Detection test paper for content of micro-water in aviation fuel and preparation method of detection test paper

A technology for aviation fuel and test paper, which is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of difficulty in judging the failure of test paper, short validity period of test paper, and existence of use Risks and other issues, to achieve the effect of easy detection, easy judgment, and long maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O preparation detection test paper, concrete preparation method is as follows:

[0031] S1: Sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O was dried to constant weight respectively, and then mixed uniformly with a molar ratio of 1:1 to obtain a detection composition;

[0032] S2: Dry the white filter paper (dried in an oven at 80°C), and then in a nearly anhydrous infrared drying oven, use electrostatic powder spraying technology to evenly coat the detection composition on one side of the dried white filter paper , coating amount is 2mg / cm 2 , get test paper.

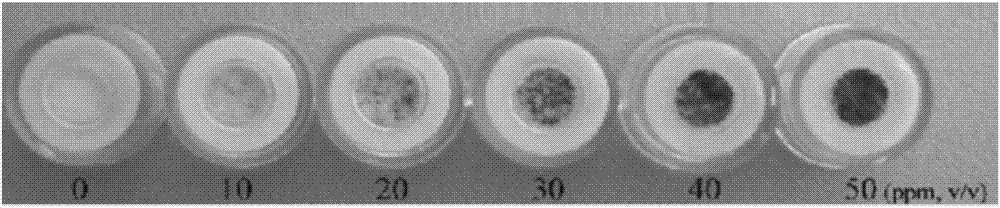

[0033] Effect detection: use the test paper to measure aviation fuel with different free water content, the results obtained are: yellow (0ppm), light yellow-green spots (10ppm), yellow-green spots (20ppm), green spots (30ppm), blue spots (40ppm), dark blue spots (50ppm); the specific results are as follo...

Embodiment 2

[0035] In this example, sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O, mixed with different molar ratios to prepare different groups of detection test papers, the specific preparation method is as follows:

[0036] S1: Sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O were dried to constant weight, and then mixed uniformly at molar ratios of 10:1, 7:1, 4:1, 1:1, 1:4, 1:7, 1:10 to obtain different groups of detection combinations thing;

[0037] S2: Dry the white filter paper (dried in an oven at 80°C), and then in a nearly anhydrous infrared drying oven, use electrostatic powder spraying technology to evenly coat different groups on one side of the dried white filter paper. For other detection compositions, the coating amount is 2mg / cm 2 , to obtain different groups of test papers.

[0038] Effect detection: use the different detection test papers prepared above to store, and measure the storage period (shelf life), and the specifi...

Embodiment 3

[0042] In this example, sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O, mixed with different molar ratios to prepare different groups of detection test papers, the specific preparation method is as follows:

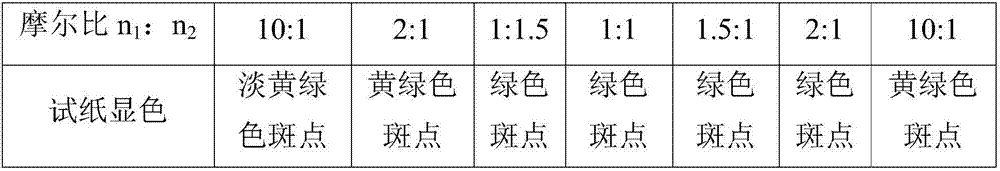

[0043] S1: Sodium ferrocyanide (Na 4 [Fe(CN) 6 ]·3H 2 O) and FeCl 3 ·6H 2 O were dried to constant weight, and then mixed uniformly at molar ratios of 10:1, 2:1, 1:1.5, 1:1, 1.5:1, 2:1, 1:10 to obtain different groups of detection combinations thing;

[0044] S2: Dry the white filter paper (dried in an oven at 80°C), and then in a nearly anhydrous infrared drying oven, use electrostatic powder spraying technology to evenly coat different groups on one side of the dried white filter paper. For other detection compositions, the coating amount is 2mg / cm 2 , to obtain different groups of test papers.

[0045] Effect test: Use the different test papers prepared above to test aviation fuel containing 30ppm free water, and compare the water color re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com