Dedicated decrustation device for peanuts

A peeling device and peanut technology, which is applied in the field of grain processing machinery, can solve the problems of poor environment, high damage rate, and low peeling rate, and achieve the effects of reducing costs, ensuring integrity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

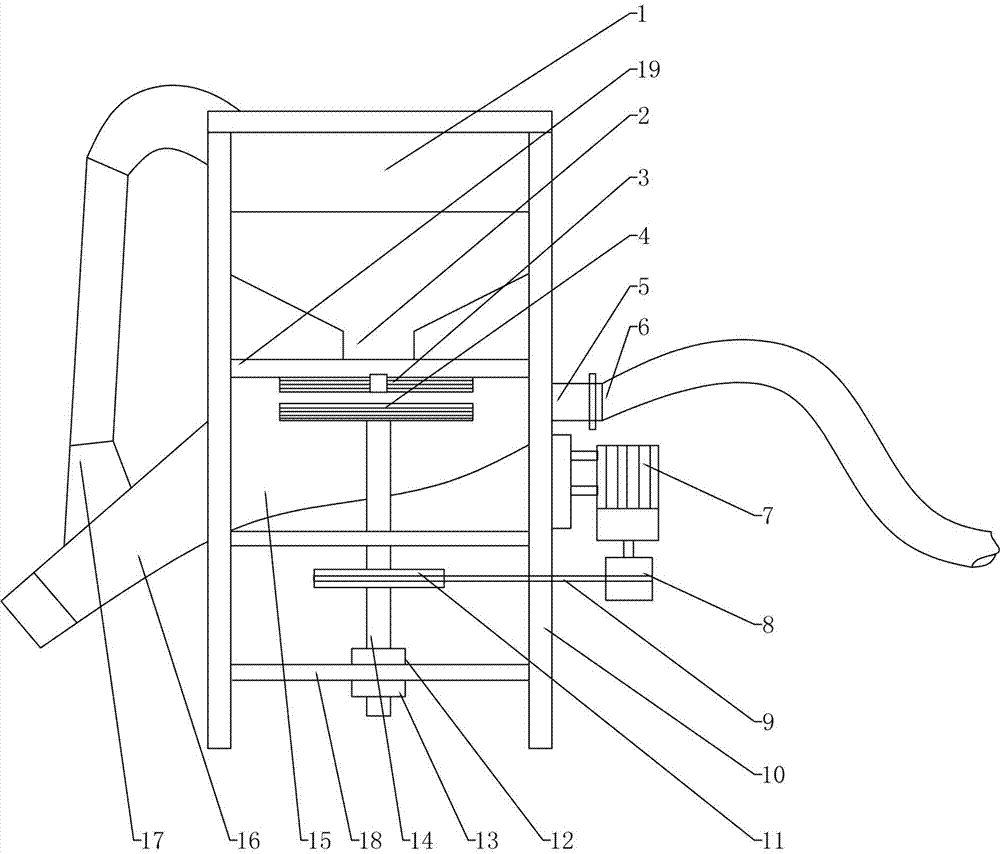

[0013] Such as figure 1 As shown, a special peeling device for peanuts comprises a support 10, the upper end of the support 10 is provided with a hopper 1, the hopper 1 communicates with the silo 15 through the hopper mouth 2, and the silo 15 is provided with a peeling mechanism, which mainly consists of a fixed Grinding disc 3 and rotating grinding disc 4 are made up of, and fixed grinding disc 3 is installed on the base 19 of material bin 15, is opposite to rotating grinding disc 4 and keeps interval, and rotating grinding disc 4 is installed on the rotating shaft 14, and is driven by driving device, and described material There is a discharge port 16 outside the warehouse 15, and a material separation mechanism is installed at the discharge port 16. The material separation mechanism includes an exhaust pipe 17, and an exhaust fan 5 is installed at the rear end of the exhaust pipe 17. The exhaust fan 5 and the filter bag 6 connected.

[0014] Described driving device compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com