A kind of plasticized gypsum and preparation method thereof

A technology for dissolving gypsum and gypsum, applied in the field of plasticizing gypsum and its preparation, can solve problems such as poor durability and poor adhesion performance, and achieve the effects of convenient operation, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

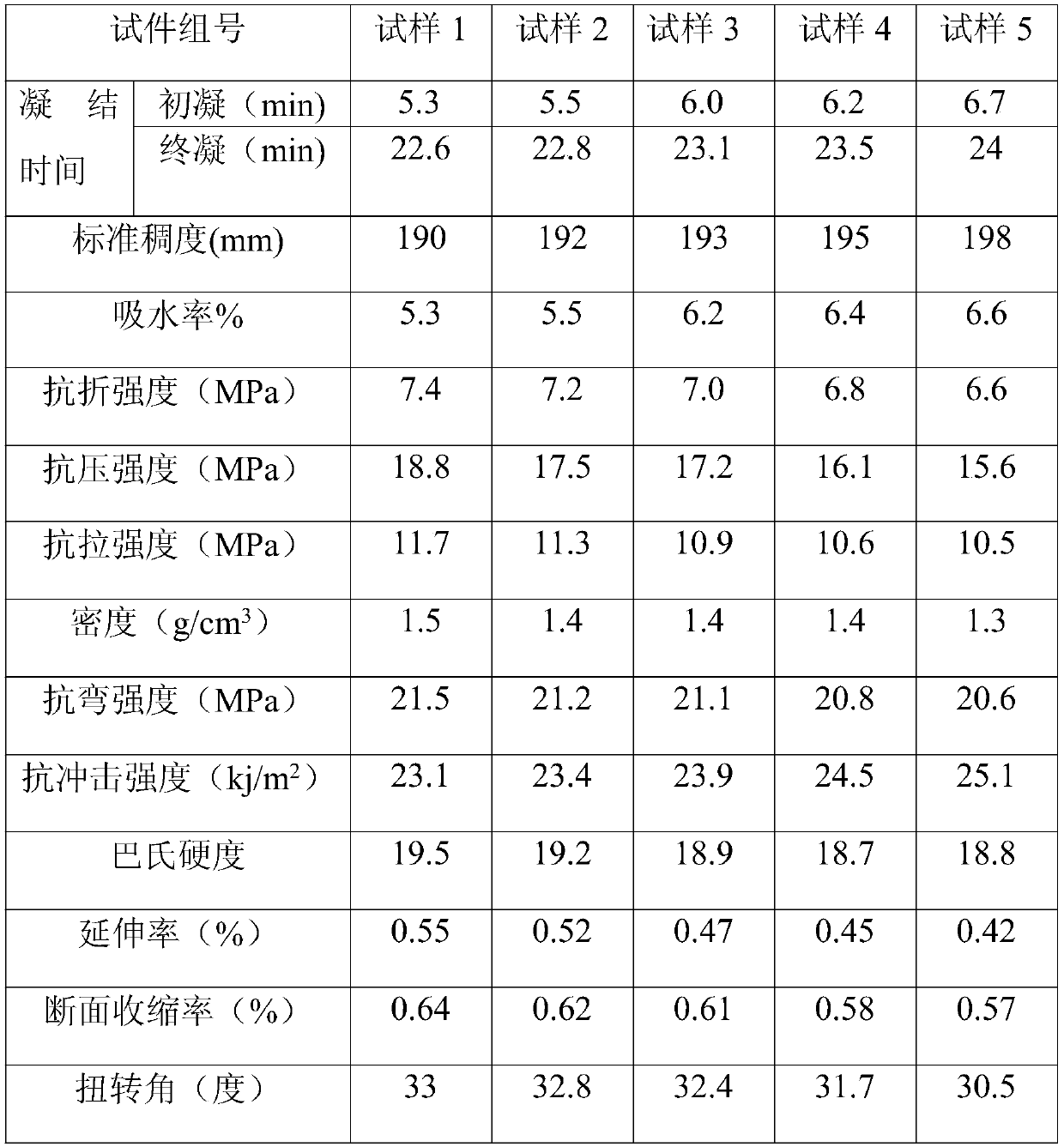

[0029] 1. See Table 1 for the materials and proportions of plasticized gypsum.

[0030] Table 1

[0031] material name

Sample 1

Sample 2

Sample 3

Sample 4

Sample 5

Gypsum powder (100%)

1000

1000

1000

1000

1000

Water (30-35%)

300

310

320

330

340

Sodium trimethylphosphate (0.1-0.15%)

1

1.1

1.2

1.3

1.4

CaO (3-3.5%)

30

31

32

33

34

White cement (1-1.5%)

10

11

12

13

14

ASH (5-6%)

50

51

52

53

54

[0032] Note: The mass of additives in the table is based on the mass of gypsum powder, unit (g).

[0033] 2. The gypsum powder mentioned in the table is alpha gypsum powder;

[0034] Described water is pure water;

[0035] The sodium trimethylphosphate is a kind of phosphate;

[0036] The CaO is an inorganic compound;

[0037] The white cement is a calcium silicate inorganic compound;

[0038] The ASH is vinyl acetate-ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com