A vehicle inverter

A technology for inverters and vehicles, which is applied to the transformation of structural parts of equipment, conversion of AC power input to DC power output, cooling/ventilation/heating transformation, etc. It can solve the problems of long busbar structure, inverter heat rise, Problems such as poor electromagnetic environment, to achieve the effect of compact structure, high electromagnetic compatibility, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

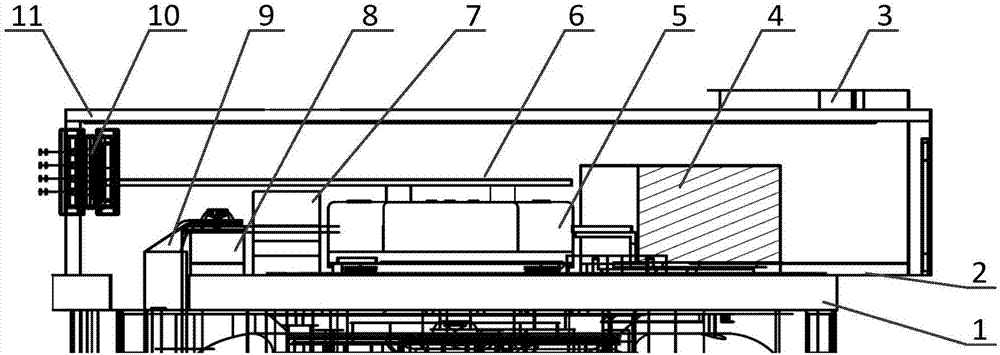

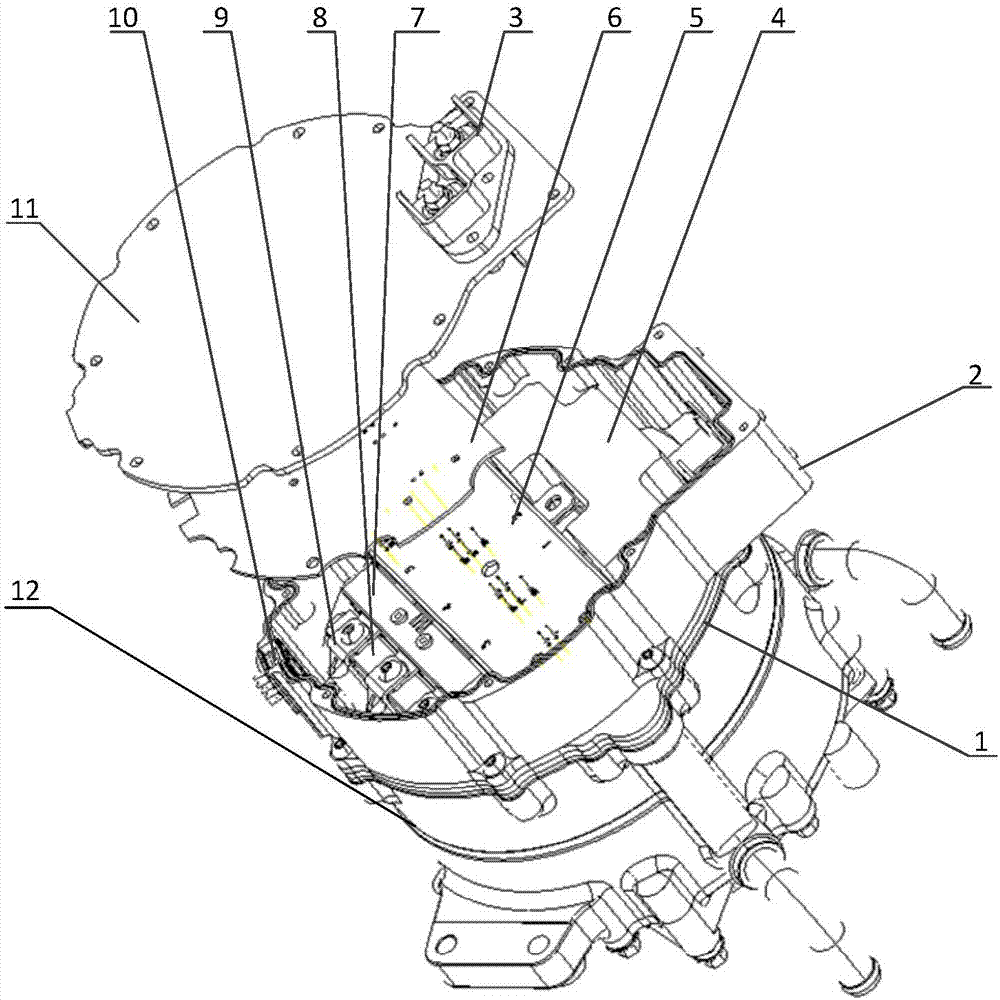

[0024] This embodiment provides a vehicle inverter, which includes a casing, an upper cover and a cooling bottom plate.

[0025] The casing is connected to the motor through bolts, and at the same time, a cooling bottom plate is arranged between the casing and the motor, that is, the cooling bottom plate is also fixed on the rear end cover of the motor, and the bottom of the casing The upper end is fixed with an upper cover, and the upper cover seals the opening of the upper end of the housing.

[0026] The functional components of the vehicle inverter are respectively connected to the cooling bottom plate and the upper cover of the housing in a specific positional relationship, and further realized. Through the compact integration of the various functional components, further realization of The electrical connection of each functional component is simpler and more efficient, and the reliability and power density of the motor inverter are improved.

[0027] Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com