Self-driven optical excitation gas sensor

A gas sensor and gas sensor technology, applied in the direction of material resistance, can solve the problems of energy loss, inability to maintain continuous power consumption of heating elements, increase costs, etc., and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

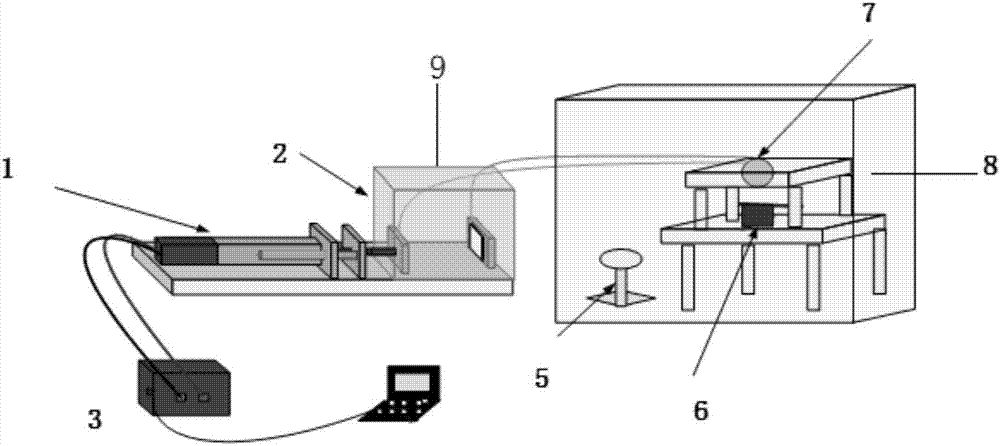

[0018] see figure 1 As shown, this embodiment provides a self-driven light-excited gas sensor, including a triboelectric nanogenerator, a packaging component, a light source, and a gas sensor. The triboelectric nanogenerator is electrified by friction, and the electric signal generated is used as an energy source, which is directly used for power supply of LED lamps, including friction materials, Faraday covers, electric motors, and drivers; the packaging assembly encapsulates the gas sensor and the light source In a sealed space, including an air inlet and a heater; the light source is a single light source with a fixed wavelength range; the gas sensor is a semiconductor gas sensitive material gas sensor, and the thickness of the sensitive material coating is 0.4-0.5 mm.

[0019] Wherein, the friction material component of the friction nano generator is titanium dioxide nano array.

[0020] The titanium dioxide nano-array is prepared by hydrothermal method and high-temperat...

