No stretch pressure ironing machine

An ironing machine and pressure technology, applied in ironing machines, washing devices, textiles and papermaking, etc., can solve the problems of easy relative sliding of ironing belts, bending deformation of rollers, and reduction of tension of ironing belts, etc., to achieve ironing The effect of flat and dry effect is good, reducing the requirements of strength and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

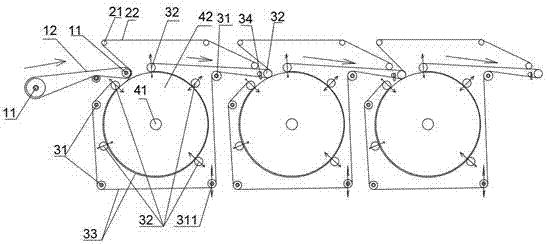

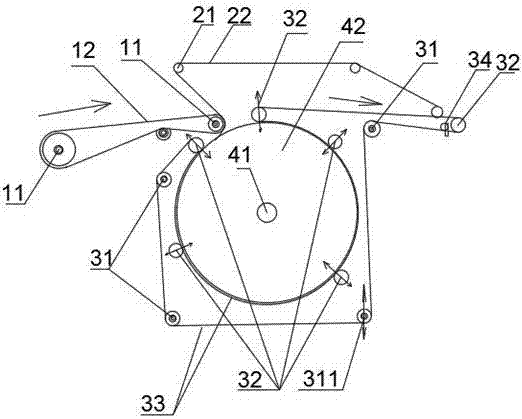

[0029] A non-stretching pressure ironing machine, including a conveying mechanism and an ironing and drying mechanism, the conveying mechanism conveys home textiles and clothes to the ironing and drying mechanism, and the conveying mechanism assists the ironing and drying mechanism to iron the home textiles and clothes Flat drying work, wherein the conveying mechanism includes an external conveying unit, a guide unit and an internal conveying unit, and the ironing and drying mechanism is composed of an ironing and drying unit;

[0030] The external conveying unit includes conveying rollers 11 and conveying belts 12, at least two conveying rollers 11 supply a set of conveying belts 12 for external conveying of home textiles and clothes;

[0031] Described guiding unit comprises guiding belt support roller 21 and guiding belt 22, at least two guiding belt supporting rollers 21 supply a set of guiding belt 22, on the one hand guiding belt 22 obtains the same moving direction as he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com