Laminated film

A laminated film and laminated technology, applied in the direction of layered products, synthetic resin layered products, polarizing elements, etc., can solve the problems of polarizing plates that cannot be used in liquid crystal displays, product yield reduction, and insufficient suppression. Achieve good appearance, less color unevenness, and suppress UV deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

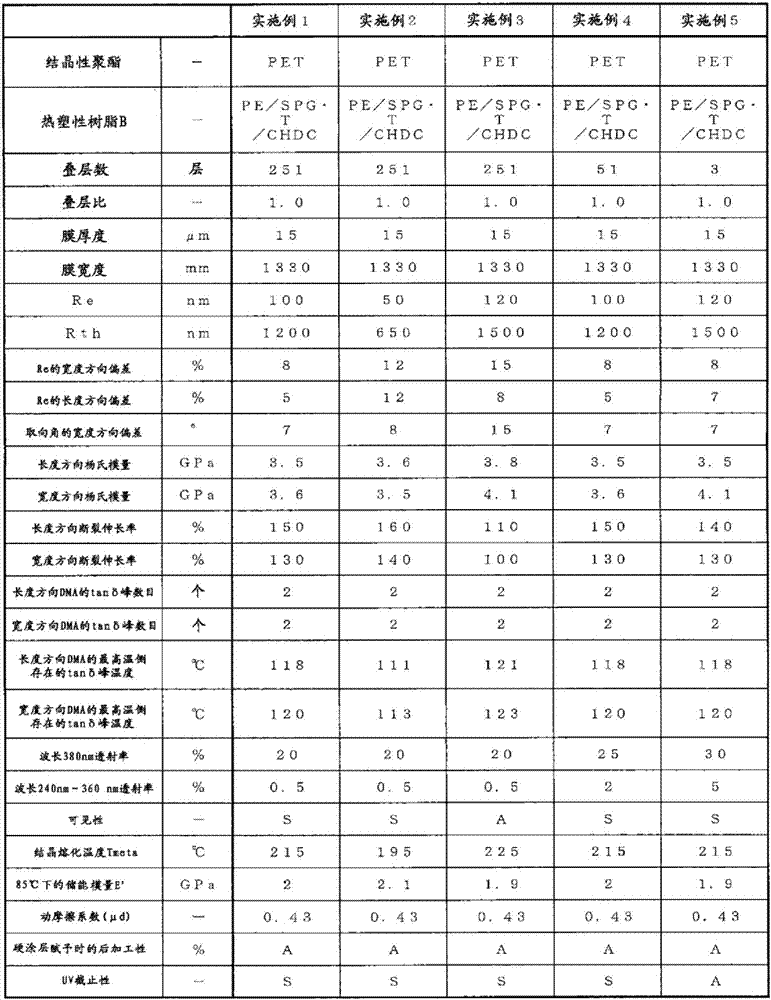

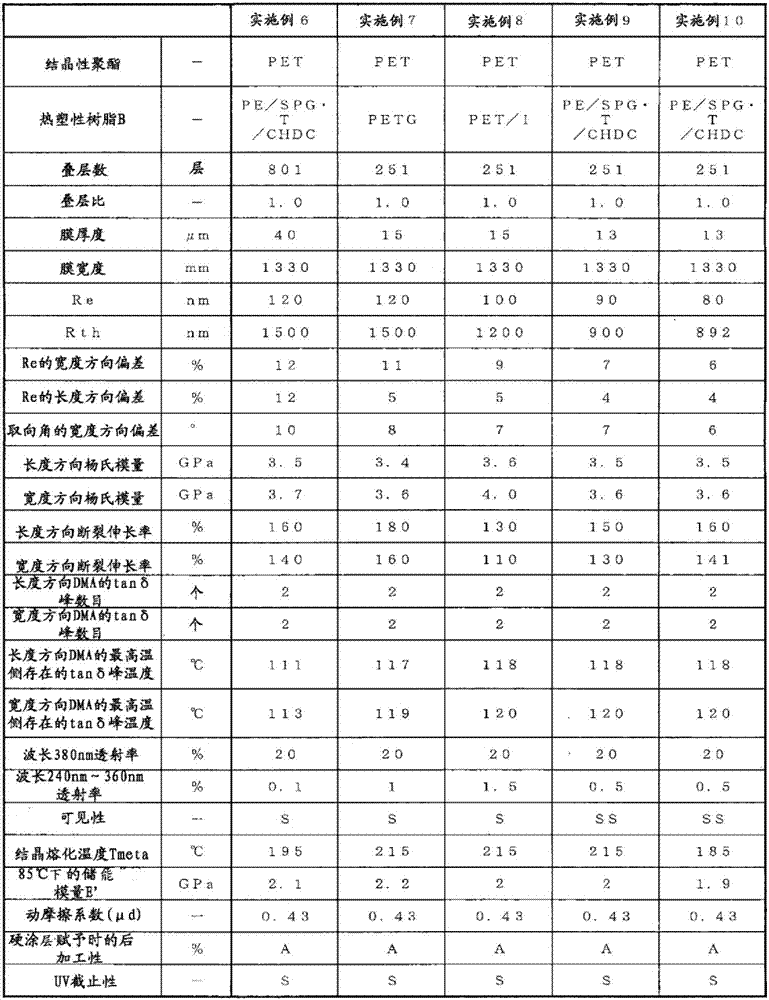

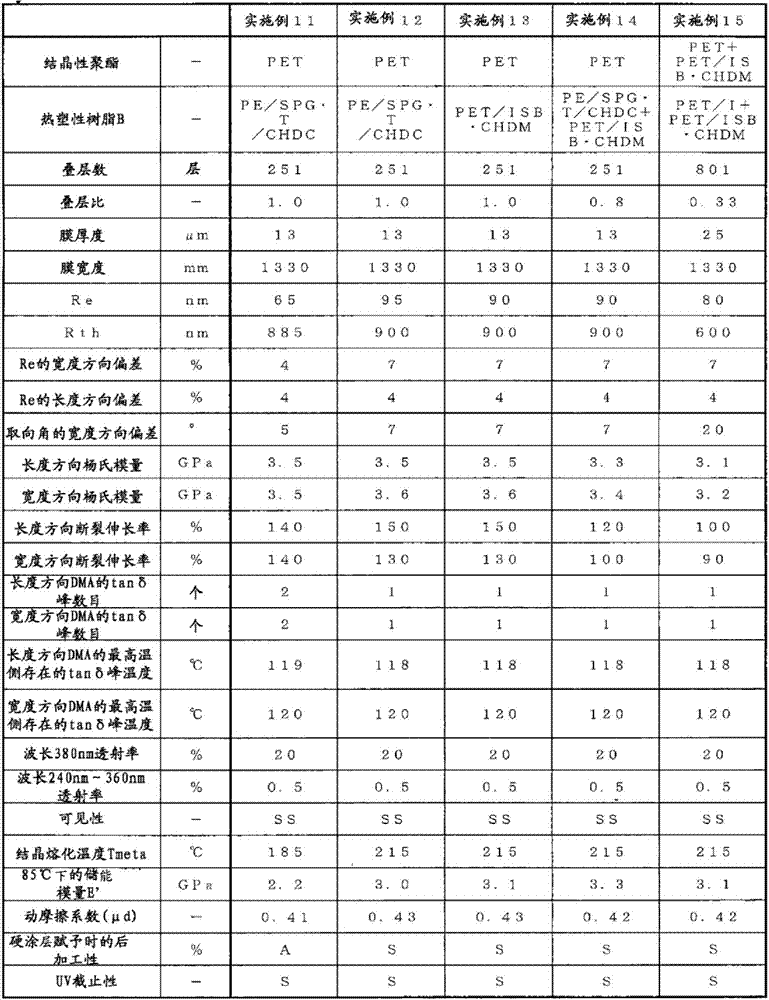

Embodiment 1

[0118] As the crystalline polyester, polyethylene terephthalate (PET) having a melting point of 258° C. was used. As the thermoplastic resin B, ethylene terephthalate (PE / SPG T / CHDC) copolymerized with 15 mol% of spirodiol and 25 mol% of cyclohexanedicarboxylic acid as an amorphous resin having no melting point was used. ). The above-mentioned PE / SPG·T / CHDC 98% by mass, 2,4,6-tris(2-hydroxy-4-hexyloxy-3-methylphenyl)-1,3,5-triazine as UVA 2 mass %The raw materials are supplied from the metering hopper to the twin-screw extruder by mixing at this ratio, melted and kneaded at 280°C, discharged from the die in strips, cooled and solidified by a water tank at 25°C, cut into granules, and obtained thermoplasticity. Resin composition (B-1).

[0119] The prepared PET and the thermoplastic resin composition (B-1) were fully dried under vacuum and high temperature so as not to contain moisture, respectively, and then put into two single-screw extruders, and melt-kneaded at 280°C. Ne...

Embodiment 2

[0123] In Example 1, a laminated film was obtained in the same manner as in Example 1, except that the draw ratio during stretching in the film width direction was 3.6 times and the heat treatment temperature was 200°C. Table 1 shows the evaluation results of the obtained laminated film.

Embodiment 3

[0125] In Example 2, a laminated film was obtained in the same manner as in Example 1 except that the heat treatment temperature was set at 235°C. Table 1 shows the evaluation results of the obtained laminated film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com