Beryllium-free molten salt reactor core using beryllium oxide for moderating

The technology of beryllium oxide and molten salt reactor is applied in the core design of molten salt reactor and the field of molten salt reactor core, which can solve the difficulty of increasing radioactive waste treatment, unsatisfactory radiation resistance performance, low graphite hardness and strength, etc. problems, to achieve the effects of high fuel salt solubility, improved structural mechanics and radiation resistance, and high fuel breeding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

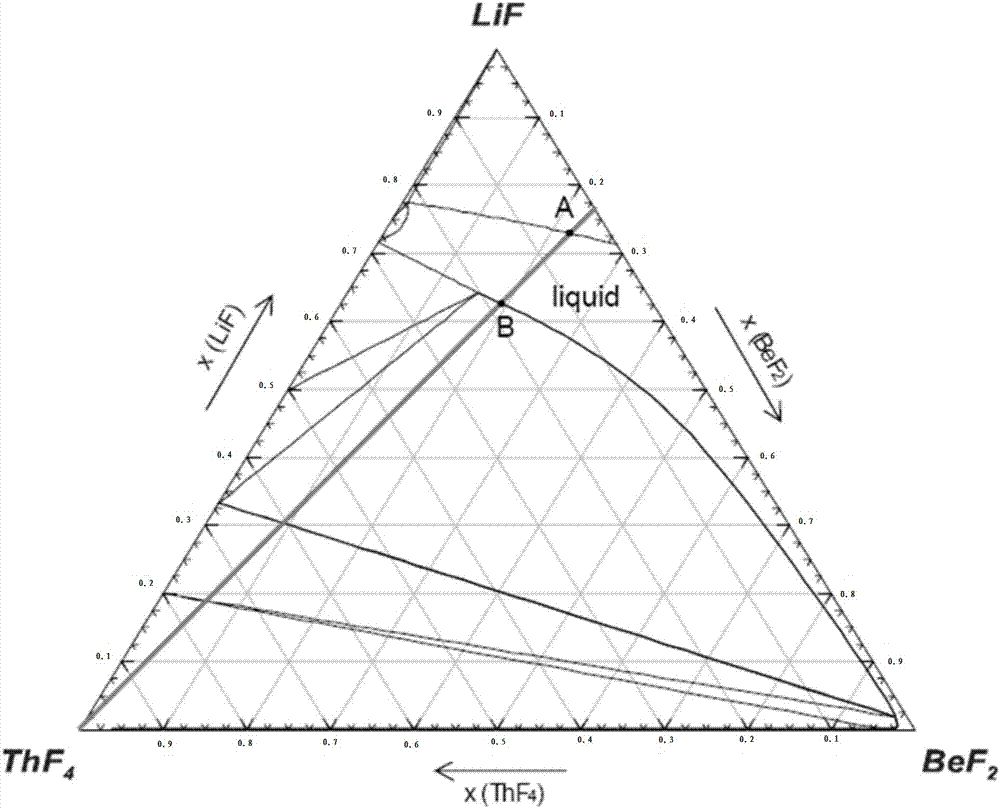

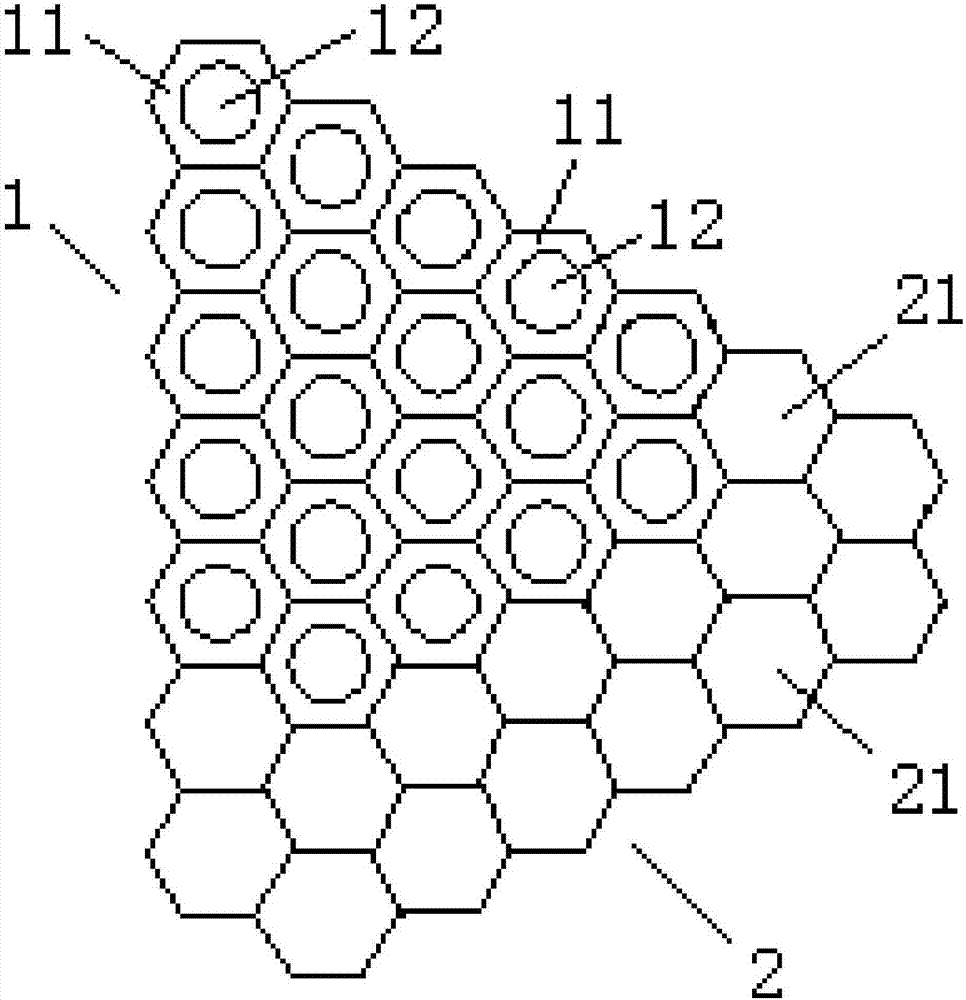

[0038] Such as figure 1 Shown is the molten salt reactor core moderated by beryllium-free molten salt beryllium oxide. The molten salt reactor core moderated by beryllium oxide-free molten salt includes a fuel grid 1 and a reflection layer grid 2 . The reflective layer grid 2 is arranged outside the fuel grid 1 and surrounds the fuel grid 1 . Fuel grid 1 uses beryllium oxide as moderator.

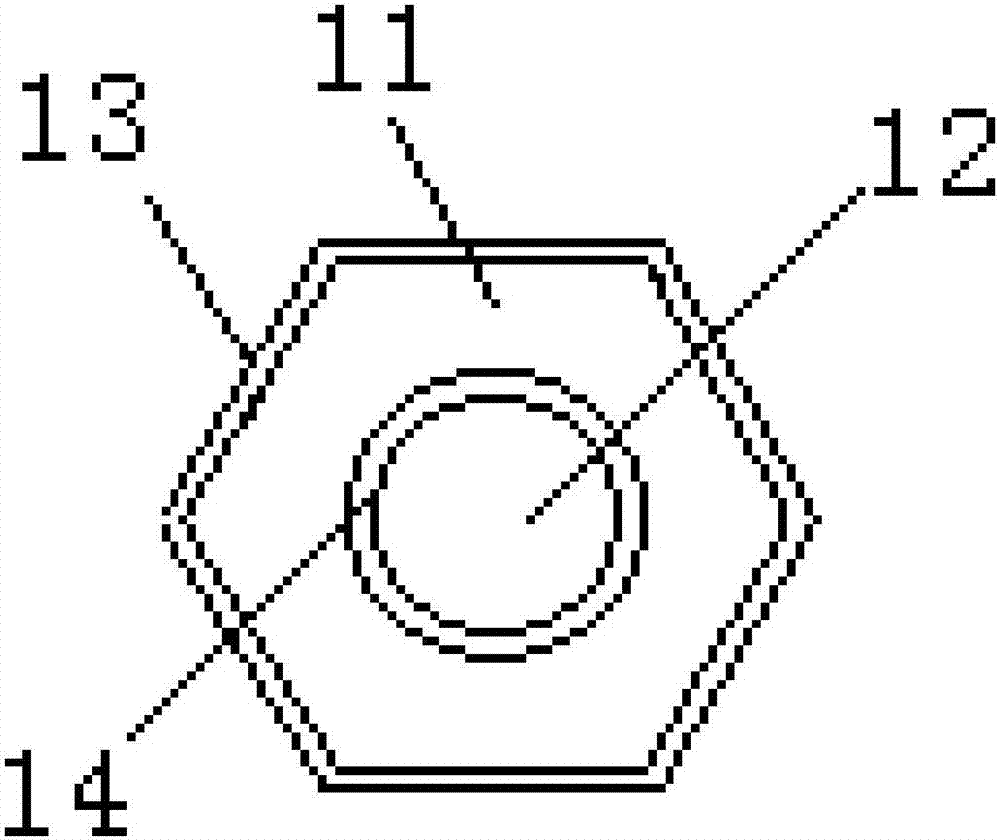

[0039] Such as figure 2 As shown, preferably, the fuel grid 1 includes a plurality of first cladding shells 13, and the first cladding shells 13 are cylinders. Multiple first cladding shells 13 are arranged in sequence along the radial direction of the first cladding shells. Each first enclosure 13 is provided with a second enclosure 14 . There is a gap between the first casing 13 and the second casing 14 . The space between the first shell 13 and the second shell 14 is filled with moderator 11 . The second cladding 14 is provided with a fuel channel 12 . The fuel flow channel 12 e...

Embodiment 2

[0059] Such as Figure 7-9 As shown, the difference from Embodiment 1 is that the fuel grid 1 of the core of this embodiment includes a plurality of third claddings 15 . The third shell 15 is a cylinder. A plurality of third casings 15 are arranged in sequence along the radial direction of the third casing and are spaced apart from each other. Moderator 11 is filled in the third shell 15 . The third cladding 15 is made of silicon carbide or carbon / carbon composite material. The space between each third cladding 15 is the fuel flow channel 12 . Each of the third includes 15 is arranged in an array or in a regular hexagon, and the six corners and the center of the regular hexagon are all distributed with third shells.

[0060] Each fuel channel 12 of the core 01 in this embodiment is located outside each third cladding 15 and communicates with each other. The fuel passages 12 communicate with each other, allowing the molten salts to mix with each other, which is beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com