Method of measuring sound pressure amplitude in liquid through using acoustic suspension liquid drop

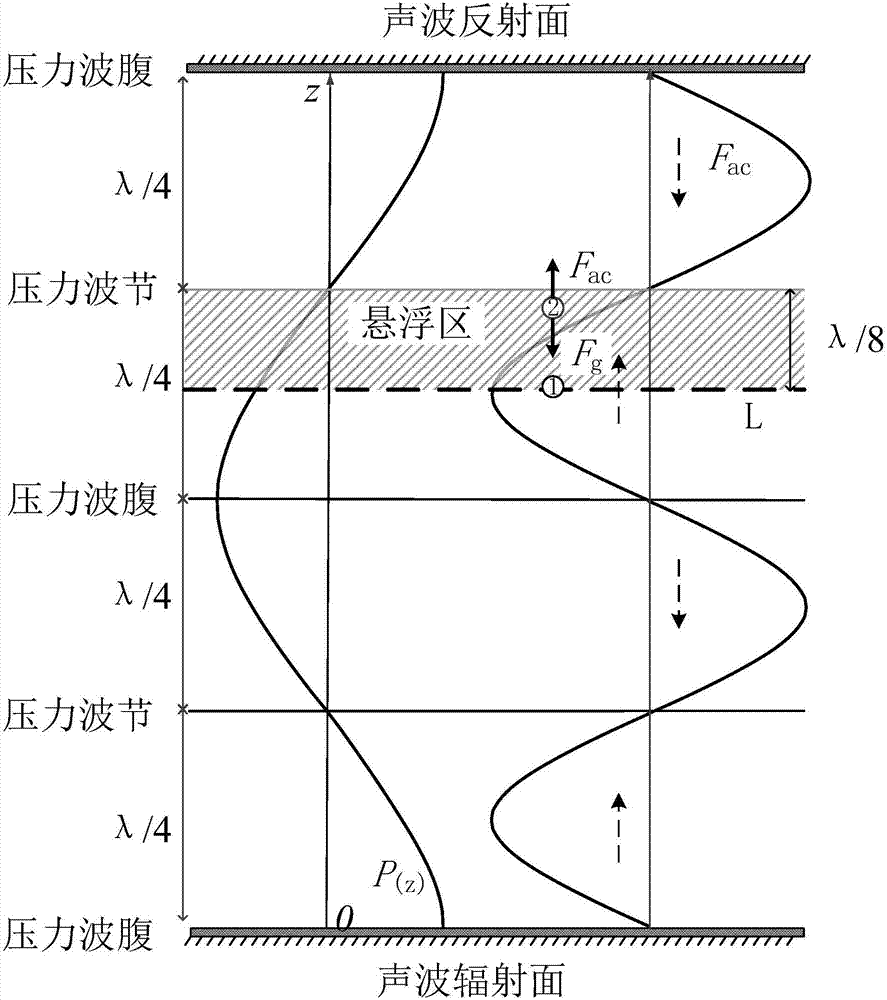

A technology of sound pressure amplitude and sound levitation, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, using wave/particle radiation, etc., can solve the problems of sound field distribution interference, cavitation at the measurement place, damage to hydrophones, etc., to achieve The effect of accurate sound pressure amplitude, accurate measurement results and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

