Electric control device for online automatically controlling forging die temperature and control method thereof

An electronic control device and forging die technology, applied in the field of forging, can solve the problems affecting the quality of forgings, the early failure of forging die, and the lack of temperature measuring device for forging die, etc., to save labor costs, avoid liquid accumulation, and shorten the debugging period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0041] In order to achieve the purpose of automatically controlling the temperature of the forging die on-line, the present invention provides a control device and a control method for automatically controlling the temperature of the forging die on-line, so as to realize the on-line automatic control of the temperature of the forging die.

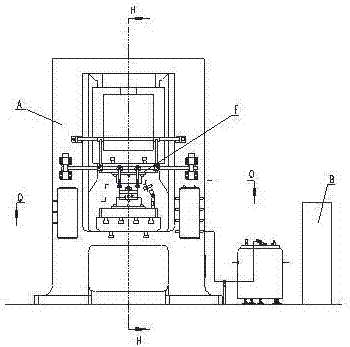

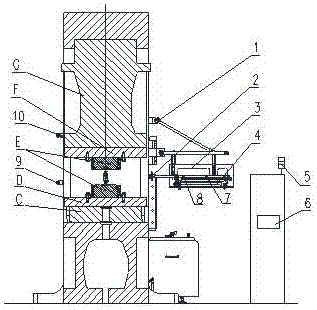

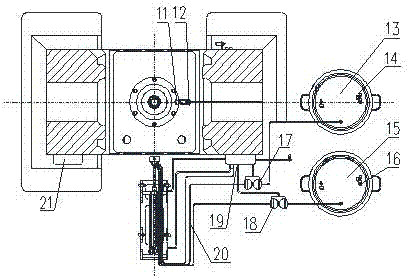

[0042] Such as Figure 1~7 Shown: an electronic control device for online automatic control of forging die temperature, including: PLC programmable controller 6, operation panel 21, man-machine interface 22, status indication unit 5, pneumatic electric control unit 23, chain control unit 24, Analog signal unit 25, liquid level detection unit 26, positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com