Steel bar truss sandwich prefabricated floor slab

A steel truss and sandwich technology, which is applied to floors, building components, buildings, etc., can solve the problems of easy occurrence of slab seams, poor integrity, and no reduction in structural weight, so as to achieve a beautiful overall slab surface, solve the problem of slab seams, and improve the The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

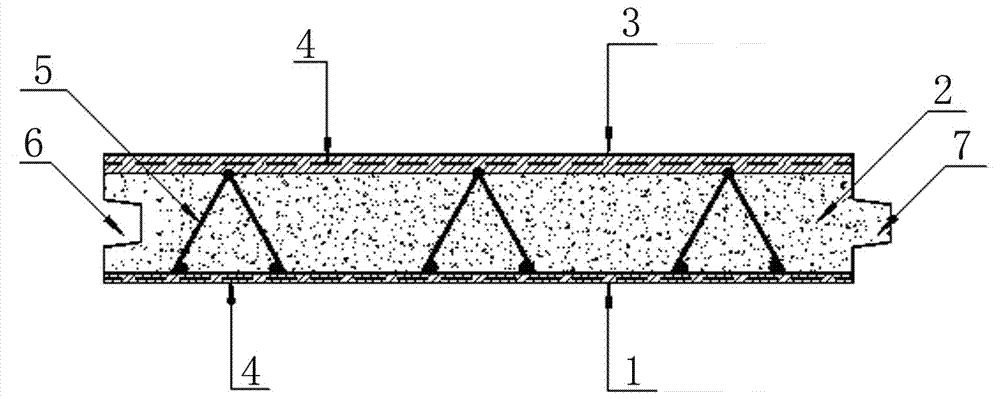

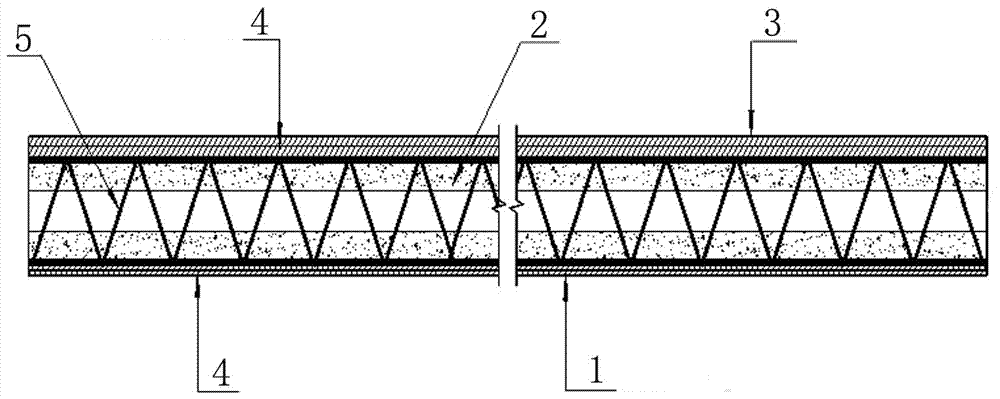

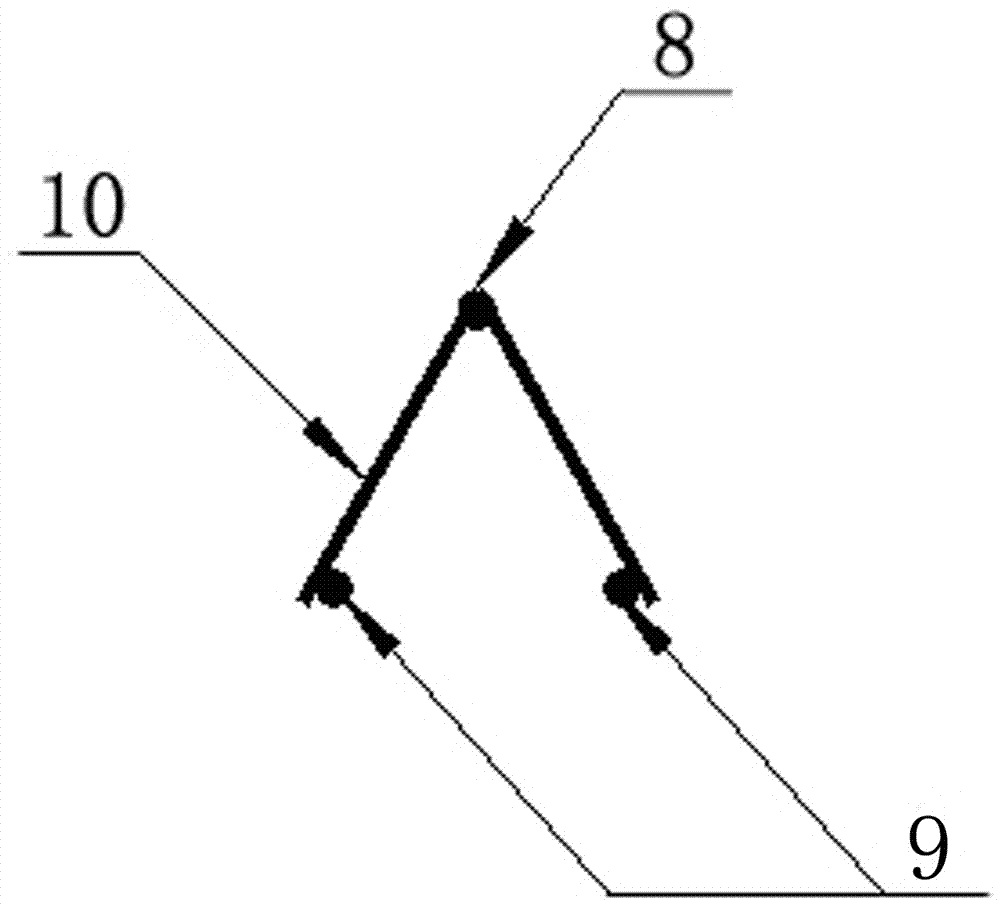

[0031] Such as Figure 1 to Figure 4As shown, the reinforced truss sandwich prefabricated floor slab of the present invention is a layered structure sandwich panel composed of a lower hard material layer 1, a cement polystyrene sandwich layer 2 and an upper hard material layer 3 stacked from bottom to top ; In the lower hard material layer 1 and the upper hard material layer 3, a steel wire mesh sheet 4 is evenly laid (the purpose is to prevent cracking and strengthen the surface layer rigidity), and the cement polystyrene sandwich layer 2 is wrapped with Several groups of triangular steel trusses 5 extending in the longitudinal direction are provided with longitudinally extending and mutually matching tenons 7 and grooves 6 on the left and right sides of the cement polystyrene sandwich layer 2 (which can be realized during on-site assembly) rapid positioning and fast splicing of two adjacent sandwich panels, and the sealing effect is good after being treated with cement-based...

Embodiment 2

[0039] The difference between this embodiment and the first embodiment is that the cross-sectional shape of the tenon 7 and the groove 6 is semi-arc (when two adjacent sandwich panels are assembled, the tenon 7 and the groove 6 are easy to assemble, It is convenient for quick positioning, and the corresponding arc-shaped mold is easy to process).

[0040] Concrete use process of the present invention is:

[0041] The steel bar truss sandwich prefabricated floor slab of the present invention can be used as an indoor floor slab, and can also be used as an inner partition board or an outer wall board. The operation during use is very simple. Take the floor as an example: First, transport and place several sandwich panels of the present invention to the corresponding positions to be installed, so that the tenon 7, The grooves 6 are mutually clamped and spliced; then, after the floor is positioned, the steel wire mesh sheet 4 and the lower main reinforcement 9 in the lower hard ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com