Turbo-charged valve controller

A valve controller, worm gear technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as poor corrosion resistance, poor reliability, damage, etc., to achieve good corrosion resistance, improve service life, and reliability. The effect of improving the stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

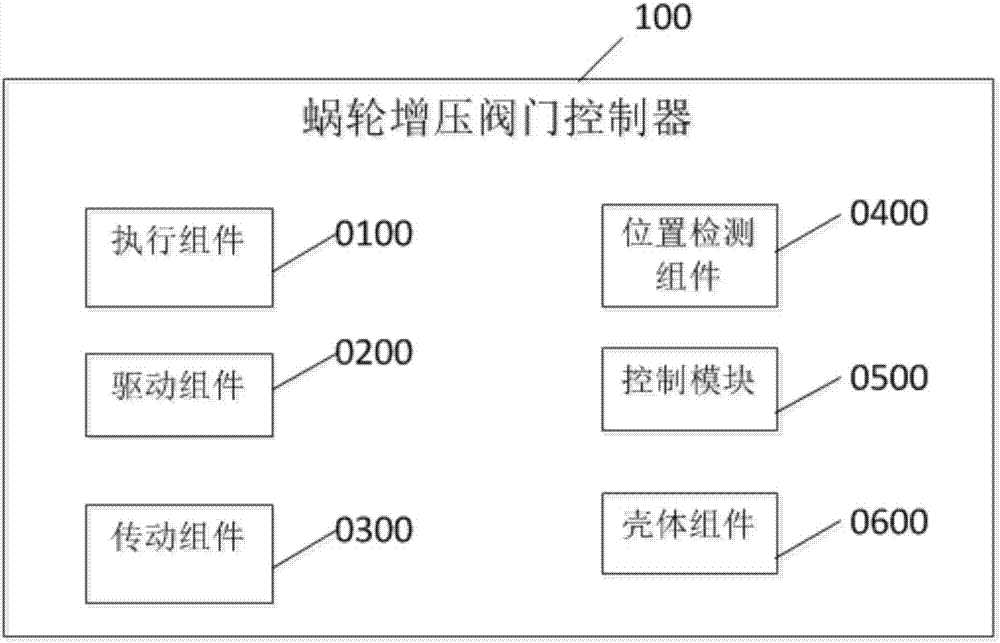

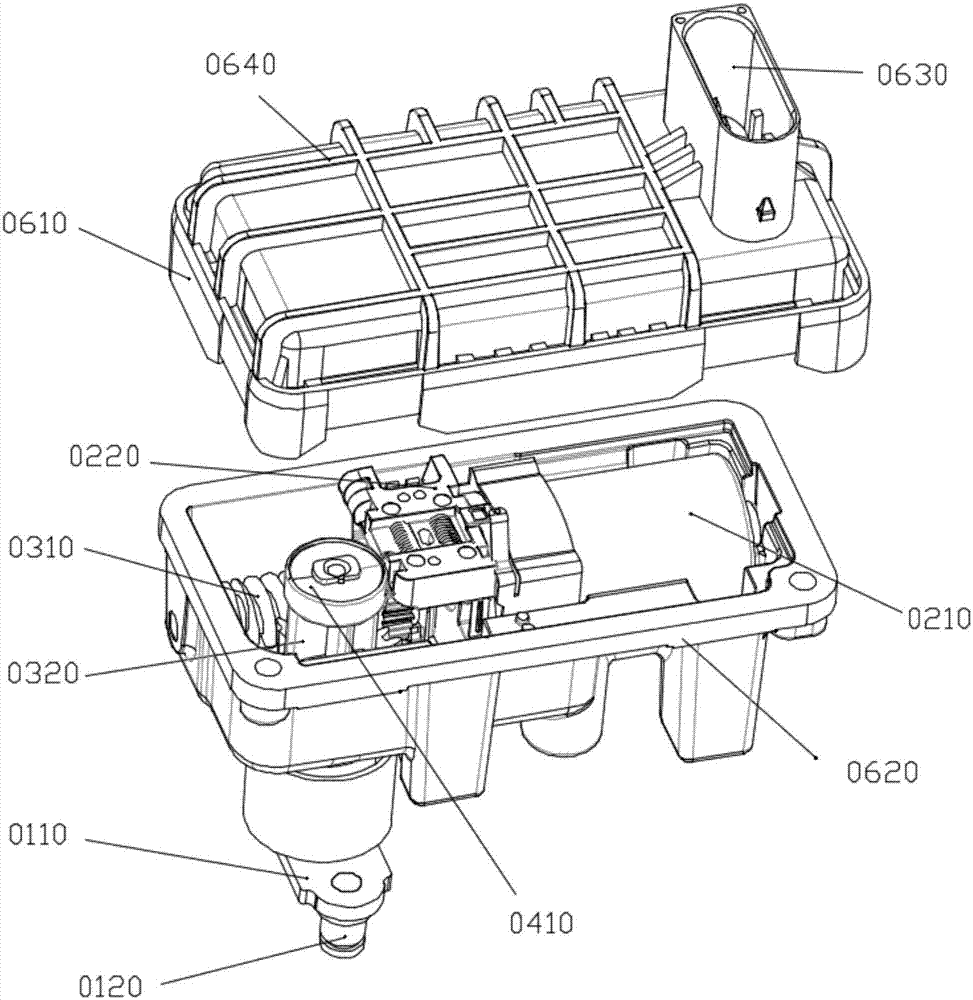

[0067] Such as Figure 1-Figure 4 As shown, this example provides a turbocharging valve controller 100 for precisely controlling the opening of the turbocharging valve.

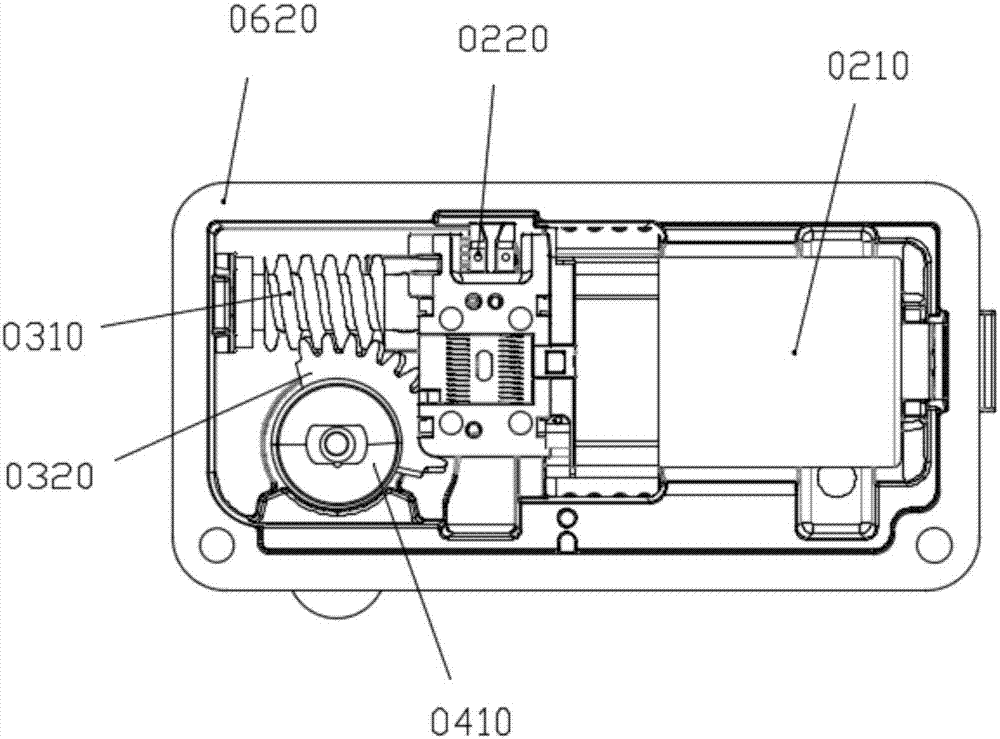

[0068] In this embodiment, the turbocharger valve controller 100 includes an execution assembly 0100 , a drive assembly 0200 , a transmission assembly 0300 , a position detection assembly 0400 , a control module 0500 , and a housing assembly 0600 .

[0069] Specifically, the driving assembly 0200 is used to provide initial power to drive the actuator assembly 0100 to move. As a preferred driving assembly 0200, the driving assembly 0200 in this embodiment includes a motor 0210, such as a common motor, a stepping motor or a servo motor. The motor 0210 is arranged in the housing assembly 0600 , and the housing assembly 0600 is also provided with components such as a circuit, a motor pin plug 0220 , and a motor pin socket 0230 for supplying power to the motor 0210 . Further, the drive assembly 0200 in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com