Cleaning method for ultrafiltration membrane used in seawater desalination

An ultrafiltration membrane and water washing technology, applied in chemical instruments and methods, ultrafiltration, seawater treatment, etc., can solve the problems of long time, the influence of total water production, and the influence of cleaning time on the ultrafiltration process section, so as to save cleaning chemicals. , the effect of shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

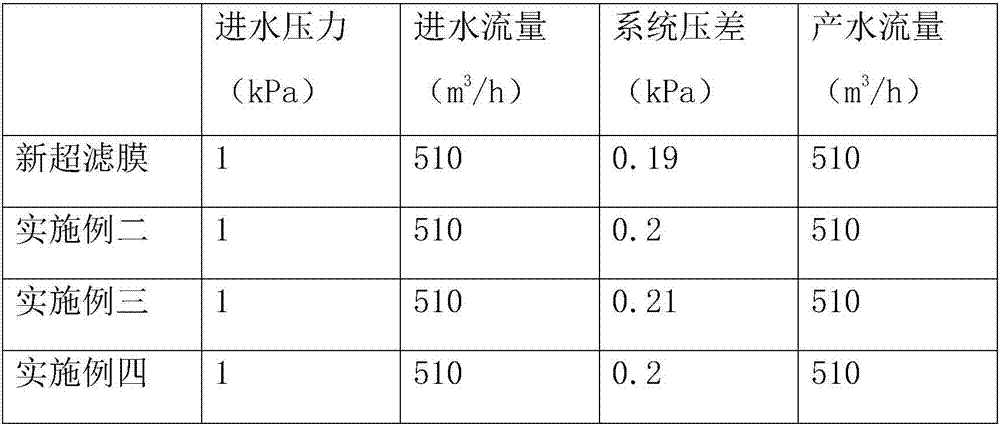

Examples

Embodiment 1

[0019] A method for cleaning an ultrafiltration membrane in seawater desalination applications, comprising the following steps:

[0020] (1) Water flushing or chemically enhanced backwashing;

[0021] (2) Pickling: The pickling solution uses citric acid solution with a mass fraction of 1% or an oxalic acid solution with a mass fraction of 2-10%; the water temperature is 30-35°C; the pickling flow rate is 150-200m 3 / h, the pickling cycle time is 1-2h, ph=2; the pickling solution also contains EDTA;

[0022] (3) Soaking: after the cycle ends, the soaking time is 1-2h, and the soaking solution is a pickling solution;

[0023] (4) Water backwash or chemically enhanced backwash, the chemically enhanced backwash flux is 250lmh.

[0024] The specific steps of pickling are: configure a pickling solution with a pH of 2, and perform variable flow circulation on the ultrafiltration membrane group, with a circulation flow of 150m 3 / h cycle for 15 minutes, the flow rate rises to 175m ...

Embodiment 2

[0028] A cleaning method for ultrafiltration membranes in seawater desalination applications, comprising the following steps:

[0029] (1) Water flushing, flow rate 175m 3 / h is, the time is 15 to 30 minutes;

[0030] (2) pickling: the pickling solution adopts a citric acid solution with a mass fraction of 1%, and the water temperature is 30°C; the pickling cycle time is 1h, and ph=2;

[0031] (3) Soaking: after the cycle ends, the soaking time is 1h, and the soaking solution is the pickling solution;

[0032] (4) Chemically enhanced backwashing, the chemically enhanced backwashing flux is 250LMH (liter / square meter / hour).

[0033] The specific steps of pickling are: configure a pickling solution with a pH of 2, and perform variable flow circulation on the ultrafiltration membrane group, with a circulation flow of 150m 3 / h cycle for 15 minutes, the flow rate rises to 175m within 15 seconds 3 / h cycle for 15 minutes, and the flow will rise to 200m within 15 seconds 3 / h c...

Embodiment 3

[0035] A cleaning method for ultrafiltration membranes in seawater desalination applications, comprising the following steps:

[0036] (1) Chemically enhanced backwash with a flux of 250LMH;

[0037] (2) pickling: the pickling solution adopts oxalic acid solution with a mass fraction of 2%, and simultaneously adds 100 ppm of EDTA; the water temperature is 35° C.; the pickling cycle time is 2 hours, and ph=2;

[0038] (3) Soaking: after the cycle ends, the soaking time is 2h, and the soaking solution is the pickling solution;

[0039] (4) Water backwashing, the flux is 250LMH, and the time is 2 minutes.

[0040] The specific steps of pickling are: configure a pickling solution with a pH of 2, and perform variable flow circulation on the ultrafiltration membrane group, with a circulation flow of 150m 3 / h cycle for 15 minutes, the flow rate rises to 175m within 15 seconds 3 / h cycle for 15 minutes, and the flow will rise to 200m within 15 seconds 3 / h cycle for 15 minutes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com