A system and method for automated high-density cultivation of rotifers

A high-density, rotifer technology, applied in animal husbandry and other directions, can solve the problems of seldom popularized and applied, low degree of automation, high operating cost, and achieve the effect of reducing pollutant content, maintaining water quality, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

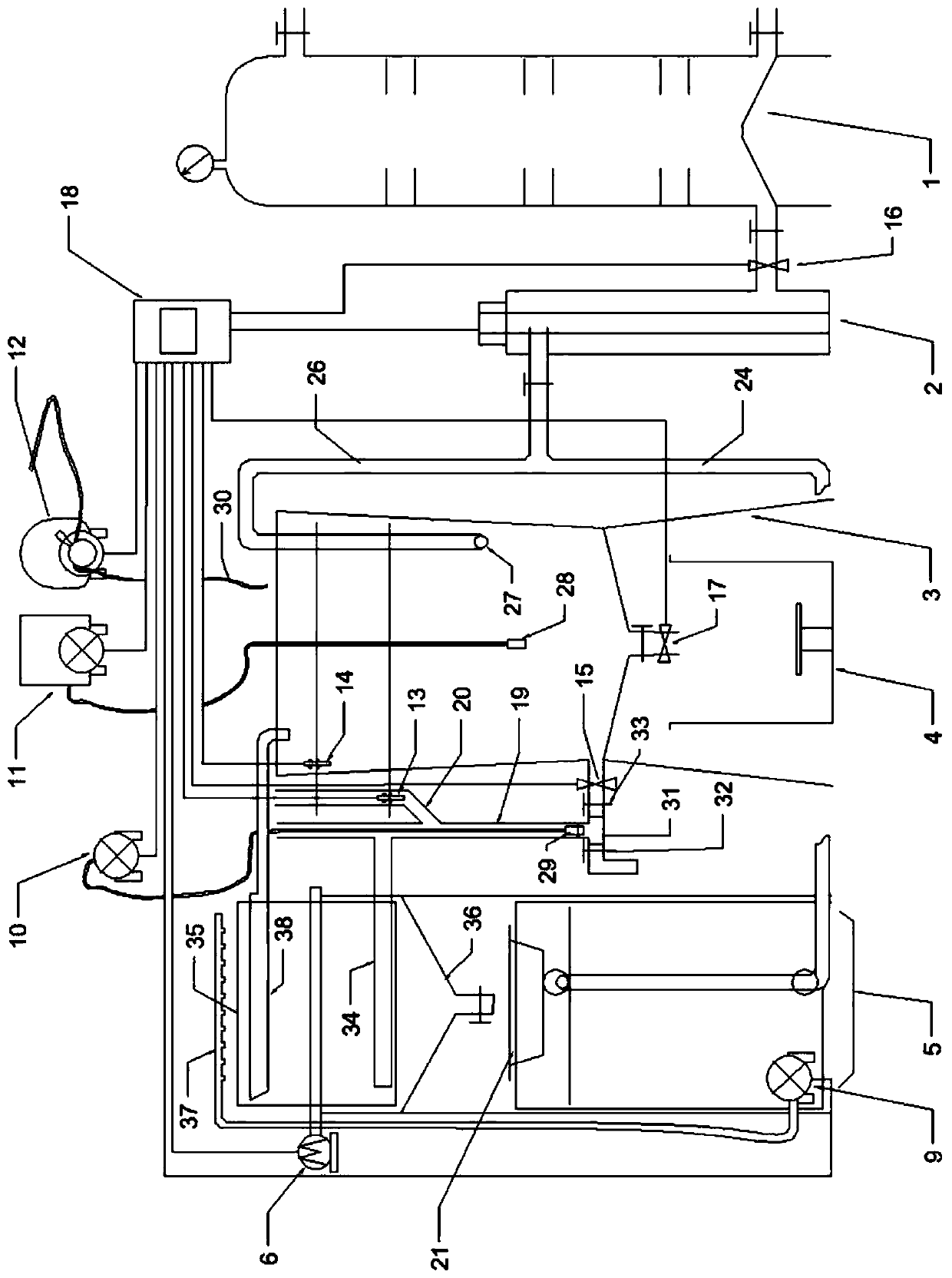

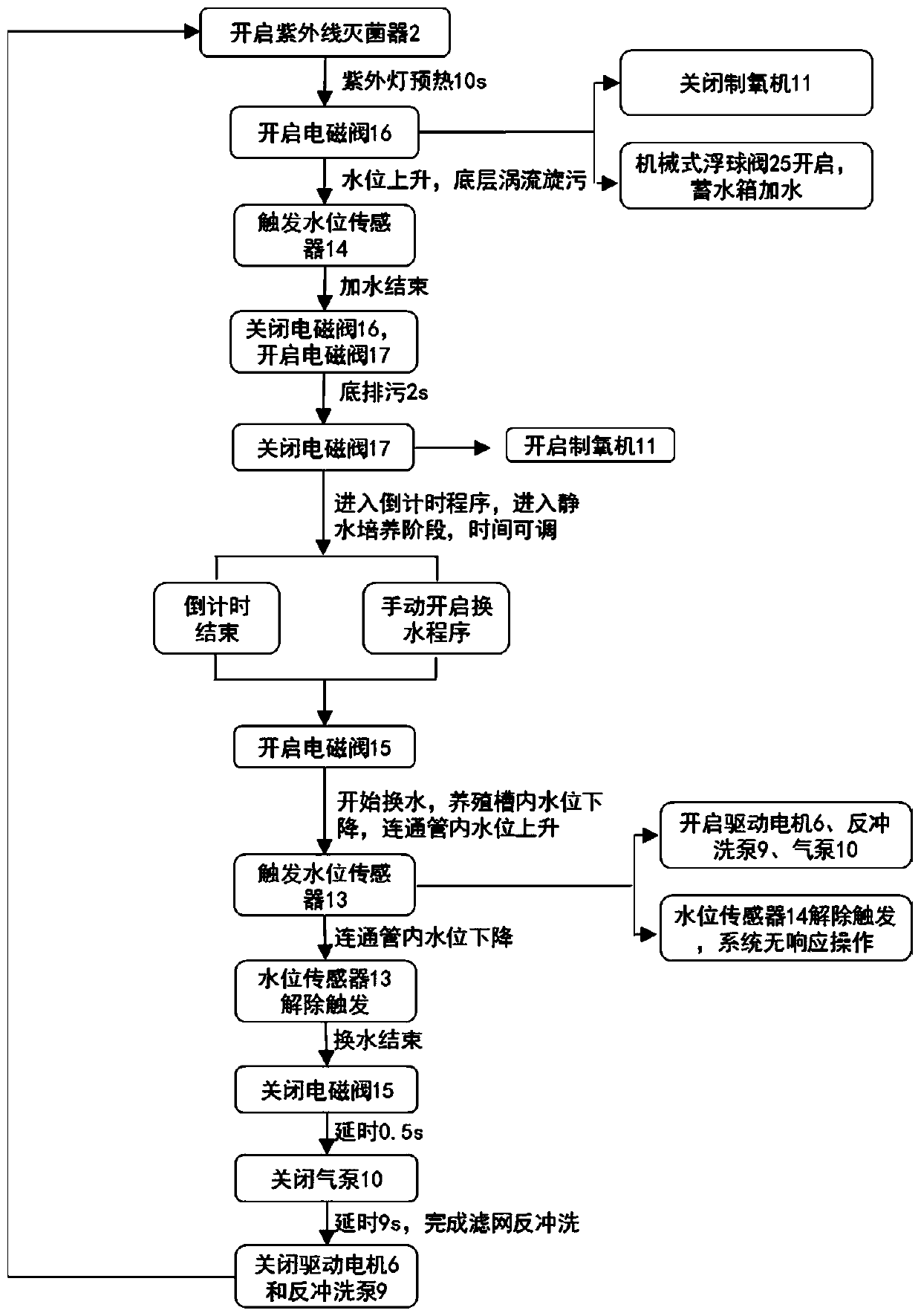

[0043] as attached figure 1 As shown, the device set by the present invention is used to cultivate rotifers, and the parameters of each part are set to be that the source water processor 1 is equipped with an adjustable flow limiting valve, and the limiting flow rate Q is 1.2m 3 / h, the power of the ultraviolet sterilizer 2 is 40W, a single breeding tank is used, the effective volume is 400L, the power of the oxygen generator is adjustable from 0-10L / min, and the maximum power consumption is 550W.

