Triphasic system for direct conversion of sugars to furandicarboxylic acid

A furandicarboxylic acid, conversion technology, applied in the direction of organic chemistry, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

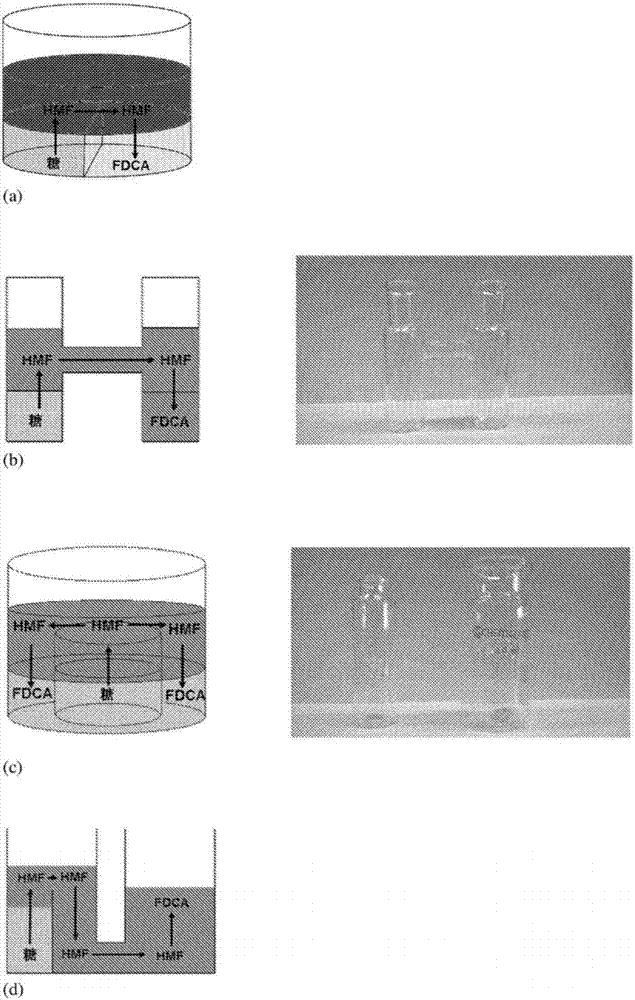

[0031] An exemplary, non-limiting embodiment of the one-pot process will now be disclosed.

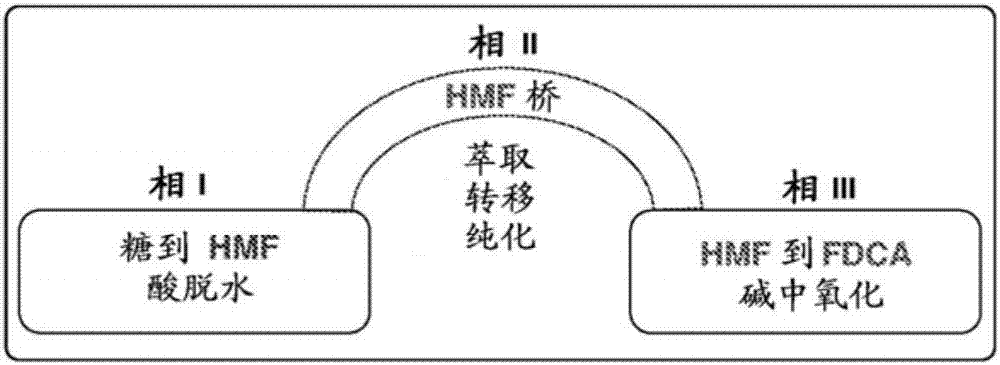

[0032] Provided is a one-pot process for producing furandicarboxylic acid from carbohydrates, the process comprising:

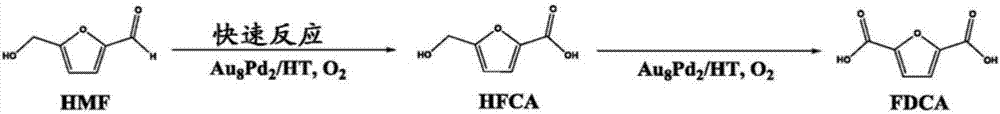

[0033] a) reacting said carbohydrate via a dehydration reaction to produce an intermediate in a first solvent phase; b) contacting said first solvent phase at a first contact zone with a second solvent phase at a first contact zone; c) extracting the intermediate into the second solvent phase; d) contacting the second solvent phase directly with a third solvent phase at a different contact zone; and e) oxidizing the intermediate to The furandicarboxylic acid is produced in the third solvent phase.

[0034]In step a), said carbohydrate may be a carbohydrate capable of being dehydrated to said intermediate. The carbohydrates may preferably be selected from cellulose, fructose, glucose, any other sugar, or isomers thereof, such as D-glucose or D-fructose. Fructose and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com