Equipment for preparing metal clad plate and preparation method thereof

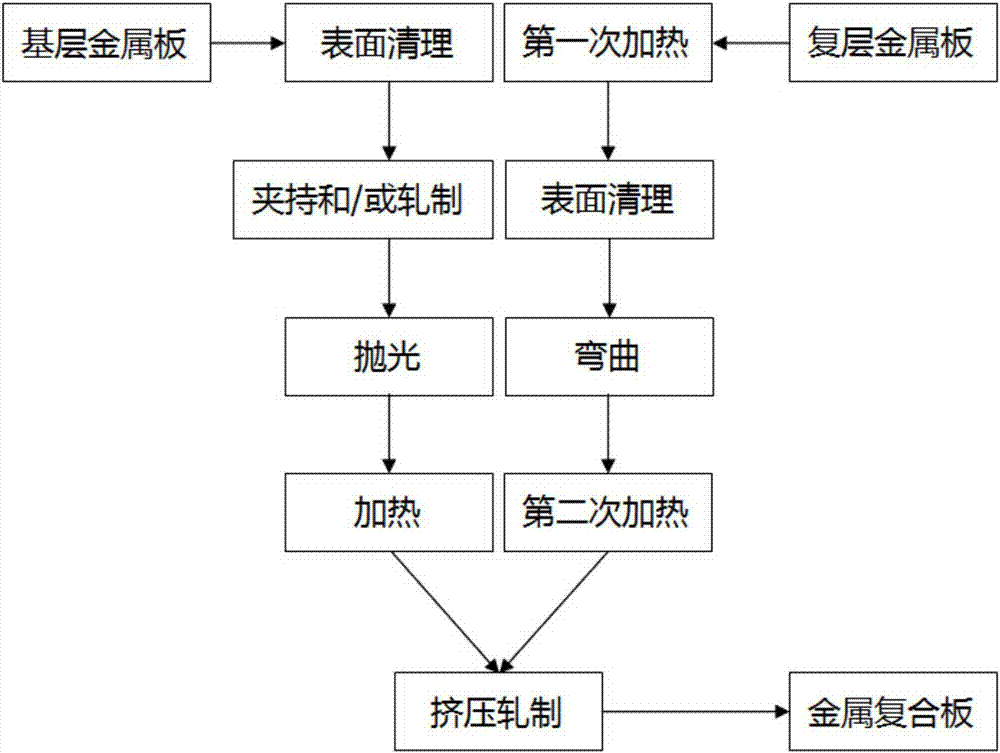

一种金属复合板、金属板的技术,应用在金属加工设备、金属轧制、金属轧制等方向,能够解决制约金属复合板发展、道次压下率要求较大、轧机要求高等问题,达到实现连续化生产、提高利用率、提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

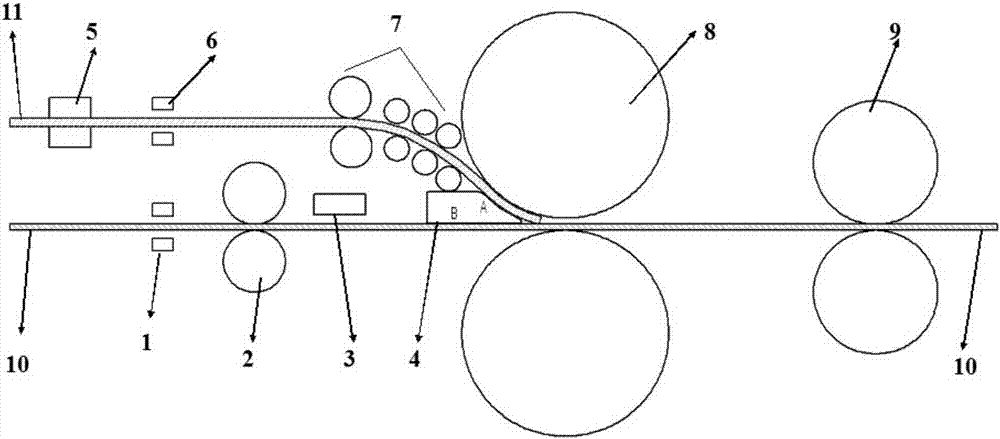

[0096] Preparation of a copper-steel metal composite board

[0097]In this embodiment, the base metal plate 10 is Q235 carbon structural steel with a thickness of 11 mm, and the cladding metal plate 11 is copper with a thickness of 9 mm.

