Automatic control industrial kiln burning machine movement rack system

A burner and mobile rack technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as inability to evacuate in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

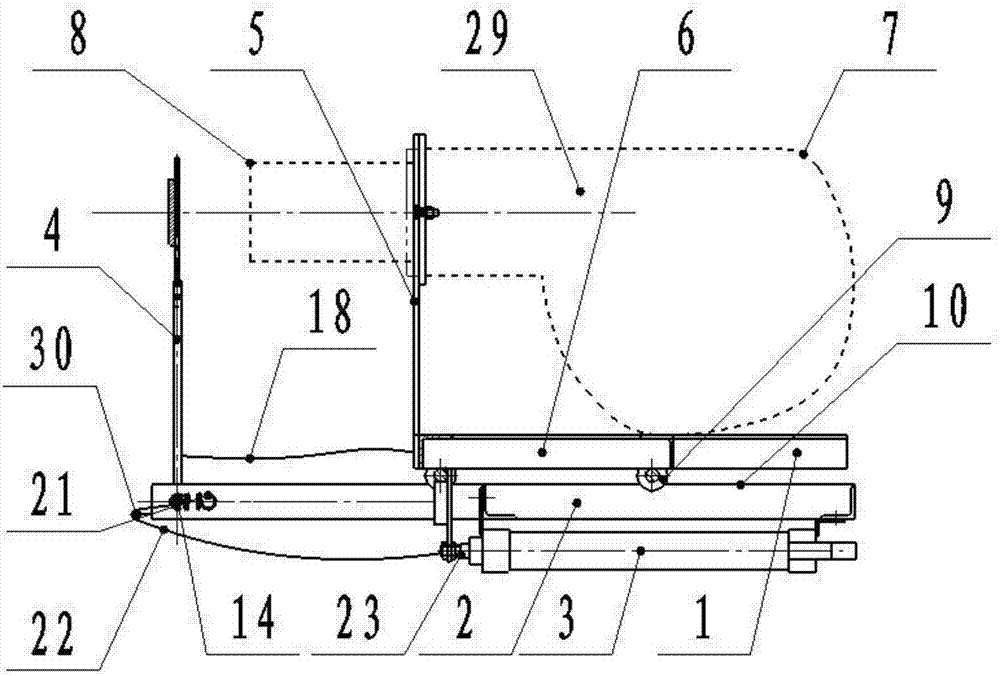

[0028] like Figure 1-5 As shown, an automatic control industrial kiln burner mobile rack system of the present invention includes a burner installation trolley 1, an underframe 2, a cylinder 3 and a blocking device 4, and the burner installation trolley 1 is provided with a stand 5 and a translation rack 6. The vertical frame 5 is vertically welded on the front end of the translation frame 6 to support the burner 8 of the burner 7. The bottom of the translation frame 6 is provided with a pulley 9, and the bottom frame 2 is provided with a guide rail 10 that matches the pulley 9. The cylinder 3 It is arranged on the bottom of the chassis 2 to push the burner installation trolley 1 and the burner 7 to move back and forth; the burner 7 generally includes a burner 8 and a fuselage 29 inserted into the furnace.