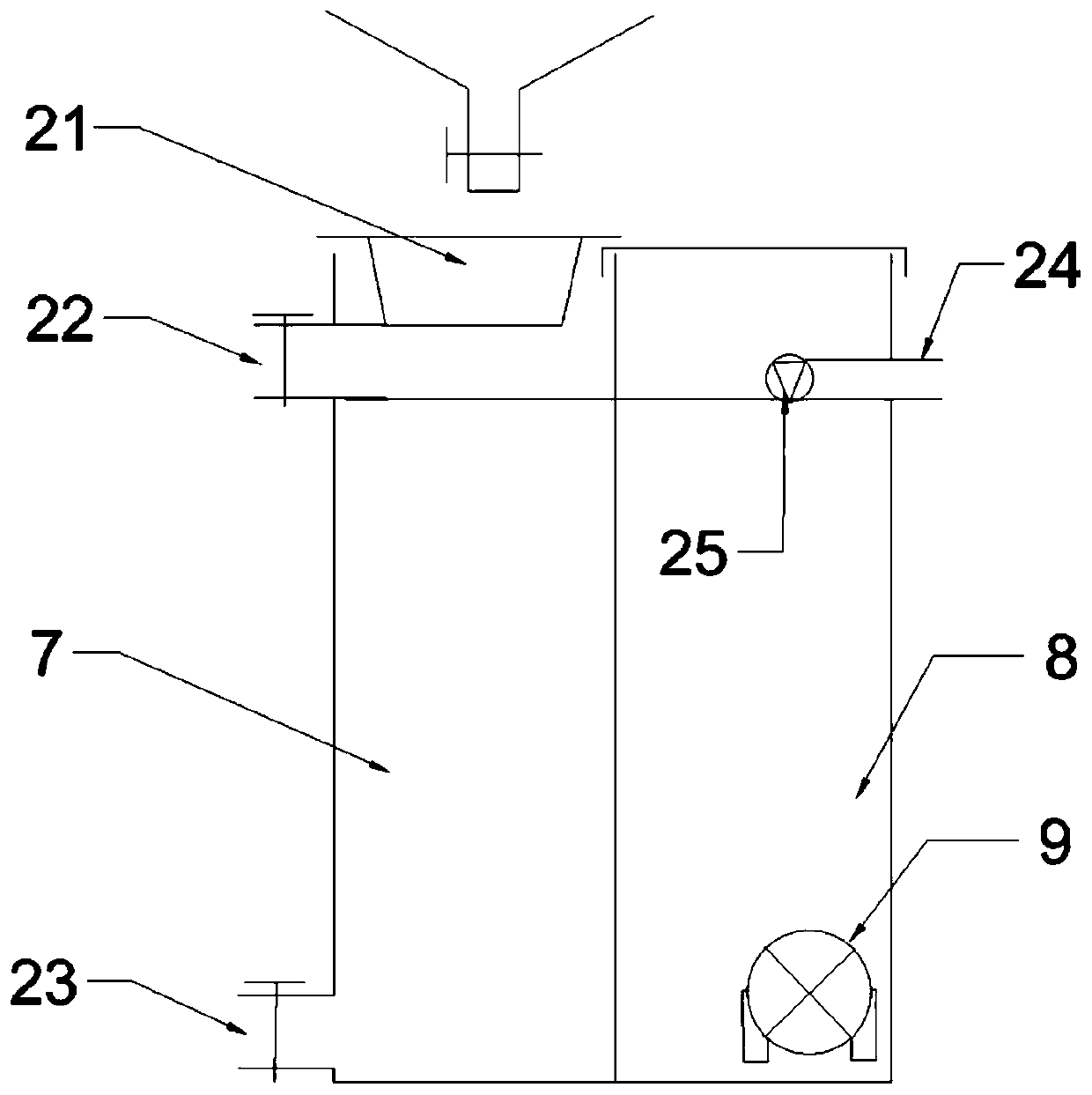

[0044] A feasible connection method of each part is as follows: the water outlet of the source water processor 1 is connected to the solenoid valve 16, and then connected to the water inlet of the ultraviolet sterilizer 2, and the water outlet of the ultraviolet sterilizer is connected to the water inlet pipe 24 and the water inlet pipe 26 , wherein the water inlet pipe 24 is connected to the mechanical float valve 25 to enter the water storage tank 8, the water inlet pipe 26 enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com