content reduction, etc., and achieve the effect of improving flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

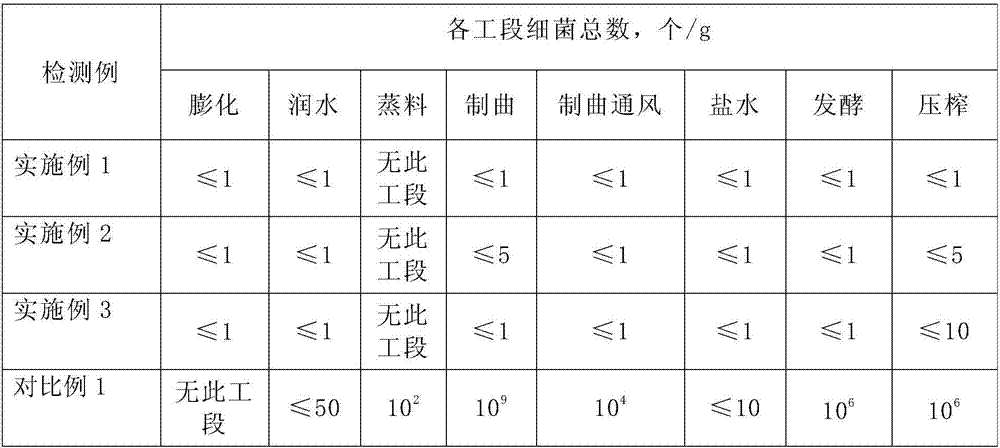

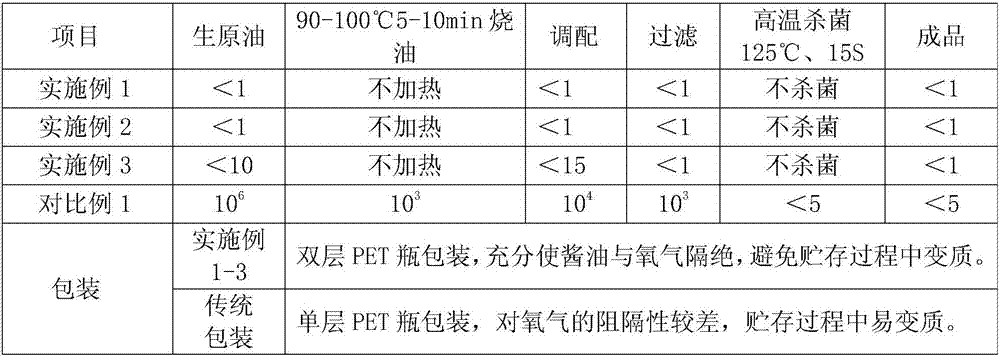

Embodiment 1

[0040] A fresh soy sauce fermentation process, comprising the following steps:

[0041] 1) Raw material puffing: Send 1 ton of high-quality soybeans and wheat into a rotary cooker for dry steaming at a temperature of 130°C and a pressure of 0.2Mpa for 10 minutes, and release the pressure to obtain puffed soybeans and wheat;

[0042] 2) Moisturizing: Add 1.6 tons of sterile water at 70°C to the puffed soybeans and wheat, so that the raw materials can fully absorb water and facilitate koji making;

[0043]3) Inoculation and koji making: the moistened raw materials enter the continuous mixing tank, add sterile seed koji and mix evenly, and the evenly mixed materials are transported to the aseptic disc koji making machine through sterile pipelines, and the wind of the koji making machine Use after filtering through a filter to avoid contamination by bacteria. The koji making temperature is 20°C and the koji making time is 55 hours;

[0044] 4), salt water freezing: after the salt...

Embodiment 2

[0051] A fresh soy sauce fermentation process, comprising the following steps:

[0052] 1) Raw material puffing: put 1 ton of high-quality soybeans and wheat into a rotary cooker for dry steaming at a temperature of 128°C and a pressure of 0.18Mpa for 13 minutes, and release the pressure to obtain puffed soybeans and wheat;

[0053] 2) Moisturizing: Add 1.8 tons of sterile water at 75°C to the puffed soybeans and wheat, so that the raw materials can fully absorb water and facilitate koji making;

[0054] 3) Inoculation and koji making: the moistened raw materials enter the continuous mixing tank, add sterile seed koji and mix evenly, and the evenly mixed materials are transported to the aseptic disc koji making machine through sterile pipelines, and the wind of the koji making machine Use after filtering through a filter to avoid contamination by bacteria. The koji making temperature is 23°C and the koji making time is 53 hours;

[0055] 4), salt water freezing: After the sal...

Embodiment 3

[0062] A fresh soy sauce fermentation process, comprising the following steps:

[0063] 1) Raw material puffing: put 1 ton of high-quality soybeans and wheat into a rotary cooker for dry steaming at a temperature of 126°C and a pressure of 0.17Mpa for 15 minutes, and release the pressure to obtain puffed soybeans and wheat;

[0064] 2) Moisturizing: Add 2.0 tons of sterile water at 80°C to the puffed soybeans and wheat, so that the raw materials can fully absorb water and facilitate koji making;

[0065] 3) Inoculation and koji making: the moistened raw materials enter the continuous mixing tank, add sterile seed koji and mix evenly, and the evenly mixed materials are transported to the aseptic disc koji making machine through sterile pipelines, and the wind of the koji making machine Use after filtering through a filter to avoid contamination by bacteria. The koji making temperature is 25°C and the koji making time is 50 hours;

[0066] 4), salt water freezing: After the sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com