Embodiment 2

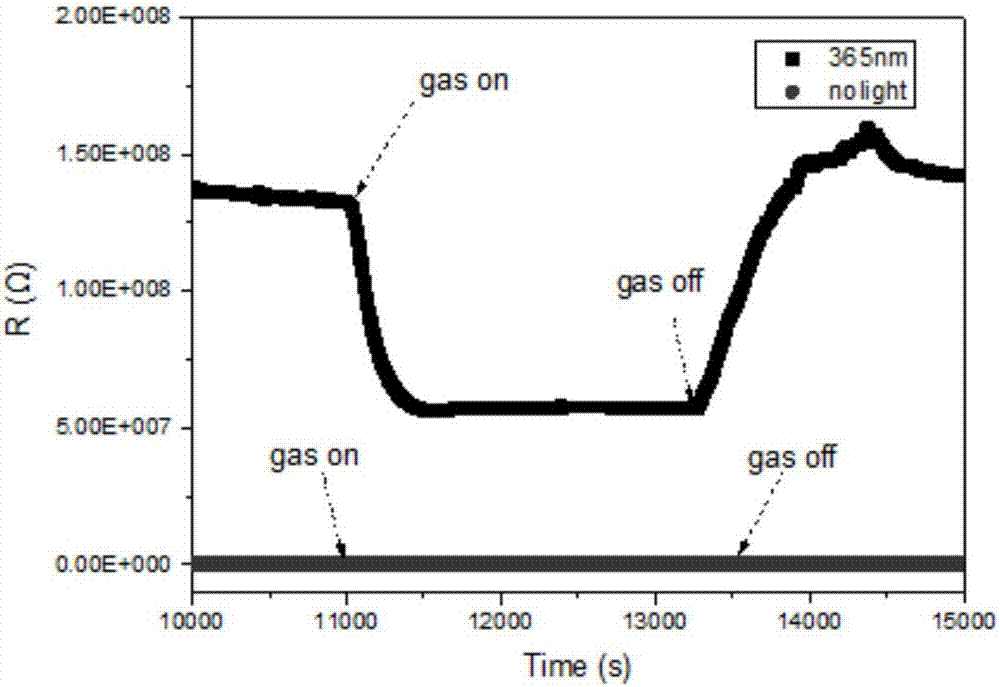

[0031] The difference between the technical solution of this embodiment and Embodiment 1 is that the material of the semiconductor gas sensor and the test gas are different. This embodiment only describes the different parts, and the same parts will not be repeated. The material of the semiconductor gas sensor selected in this embodiment is WS 2 Nanomaterials, test gas is 10ppm NH 3 . image 3 WS under room temperature conditions with 365-400nm light excitation and no light conditions 2 Gas sensor for 10ppm NH 3 Comparison chart of the resistance change curve.

Embodiment 3

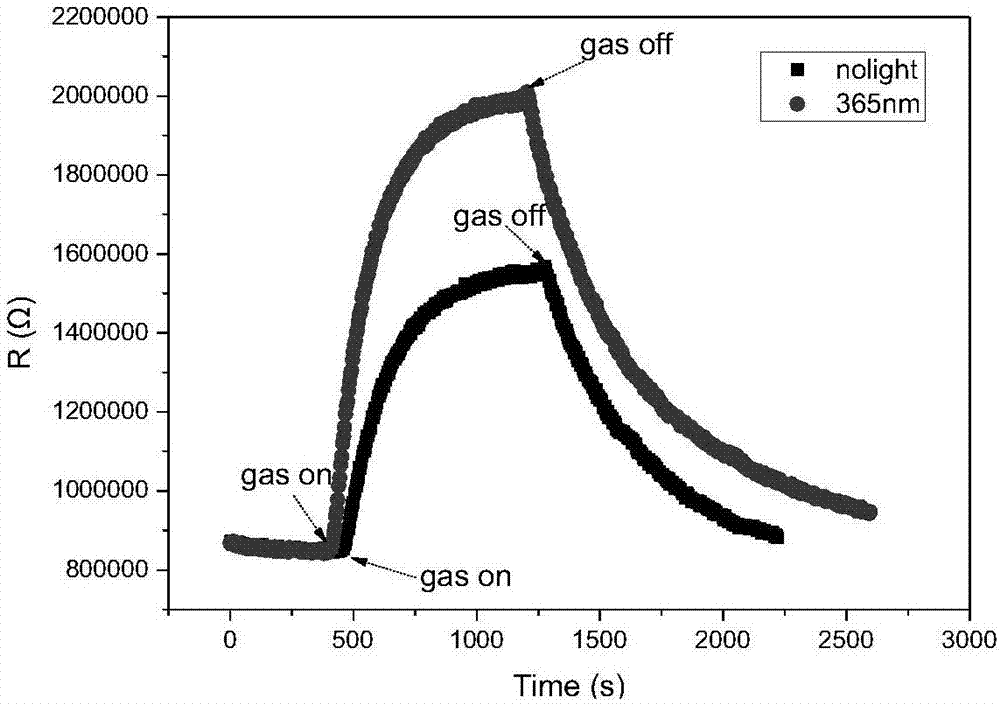

[0033] The difference between the technical solution of this embodiment and Embodiment 2 is that the parameter setting of the driver of the friction generator and the light source test selected are different. This embodiment only describes the different parts, and the same parts will not be repeated. The light source selected in this embodiment is a bead-type LED light source with a wavelength of 940nm and a rated power of 24mW. Figure 4 WS under room temperature conditions with a wavelength of 940nm light excitation and under no light conditions 2 Gas sensor for 10ppm NH 3 Comparison chart of the resistance change curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com