Multi-cell direct-connection winding battery

A multi-unit, cell technology, applied in the construction of secondary batteries, lead-acid batteries, lead-acid batteries, etc., can solve the problems of easy deformation of the battery structure, environmental pollution, and increased internal resistance of the battery, to ensure battery consistency and battery life, avoid inconsistent internal reactions, avoid inconsistent effects of self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

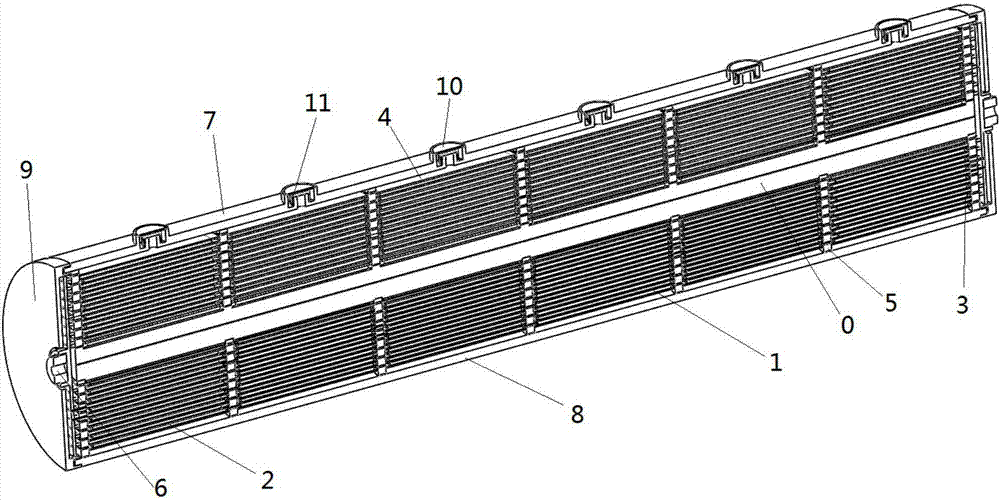

[0044] Please refer to figure 1 , the present invention proposes a multi-cell direct-connected winding battery, which includes a battery winding core, a winding battery shaft core 0, a number of insulating strips 5, a battery upper casing 7, a battery lower casing 8, and two round casting terminals 6 and two circular end caps 9, specifically described below.

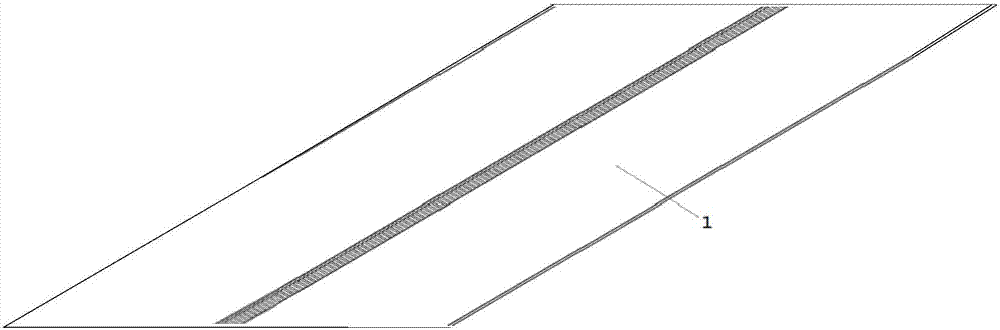

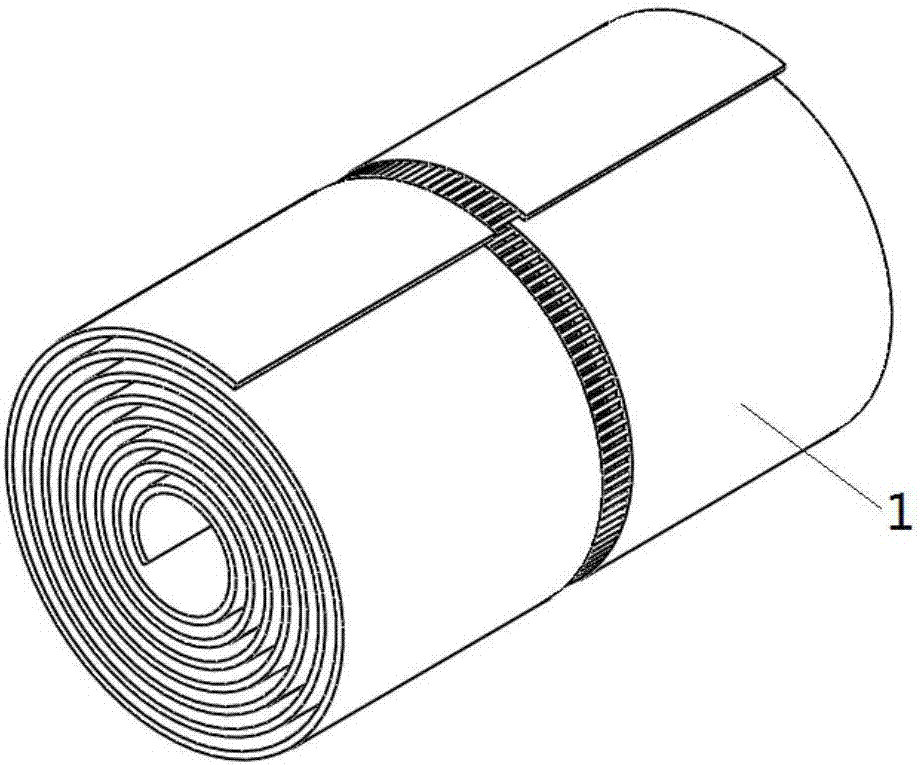

[0045] The battery core includes several bipolar wound plates 1 , positive terminal wound plates 2 , negative terminal wound plates 3 and a separator 4 .

[0046] Please refer to figure 2, half of the bipolar winding plate is coated with a positive active material as a positive plate, and the other half is coated with a negative active material as a negative plate, leaving a space in the middle that is not coated with positive and negative active materials for each unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com