Urethane adhesive for laminated sheets

A technology for laminating sheets and adhesives, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as strict hydrolysis resistance requirements, and achieve low-temperature adhesive properties. Excellent effect of excellent long-term hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] As shown in Table 2, 93.5 g of (A1) polymer 1 [187.0 g of polymer 1 (A1) in ethyl acetate (solid content: 50.0% by weight)], 3.31 g of aliphatic isocyanate compound 1 (B1 ), 1.76g of aliphatic isocyanate compound 2 (B2), 0.47g of polyisoprene polyol 1 (C1) and 0.94g of 3-glycidyloxypropyltriethoxysilane (D1) were mixed and then added Ethyl acetate solution was used so that the solid content was 35%, to prepare the adhesive for laminating sheets of Example 1.

Embodiment 2-9 and comparative example 1-5

[0175] In the same manner as in Example 1, according to the formulations shown in Table 2-Table 4, components (A) to (D) were mixed to prepare the laminated sheets of Examples 2-9 and Comparative Examples 1-5. Adhesives for wood.

[0176] [Table 2]

[0177]

[0178] [table 3]

[0179]

[0180] [Table 4]

[0181]

[0182]

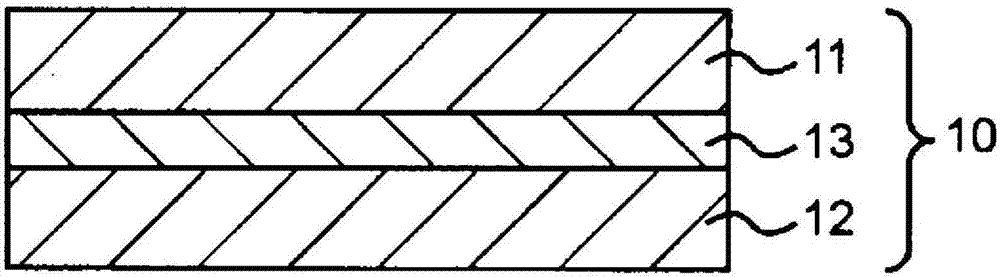

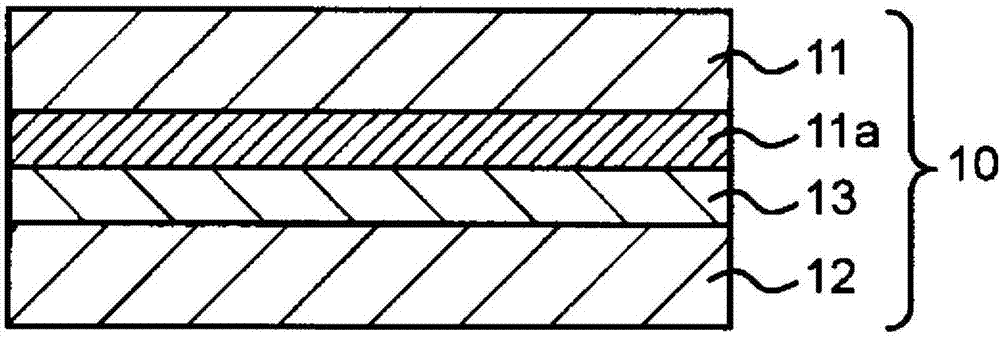

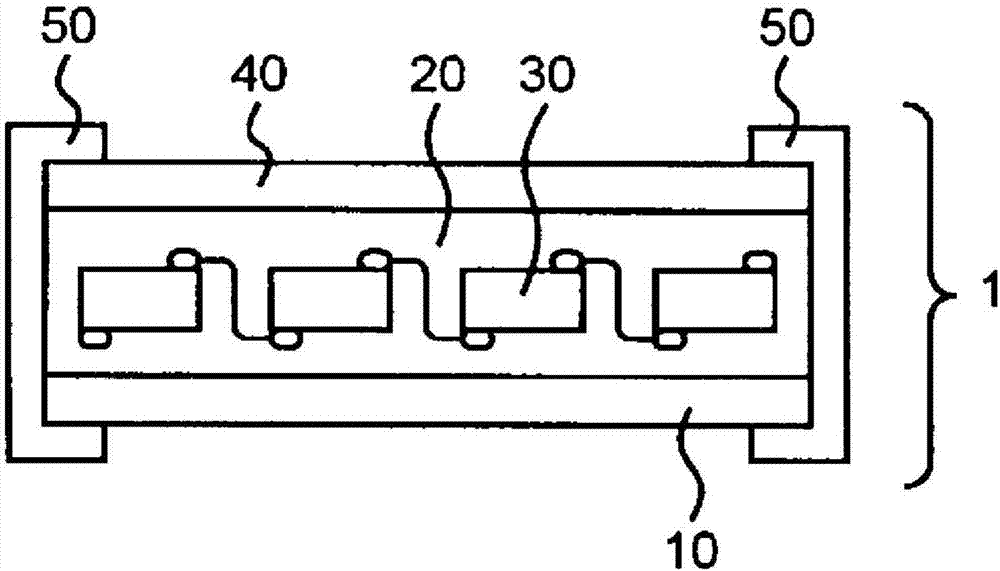

[0183] The adhesive for laminating sheets of Example 1 was applied to a transparent polyethylene terephthalate (PET) sheet (polyester film: OE300EW36 (trade name) manufactured by Mitsubishi Chemical Corporation), so that the weight of the solid component is 10g / m 2 , and then dried at 80°C for 5 minutes.

[0184] A surface-treated PET film (SHINEBEAM Q3215 (trade name) manufactured by TOYOBO CO.LTD) was spread on the PET sheet so that the adhesive-coated surface of the PET sheet was covered with the surface-treated surface of the PET film. s surface. Using a hot roll press, the PET sheet and film were pressed at a speed of 5 m / min under a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com