Centrifugal flue gas desulfurization and denitration dedusting tower

A technology of desulfurization, denitrification, and dust removal tower, which is applied in the fields of environmental protection and resource recycling, and can solve problems such as impact effects, secondary pollution, and uneven spraying, and achieve the effects of simple and convenient maintenance, reduced operating costs, and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

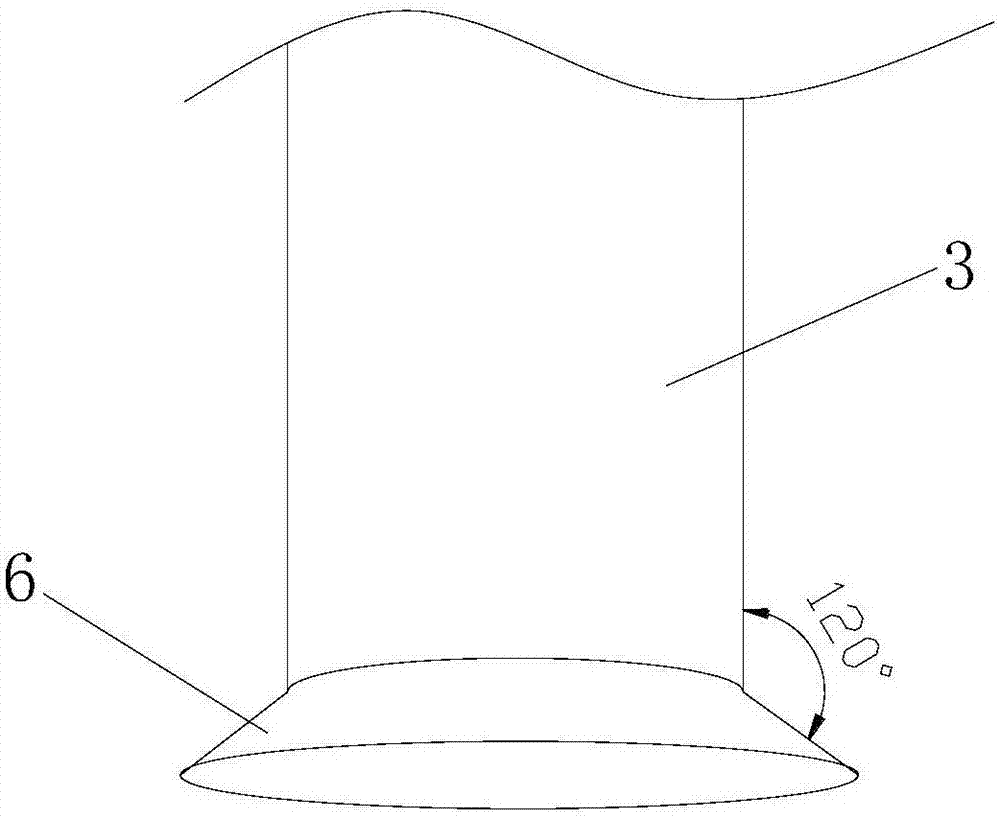

[0031] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0032] like Figure 1-5 Shown is a preferred embodiment of the invention.