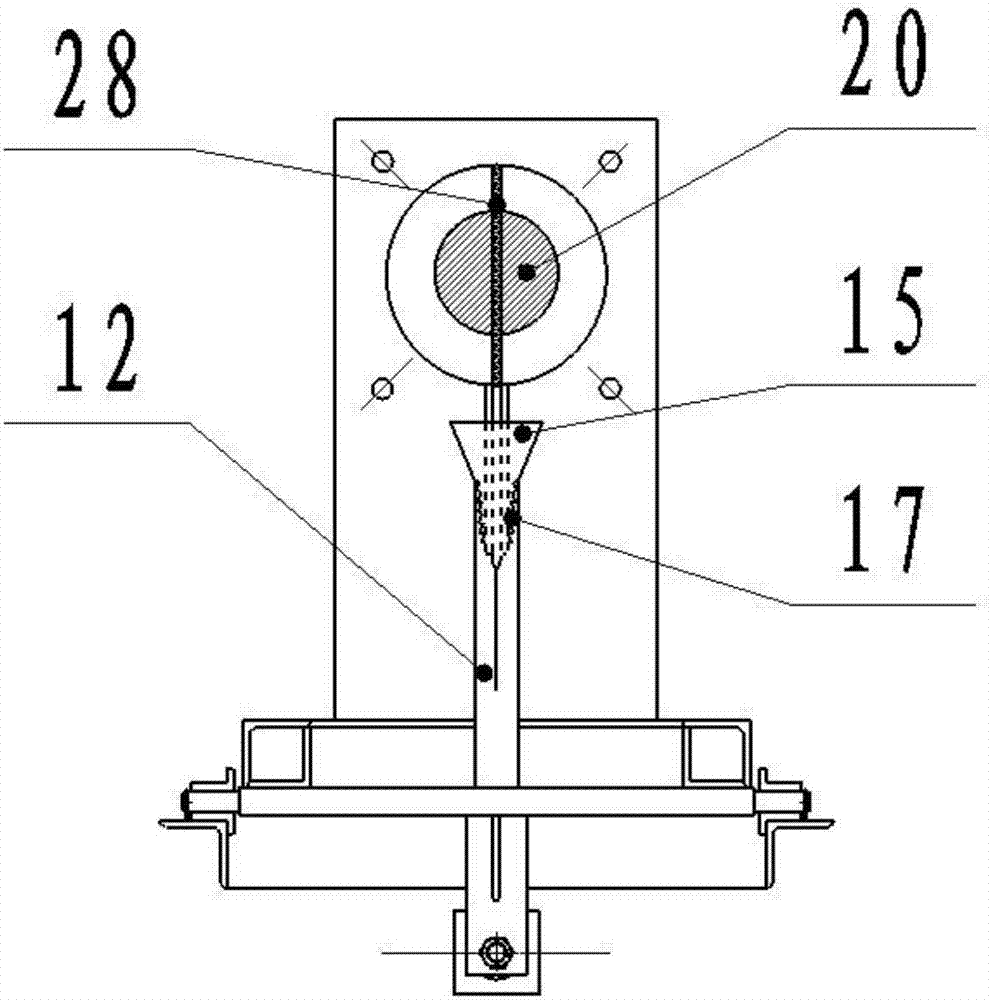

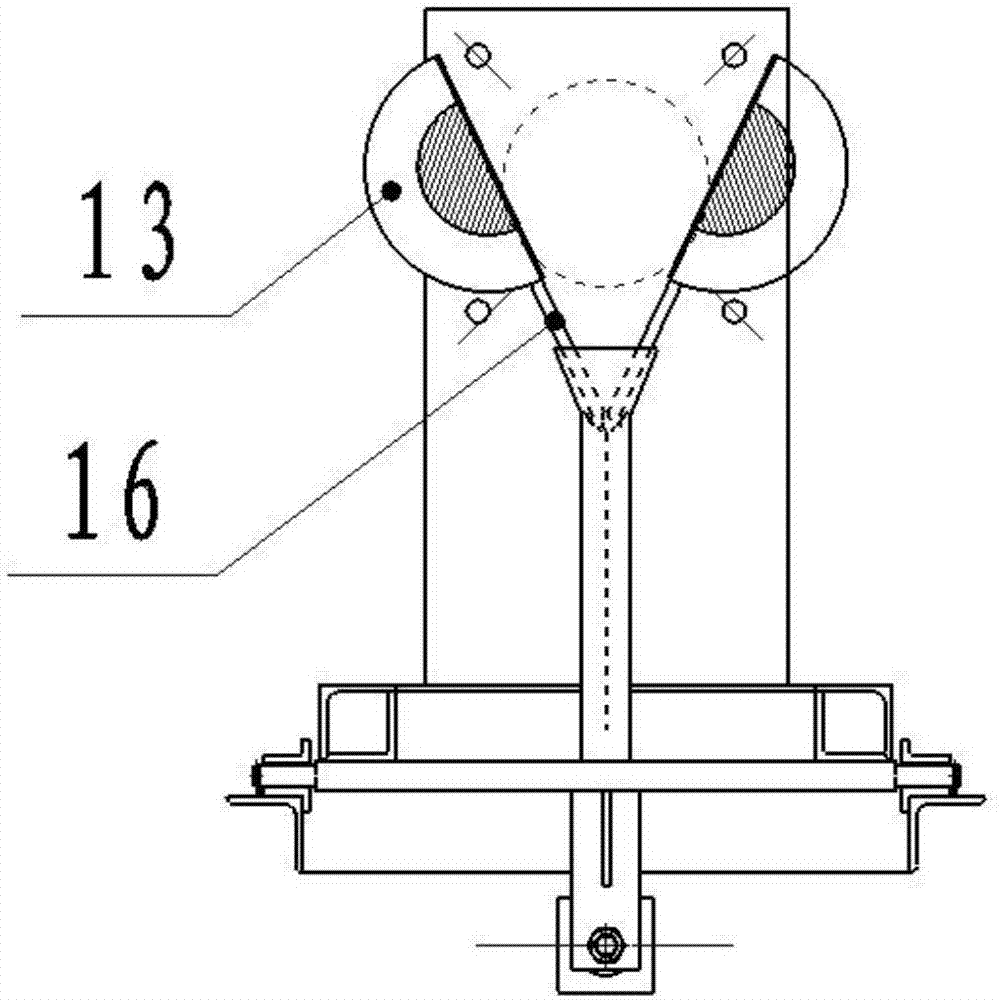

[0029] The front part of the chassis 2 is provided with a blocking device chute 11, and the blocking device 4 includes a moving guide cylinder 12 and a blocking semicircl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com