Pencil material granulator

A granulator and pencil technology, applied in the direction of mold extrusion granulation, fuel, waste fuel, etc., can solve the problems of low melting point of paraffin, short service life of bearings, low processing efficiency, etc., and achieve the effect of reducing high temperature and easy solidification and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific implementation manners thereof will be described in detail below with reference to the accompanying drawings:

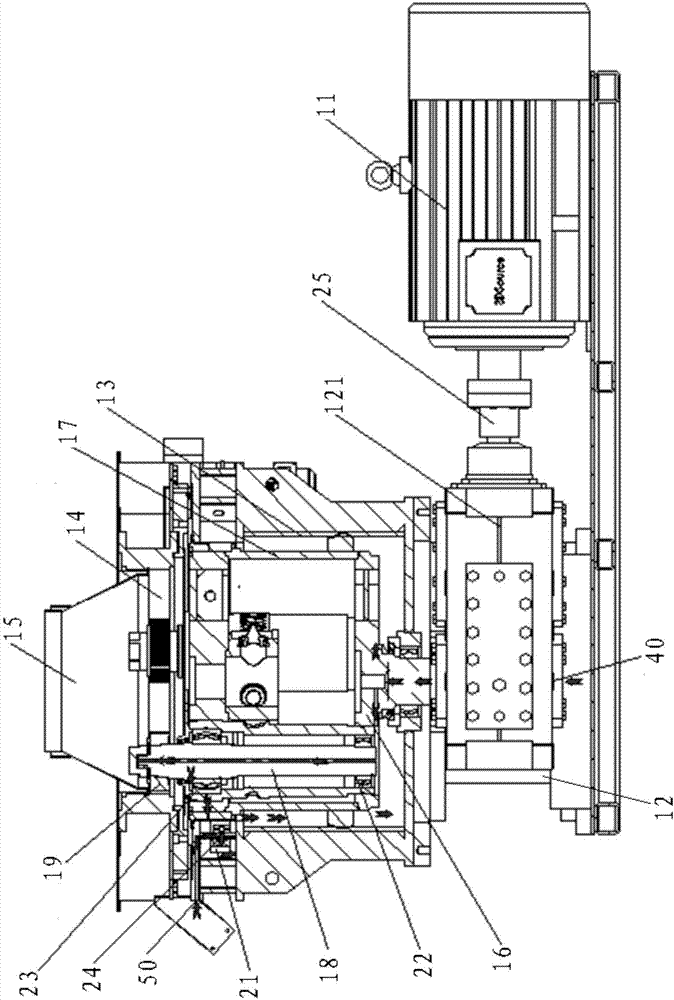

[0028] See figure 1 , The best embodiment of the present invention, a pencil pelletizing machine, including a motor 11, a reduction box 12, a box 13, a pelletizing chamber 14, a feed port 15, a transmission plate 16, a planet carrier 17, and a roller shaft 18 , The pressure roller shell 19, the supporting wheel 21, the first bearing 22, the second bearing 23 and the third bearing 24.

[0029] The reduction box 12 is provided with a reducer 121; the motor 11 is connected to the reducer 121 through a coupling 25; the bottom of the reduction box 12 is provided with an oil inlet; the box body 13 is arranged above the reduction box 12; the feed inlet 15 is arranged At the top of the box body 13; the granulating chamber 14 is arranged in the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com