Modern intelligent pumping unit

A kind of pumping unit, intelligent technology, applied in the field of modern intelligent pumping unit, can solve the problems of increasing wearing parts, complicated process, unusable transmission structure, etc., to achieve the effect of reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

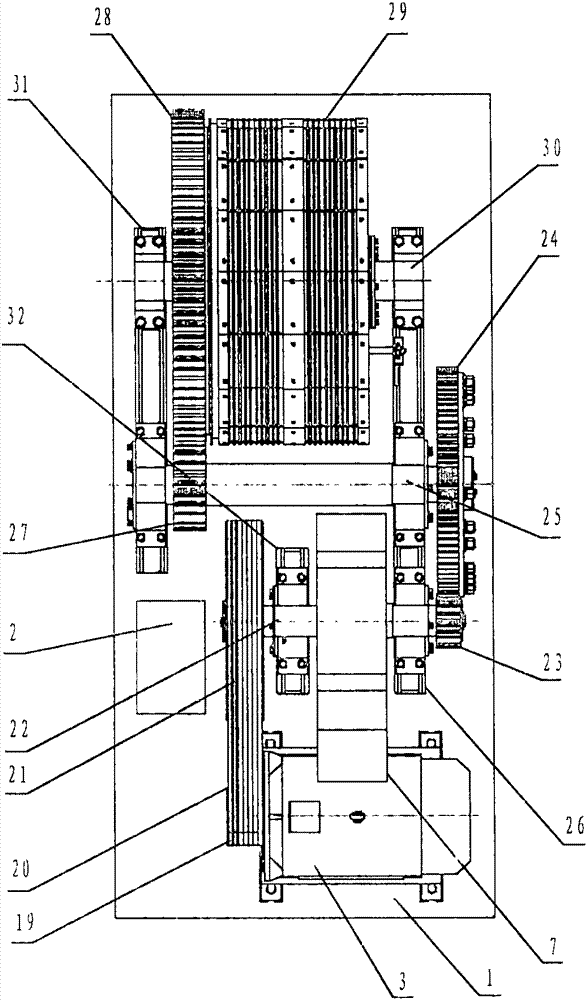

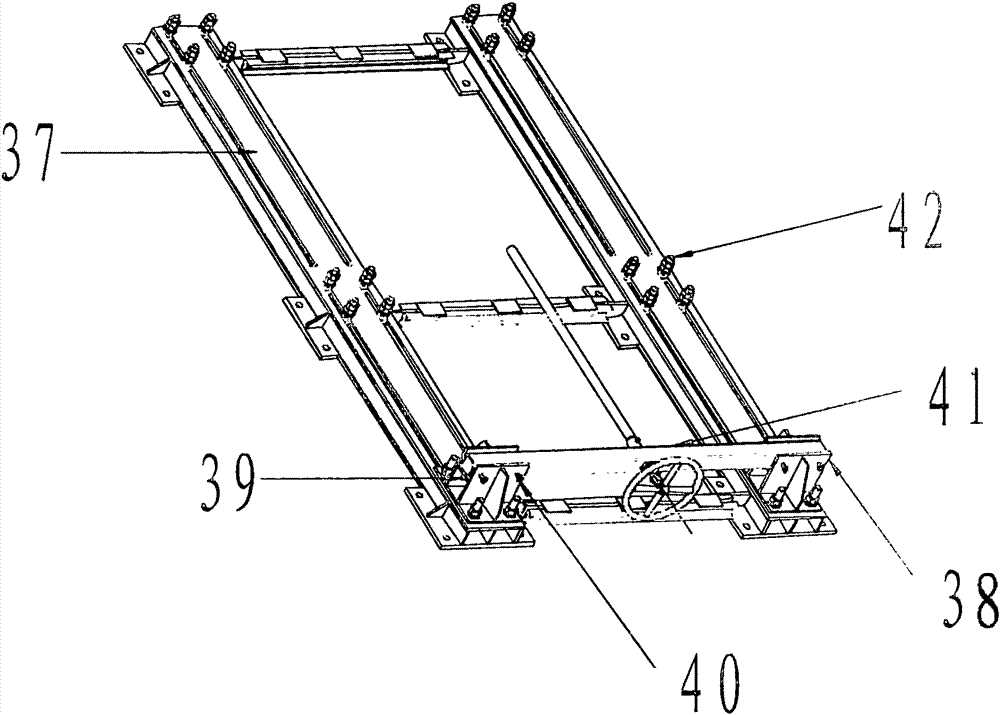

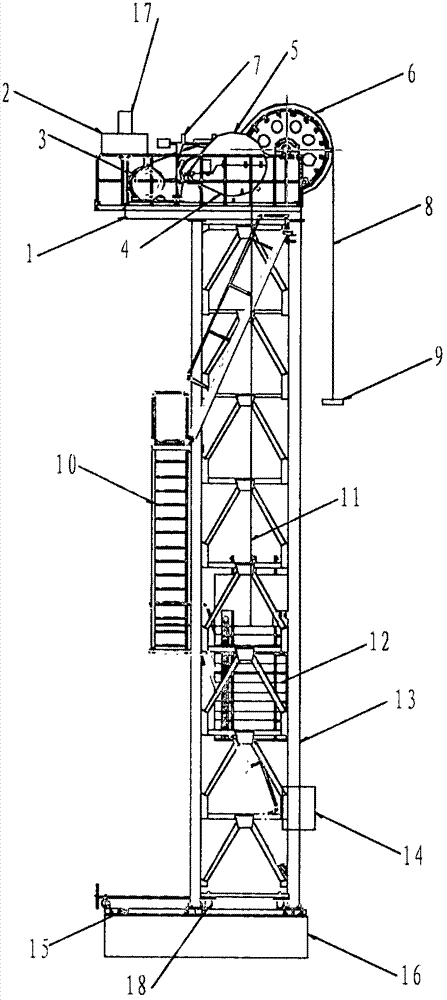

[0020] Such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, the first embodiment of the modern intelligent pumping unit of the present invention includes that it is installed on the operating platform 1 at the top of the tower 13: a control system 2, a reminder light 17, a power system 3, a drum type electromagnetic power-off brake 7, First-level belt transmission 4, second-level gear transmission 5, third-level gear transmission 6, touch screen 14, balance counterweight system 12, drive rope 8, rope hanger 9, counterweight traction rope 11, workover mechanism 18, mobile The mechanism base 15, the control system 2 is a servo control system including an intelligent module and a touch screen, the control system 2 controls the reversing position and speed of the power system 3, and the primary small pulley 19 at the output end of the power system 3 is installed on the first transmission shaft 22 A belt 20 is set on the first-stage large pulley 21 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com