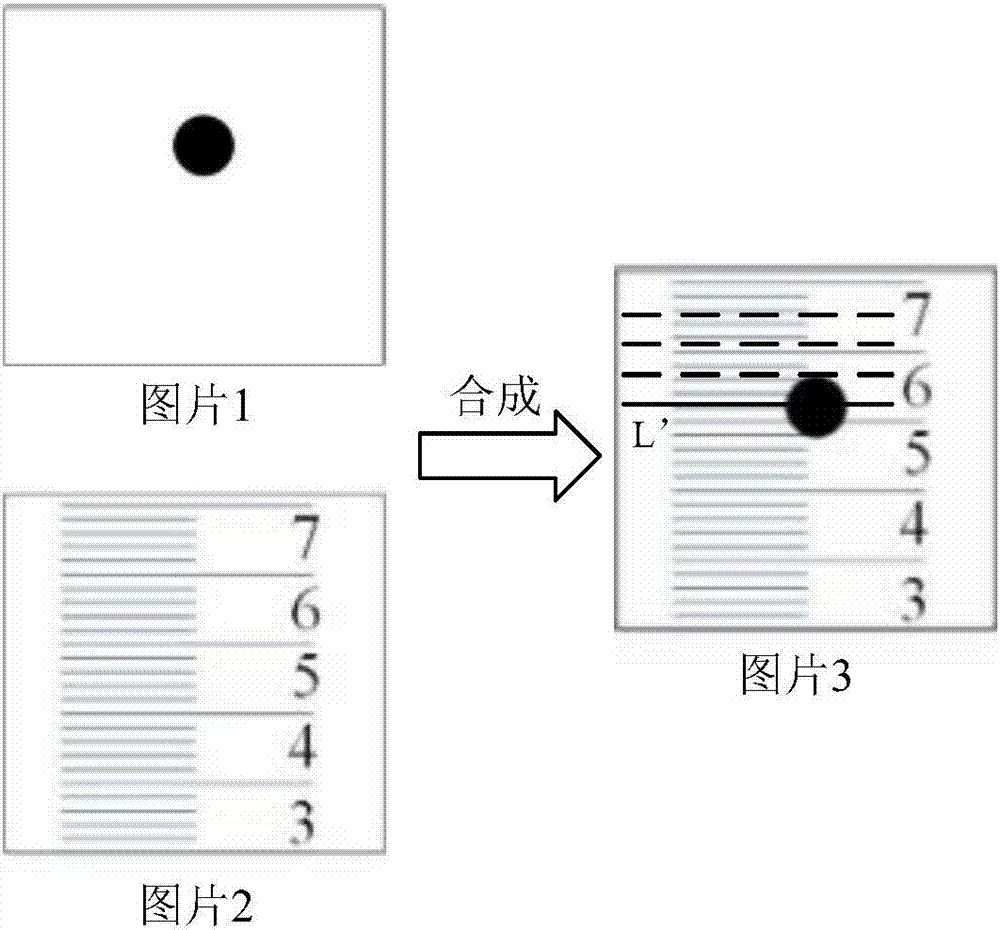

Method used

Image

Examples

Embodiment

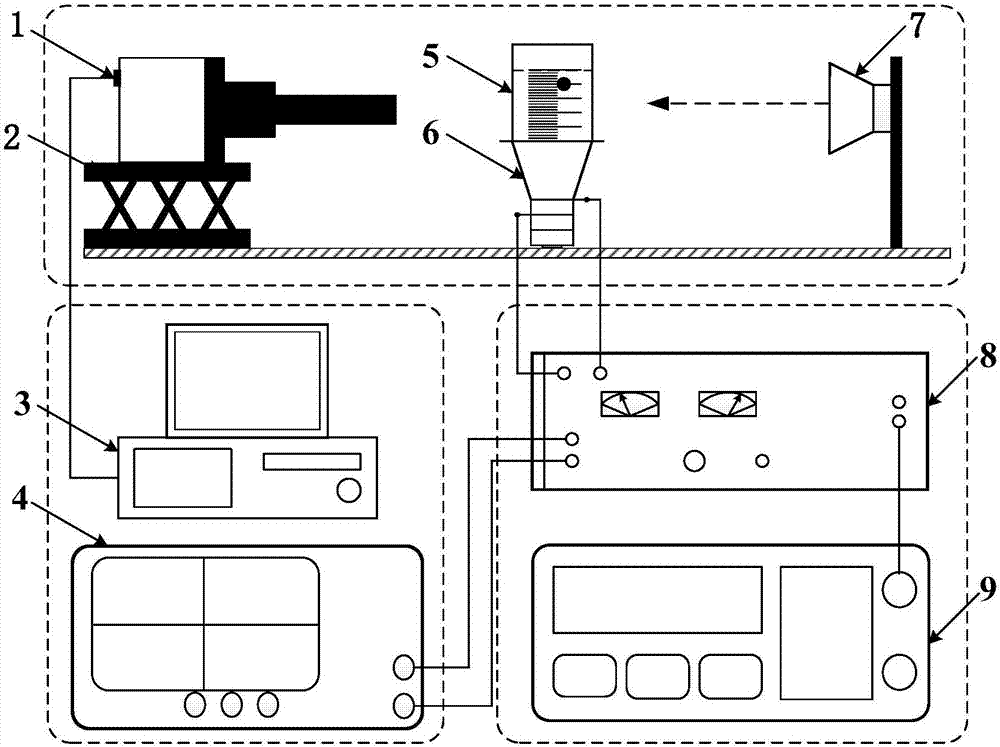

[0040] With simethicone as the continuous liquid phase and water droplets as tiny suspended liquid droplets, the method for measuring the amplitude of sound pressure of the present invention adopts the following measurement steps:

[0041] Step 1, add simethicone to the attached figure 2 In the transparent rectangular tank body 5, the height of the silicone oil liquid surface from the sound radiation surface is a wavelength λ (here, take the wavelength λ of 20kHz ultrasonic waves in dimethyl silicone oil as an example), and let it stand for 10 minutes to make the bubbles in the silicone oil released so as not to affect the experimental results;

[0042] Step 2, using a micropipette with a volume range of 0.1 μL-1 μL to drop tiny water droplets into the silicone oil in the rectangular tank 5;

[0043] Step 3, setting the ultrasonic signal of the signal generator 9 as a 20kHz sinusoidal signal, the high-frequency power amplifier 8 amplifies the small sinusoidal signal generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com