[0098] a treatment of the base metal plate:

[0099] a.1 The first cleaning device 1 mechanically cleans the base metal plate 10 to obtain the base metal plate 10 with the surface oxide layer removed;

[0100] a.2 The first rolling mill 2 clamps the base metal plate 10 from which the surface oxide layer has been removed and transports the base metal plate 10 horizontally to the polishing device 3 at a specified speed;

[0101] a.3 The polishing device 3 performs horizontal grinding and surface cleaning on the upper surface of the base metal plate 10 with a flat surface to obtain a polished base metal plate 10;

[0102] a.4 The polished base metal plate 10 is sent to the first heating device 4, and the composite surface of the base metal pl...

Embodiment 2

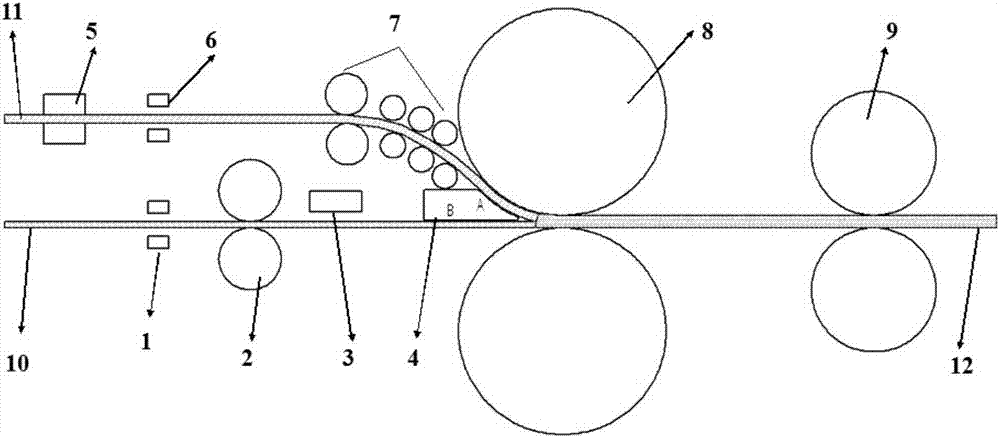

[0113] Preparation of a copper-stainless steel composite plate

[0114] In this embodiment, the base metal plate 10 is Q235 carbon structural steel with a thickness of 10 mm, and the cladding metal plate 11 is copper with a thickness of 9 mm.

[0115] a treatment of the base metal plate:

[0116] a.1 The first cleaning device 1 mechanically cleans the base metal plate 10 to obtain the base metal plate 10 with the surface oxide layer removed;

[0117] a.2 The first rolling mill 2 clamps the base metal plate 10 from which the surface oxide layer has been removed and transports the base metal plate 10 horizontally to the polishing device 3 at a specified speed;

[0118] a.3 The polishing device 3 performs horizontal grinding and surface cleaning on the upper surface of the base metal plate 10 with a flat surface to obtain a polished base metal plate 10;

[0119] a.4 The polished base metal plate 10 is sent to the first heating device 4, and the composite surface of the base met...

Embodiment 3

[0130] Preparation of a kind of aluminum-copper metal composite board

[0131] In this embodiment, the base metal plate 10 is copper with a thickness of 7 mm, and the cladding metal plate 11 is 1050 aluminum with a thickness of 5 mm.

[0132] a treatment of the base metal plate:

[0133] a.1 The first cleaning device 1 mechanically cleans the base metal plate 10 to obtain the base metal plate 10 with the surface oxide layer removed;

[0134] a.2 The first rolling mill 2 clamps the base metal plate 10 from which the surface oxide layer has been removed and transports the base metal plate 10 horizontally to the polishing device at a specified speed;

[0135] a.3 The polishing device 3 performs horizontal grinding and surface cleaning on the upper surface of the base metal plate 10 with a flat surface to obtain a polished base metal plate 10;

[0136] a.4 The polished base metal plate 10 is sent to the first heating device 4, and the composite surface of the base metal plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com