Thiourea modified cardanol aldehydeamine epoxy curing agent and preparation method thereof

A technology of phenalkamine epoxy and curing agent, applied in the field of curing agent, thiourea modified cardanol phenol amine epoxy curing agent and preparation, can solve the problems of inconvenient construction, high viscosity, etc. Excellent effect of toxicity, low temperature curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

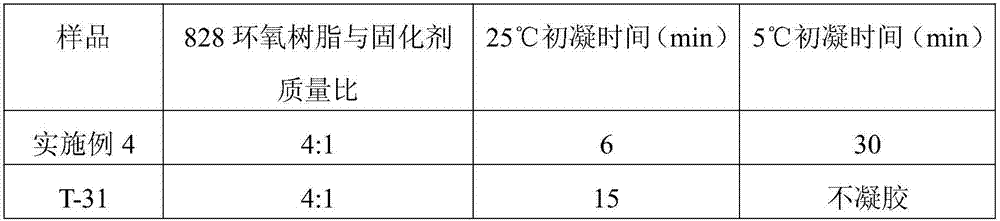

Examples

Embodiment 1

[0022] 1. A thiourea modified cardanol phenalkamine epoxy curing agent, which comprises the following raw materials: thiourea 76g, diethylenetriamine 103g, cardanol 304g, 37% formaldehyde solution 81g.

[0023] 2, the preparation method of thiourea modified cashew nut phenalkamine epoxy curing agent, it may further comprise the steps:

[0024] (1) Add 103g of diethylenetriamine and 76g of thiourea into the reaction flask, under the protection of nitrogen, mix, heat and stir; heat to 50±5°C, and raise the temperature to 130°C after the thiourea is completely melted ±5°C; reflux reaction for 3 hours, and naturally cooled to room temperature to obtain a low-viscosity, dark yellow thiourea-modified amine;

[0025] (2) Then add cardanol 304g in the reaction flask, mix, heat and stir; then heat up to 50°C, start to add 81g of 37% formaldehyde solution dropwise, control the drop rate of formaldehyde so that the temperature does not exceed 100°C; then heat up to 100°C Continue to kee...

Embodiment 2

[0028] 1, a kind of thiourea modified cardanol phenalkamine epoxy curing agent, it comprises following raw material: thiourea 76g, triethylenetetramine 146g, cardanol 304g, 37% formaldehyde solution 81g.

[0029] 2, the preparation method of thiourea modified cashew nut phenalkamine epoxy curing agent, it may further comprise the steps:

[0030] (1) Add 146g of diethylenetriamine and 76g of thiourea into the reaction flask, mix, heat and stir under the protection of nitrogen; heat to 50±5°C, and raise the temperature to 130±5°C after the thiourea is completely melted, Reflux reaction for 3 hours, and naturally cool to room temperature to obtain a low-viscosity, dark yellow thiourea-modified amine;

[0031] (2) Then add cardanol 304g in the reaction flask, mix, heat and stir; then heat up to 50°C, start to add 81g of 37% formaldehyde solution dropwise, control the drop rate of formaldehyde so that the temperature does not exceed 100°C; then heat up to 100°C Continue to keep wa...

Embodiment 3

[0034] 1, a kind of thiourea modified cardanol phenalkamine epoxy curing agent, it comprises following raw material: thiourea 152g, diethylenetriamine 206g, cardanol 304g, 37% formaldehyde solution 162g.

[0035] 2, the preparation method of thiourea modified cashew nut phenalkamine epoxy curing agent, it may further comprise the steps:

[0036] (1) Add 206g of diethylenetriamine and 152g of thiourea into the reaction flask, and mix, heat and stir under the protection of nitrogen; heat to 50°C, and raise the temperature to 135°C after the thiourea is completely melted; reflux reaction for 3h, Cool naturally to room temperature to obtain low viscosity, dark yellow thiourea modified amine;

[0037] (2) Then add cardanol 304g in the reaction flask, mix, heat and stir; then heat up to 50°C, start to add 162g of 37% formaldehyde solution dropwise, control the drop rate of formaldehyde so that the temperature does not exceed 100°C; then heat up to 105°C Continue to keep warm for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com