High-flow single-stage double-suction centrifugal slag flushing pump

A single-stage, double-suction, high-flow technology is applied to radial flow pumps, parts of pumping devices for elastic fluids, pumps, etc., which can solve problems such as small flow, unclean waste residue flushing, and large volume, and achieve Effect of increasing flow resistance, not easy to pollute the environment, wide temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

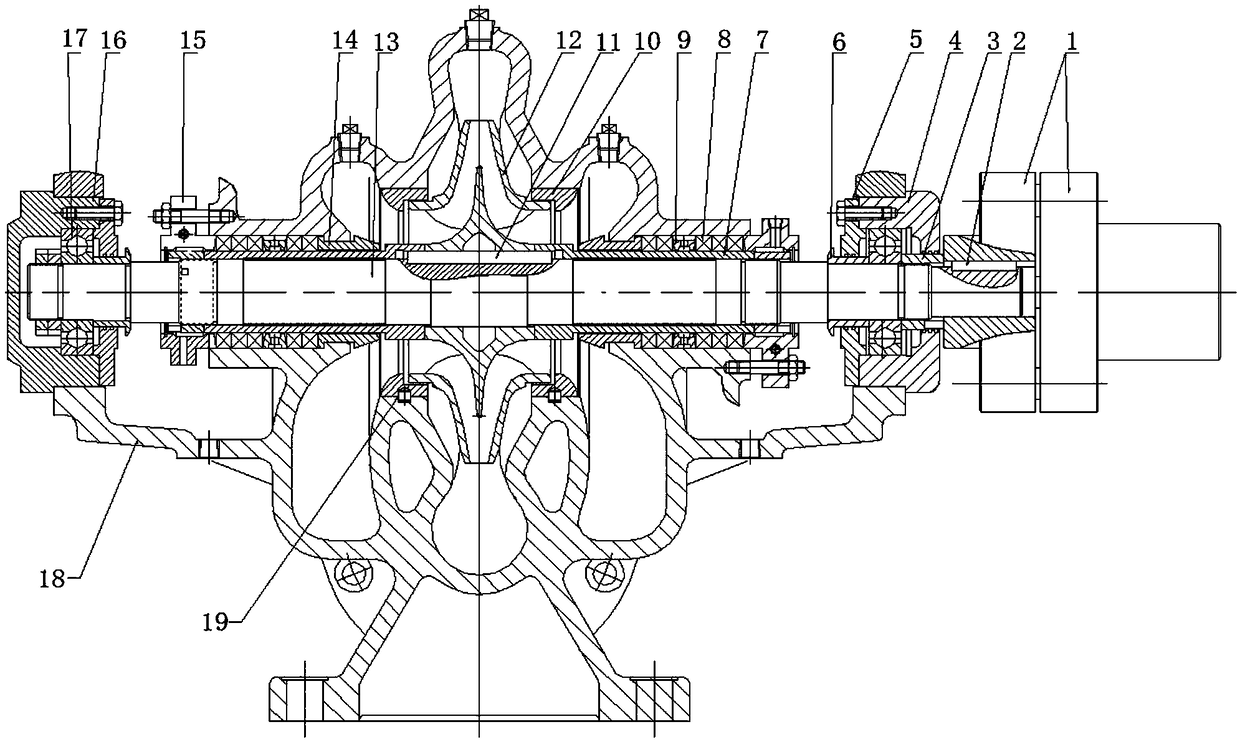

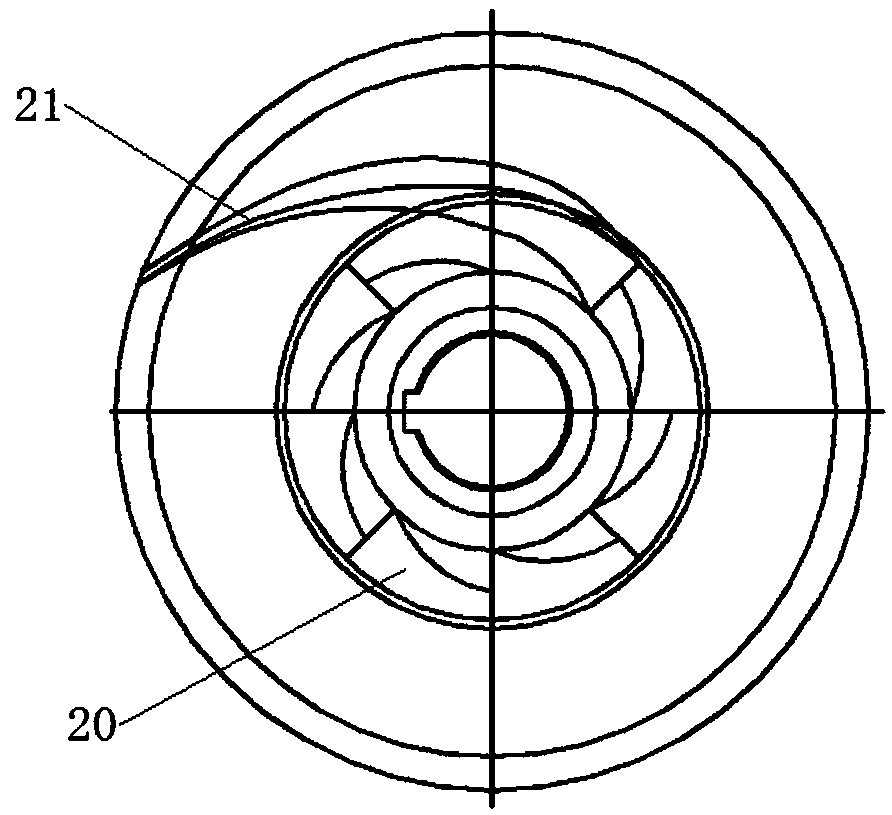

[0023] The present invention is a large-flow single-stage double-suction centrifugal slag flushing pump, the structure of which is as follows: figure 1 and figure 2 As shown, it includes an impeller 12, a pump shaft 13, and a pump casing 18. The pump shaft 13 passes through both sides of the pump casing 18. The impeller 12 is located in the pump casing 18 and is sleeved on the pump shaft 13 through the impeller key 11. The pump casing 18 It is a double volute structure, and the impeller 12 is provided with eight impeller blades 20 arranged symmetrically in the center, and a pointed impeller water outlet 21 is arranged between the two impeller blades 20 .

[0024] A shaft sleeve 7 is provided at the connection between the pump shaft 13 and the pump casing 18, and the outer circumference of the shaft sleeve 7 is sealed by an oil-stained asbes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com