Multi-material automatic real-time mixed electric spinning direct writing device

An electrospinning direct writing, multi-material technology, applied in textiles and papermaking, filament forming treatment, fiber treatment and other directions, can solve the problems of unstable micro-nano structure performance, difficult to achieve uniformity, non-uniformity, etc., to prevent precipitation Effects of delamination or severe agglomeration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

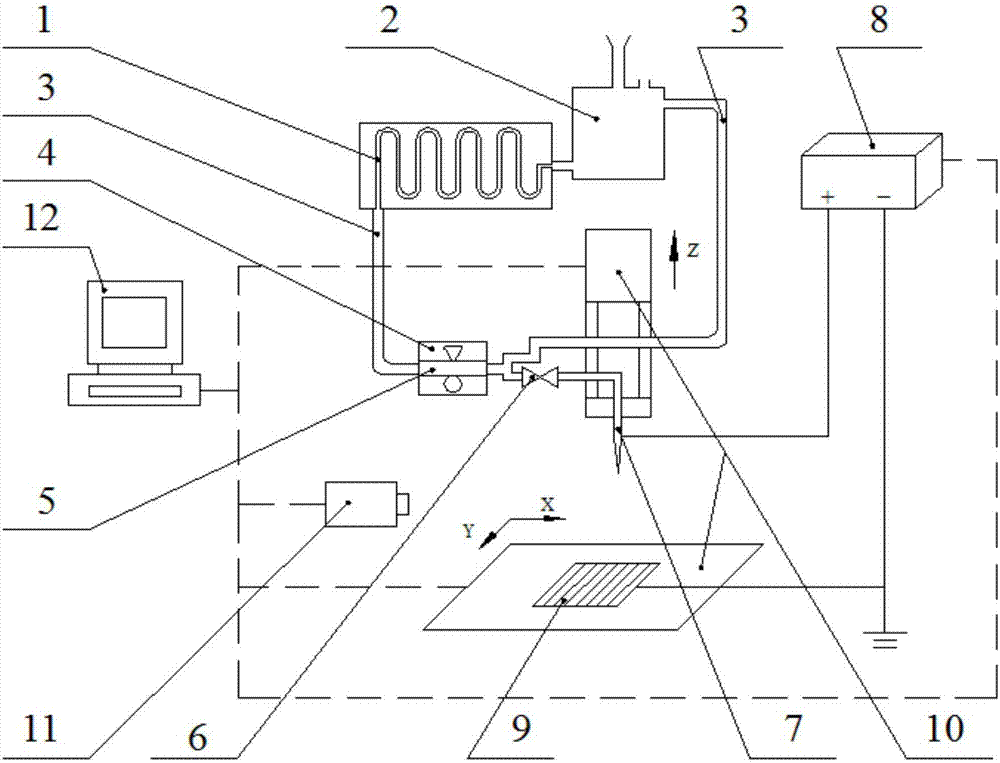

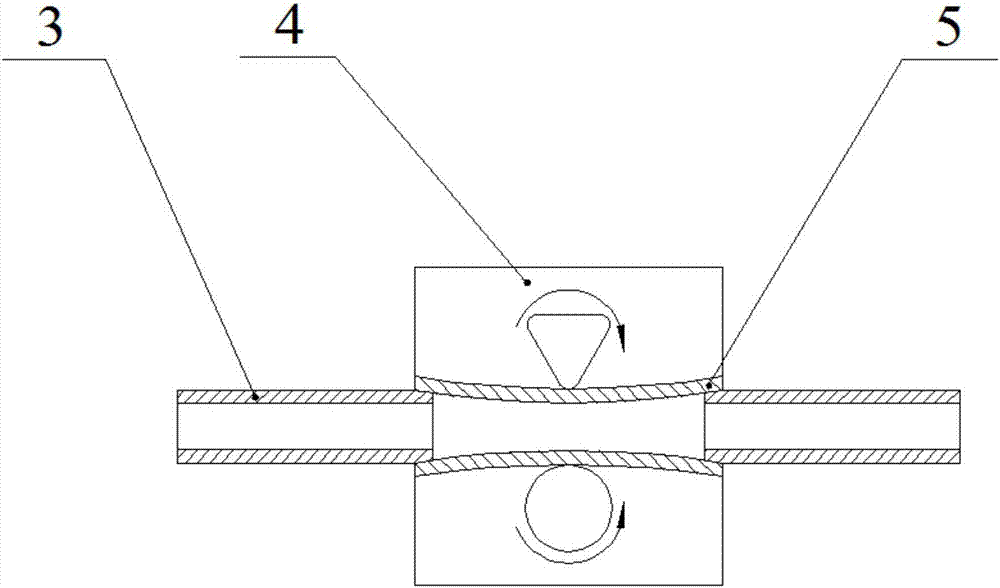

[0019] see figure 1 , the embodiment of the present invention is provided with a mixing microchannel 1, a liquid reservoir 2, an infusion pipeline 3, a driver 4, a liquid supply hose 5, a shut-off valve 6, a nozzle 7, a high-voltage power supply 8, a collecting plate 9, and an XYZ three-dimensional mobile platform 10. CCD microscope 11 and computer 12.

[0020] One end of the mixed microchannel 1 is connected to the liquid reservoir 2, and the other end of the mixed microchannel 1 is connected to the infusion pipeline 3. The upper end of the liquid reservoir 2 has a liquid supply inlet and a port connected to the outside air, and one end of the infusion pipeline 3 A liquid supply hose 5 is connected, and a driver 4 is installed on the liquid supply hose 5. The other end of the liquid supply hose 5 is connected to two infusion pipelines 3, one of whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com