Dangerous waste cyclic treatment system

A technology for cyclic treatment and hazardous waste, which is used in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc. It can solve the problems of incomplete treatment, backwardness, and insufficient utilization of waste gas and waste heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

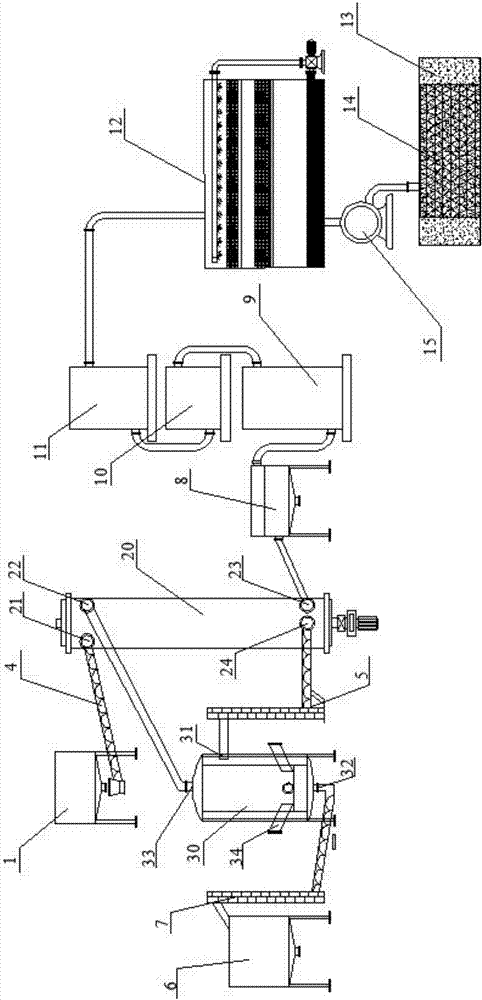

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] figure 1 It is a structural schematic diagram of the hazardous waste recycling treatment system of the present invention. see figure 1 , the embodiment of the present invention provides a hazardous waste recycling treatment system, including: a hazardous waste bin 1, a drying device 20 and a plasma melting furnace 30, the top of the drying device 20 is provided with a first feeding port 21 and The first air inlet 22, the bottom of the drying device 20 is provided with a first discharge port 24 and a first exhaust port 23, and the hazardous waste bin 1 is connected to the first inlet through the first conveying device 4. The feed port 21 is connected, the top of the plasma melting furnace 30 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap