Moulded circuit module, and production method therefor

A circuit module and molding technology, which is applied in the direction of circuits, printed circuits, circuit devices, etc., can solve problems such as inability to function and reduce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

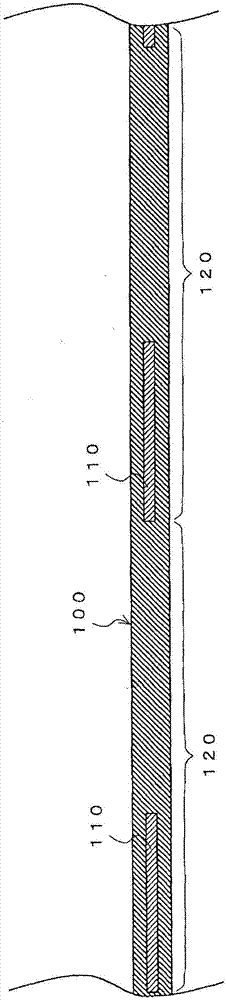

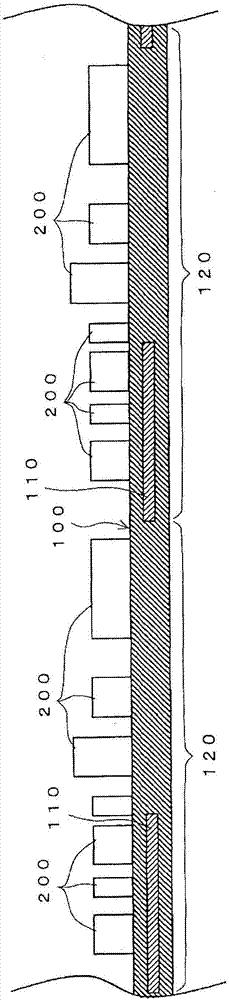

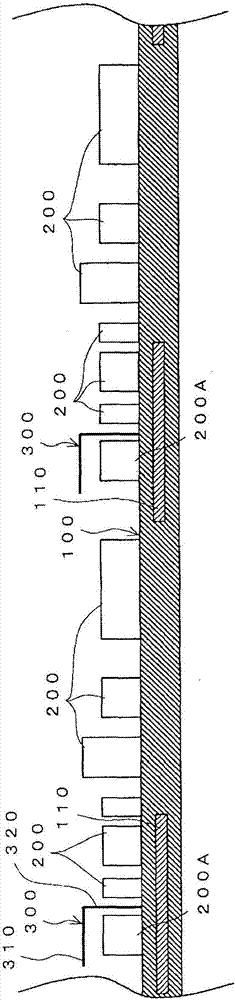

[0092] Hereinafter, a preferred embodiment of the method for manufacturing a molded circuit module according to the present invention will be described with reference to the drawings.

[0093] In this embodiment, a molded circuit module is manufactured using the substrate 100 shown in FIG. 1( a ).

[0094] The substrate 100 may be a very general substrate, and the substrate 100 of this embodiment is also a very general substrate. The substrate 100 includes wiring (not shown). The wiring is a wiring that conducts to an electronic component described later and supplies power to the electronic component, and is a well-known or well-known wiring. Wiring is designed to enable the above functions. The wiring may be provided on the substrate 100 by any method, and may be provided anywhere on the substrate 100 . For example, wiring may be provided on the surface of the substrate 100 by printing. The substrate 100 in this case is generally called a printed wiring board. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com