High-precision welding machine tool for steel plate

A welding machine tool, high-precision technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving accuracy, improving welding accuracy, and avoiding indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

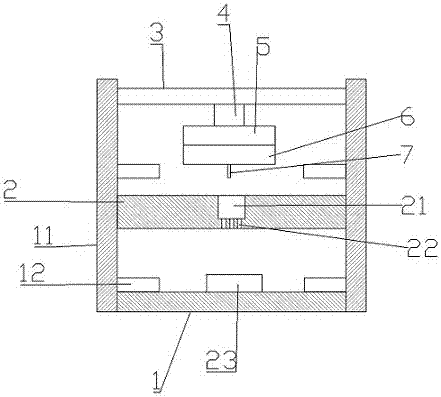

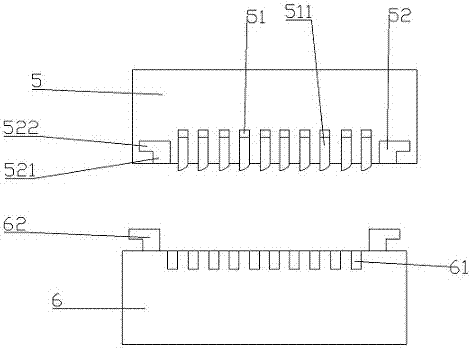

[0024] The reference signs in the drawings of the description include: machine bed 1, frame 11, electromagnet 12, workbench 2, through groove 21, through hole 22, negative pressure machine 23, spindle box 3, rotating shaft 4, angle adjustment disc 5. Mounting holes 51 , locking teeth 511 , fixing slots 52 , mounting parts 521 , limiting parts 522 , welding discs 6 , locking slots 61 , protrusions 62 , and welding torches 7 .

[0025] like figure 1 As shown, a high-precision welding machine tool for steel plates includes a machine bed 1, a frame 11 is provided on the left and right sides of the machine bed 1, and a workbench 2 is provided between the two frames 11. Workbench 2 is provided with through groove 21, and through groove 21 is perpendicular to the front surface of workbench 2, and the bottom of through groove 21 is provided with through hole 22, and the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com