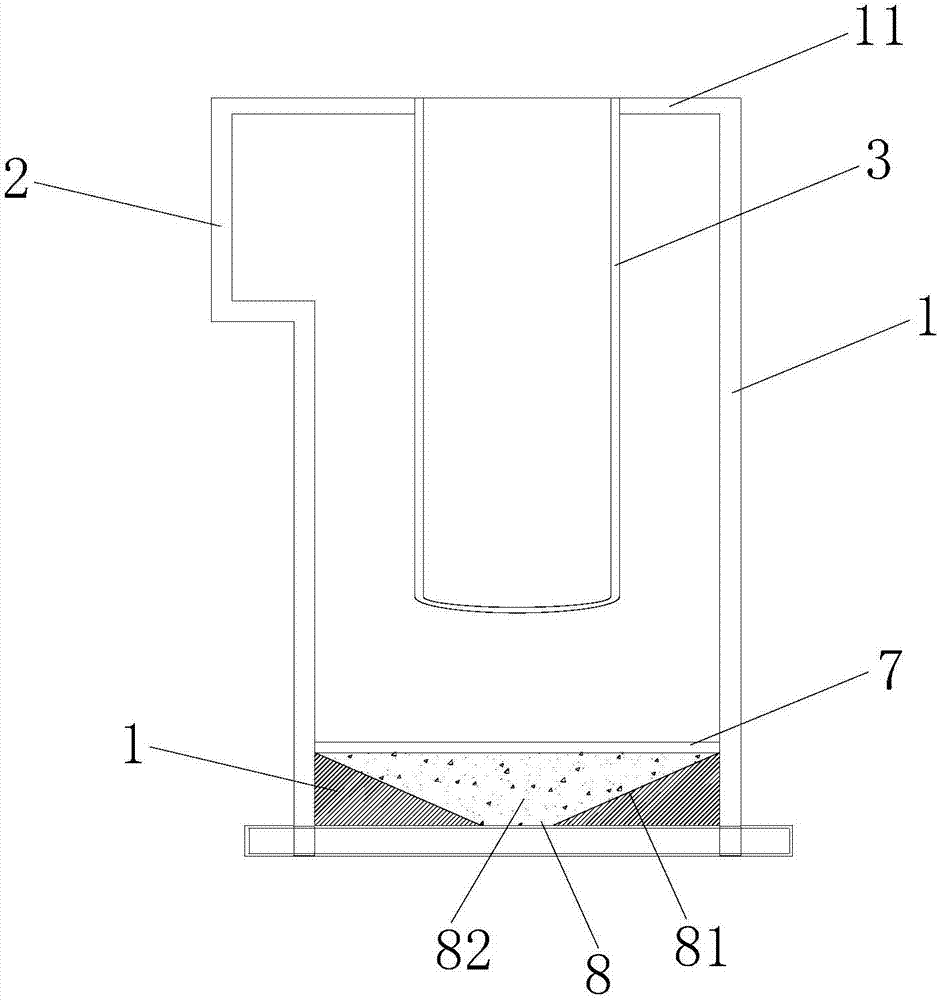

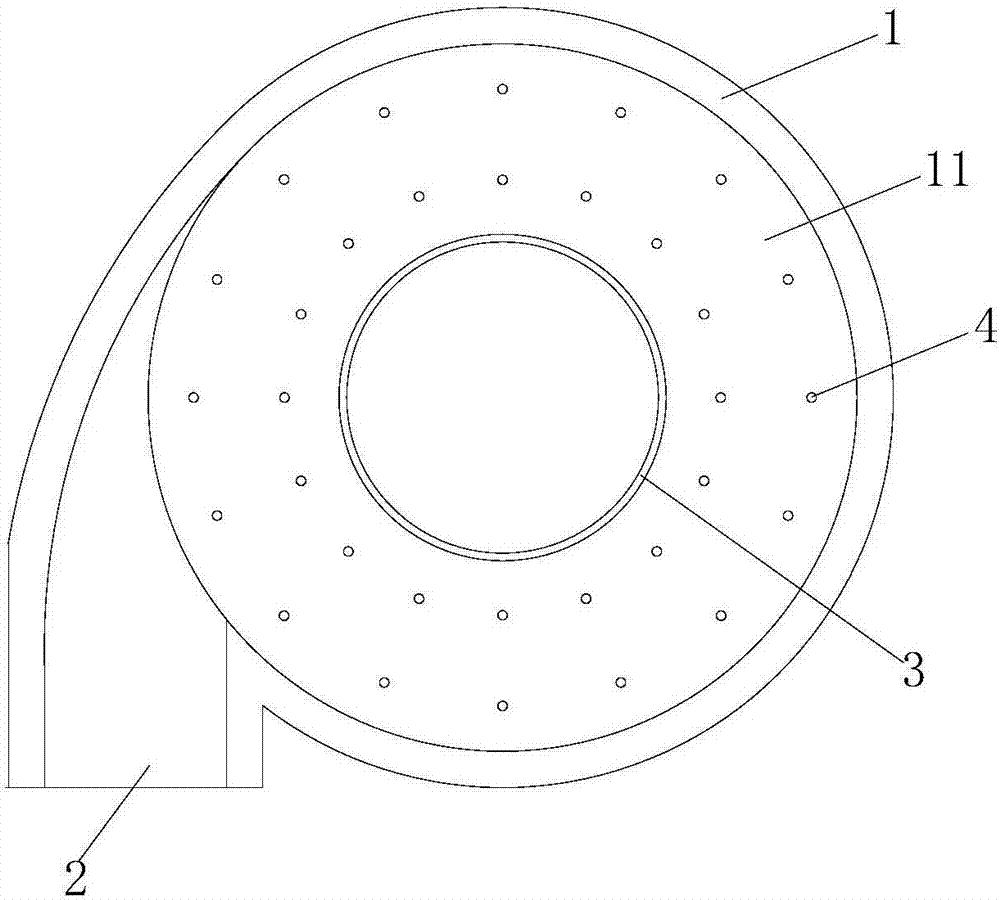

[0033] The centrifugal flue gas desulfurization, denitrification and dedusting tower of this embodiment includes:

[0034] The outer tower body 1 is cylindrical, and the tower chamber of the outer tower body 1 is a flue gas desulfurization, denitrification, and dust removal treatment area, and the bottom of the outer tower body 1 has a water outlet;

[0035] The flue gas input pipe 2, as the intake pipe of the flue gas in the outer tower body 1, is arranged on the tower top side wall of the outer tower body 1 and communicates with the tower cavity. There is an included angle of 45° between them, so that after the flue gas enters the tower cavity, it is transported against the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com