High-precision temperature control device based on particle accelerator material irradiation and temperature control method thereof

A particle accelerator and temperature control device technology, applied in the field of material ion irradiation research and application, can solve problems such as difficulty in applying temperature control, and achieve the effects of reducing temperature overshoot effect, reducing temperature fluctuation, and improving temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

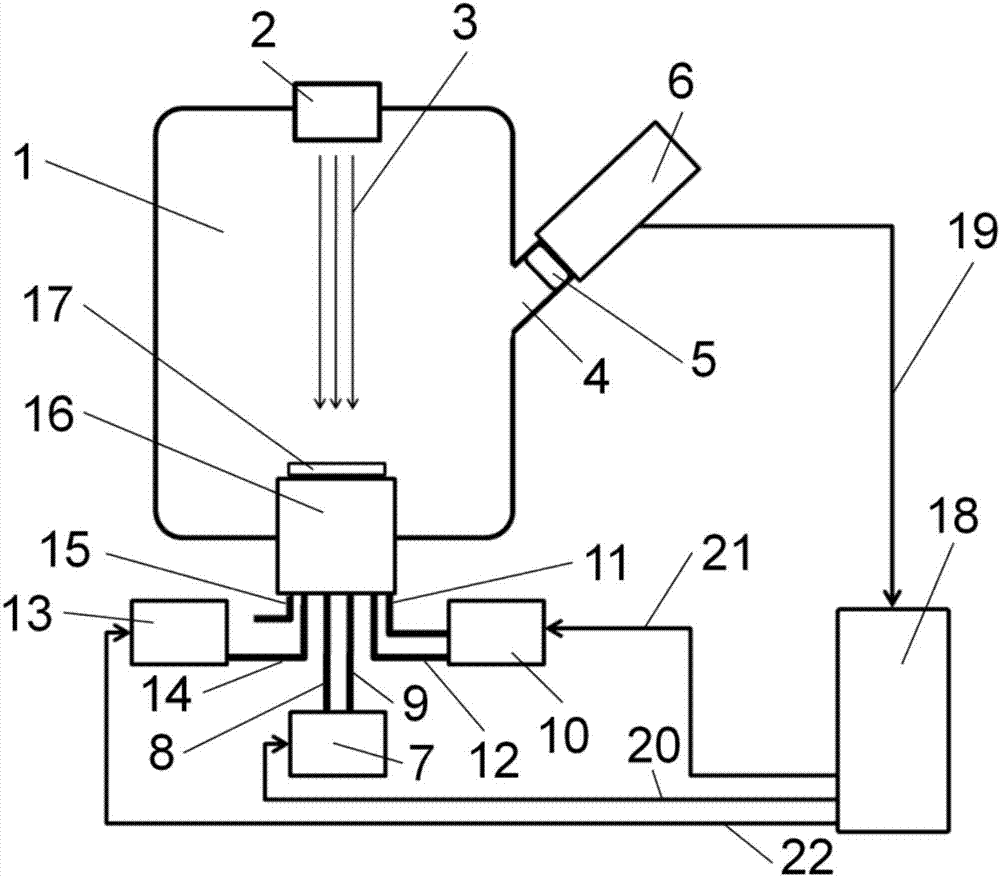

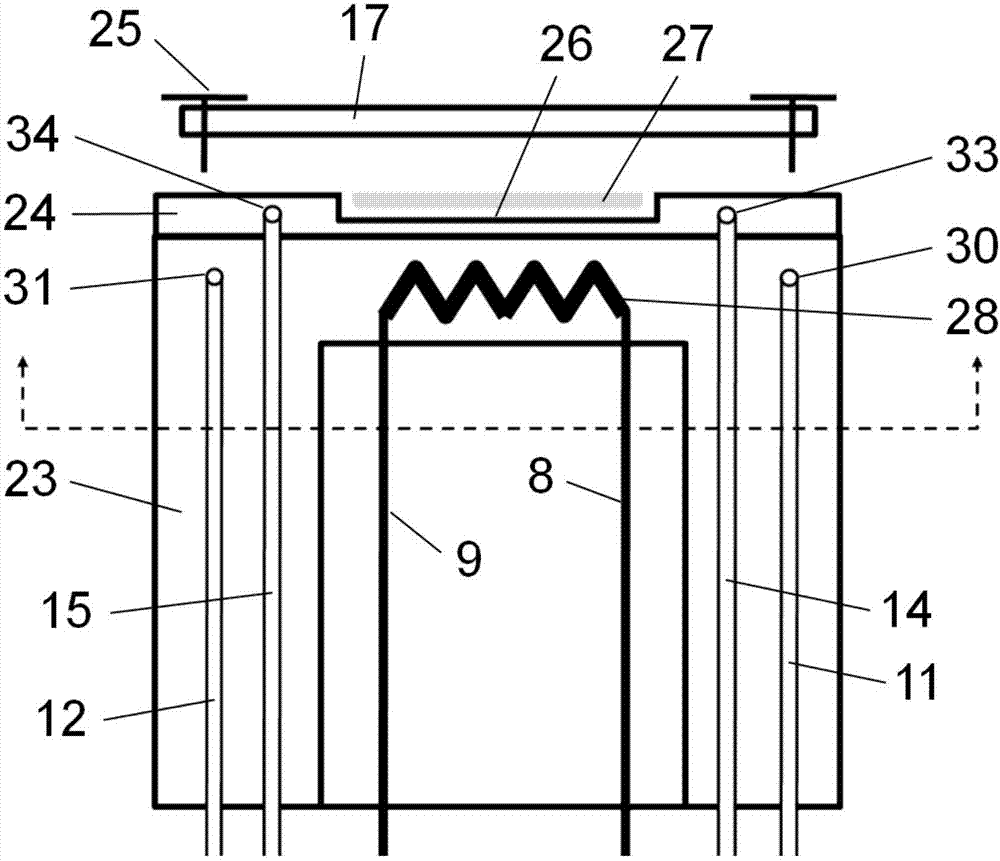

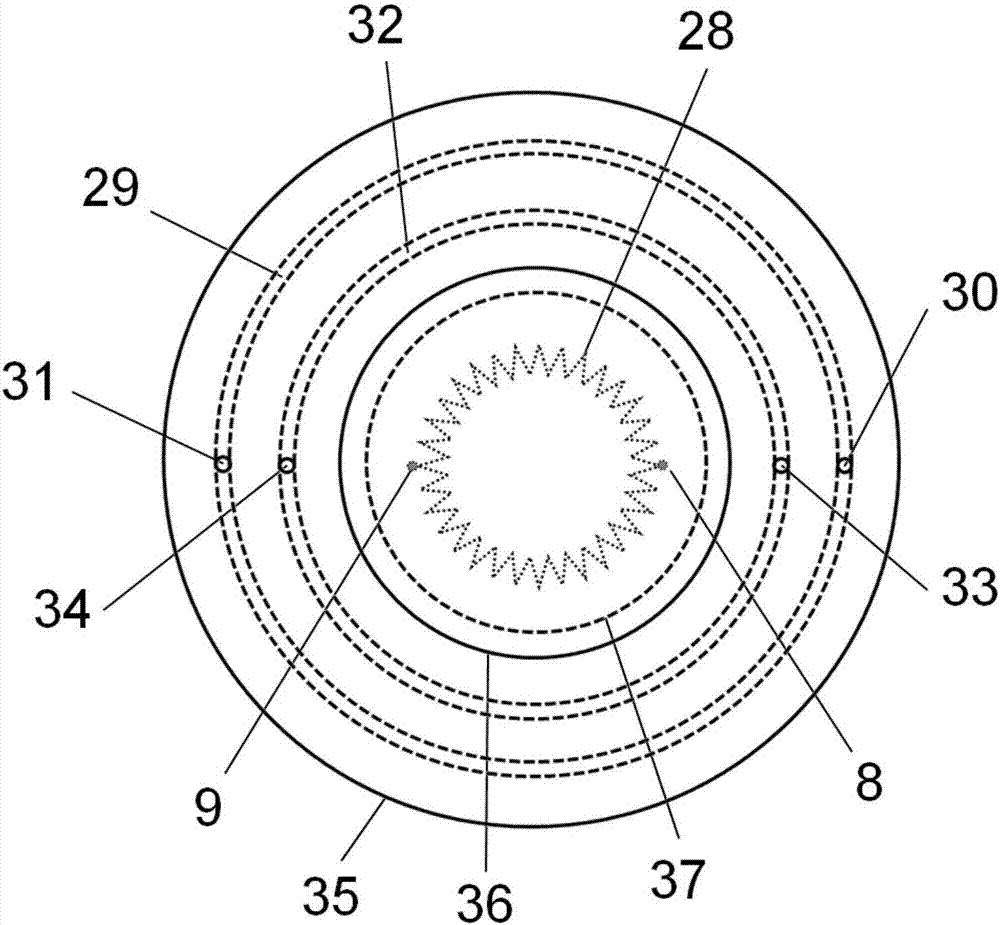

[0054] The high-precision temperature control method based on the irradiation of particle accelerator materials described in this embodiment is realized by using the above-mentioned temperature control device, and its operation steps are carried out according to the above-mentioned steps.

[0055] In this embodiment, the particle accelerator used is a 2×3MV commercial linear tandem particle accelerator, and an infrared temperature measurement channel 4 is arranged in the vacuum chamber 1 at the end of the ion irradiation beam;

[0056] The infrared thermal imager 6 used is provided by FLIR company, the product model is A655sc, and its temperature measurement range is from room temperature to 1000°C; after calibration, the temperature measurement accuracy of the infrared temperature measurement unit for the irradiation temperature of the material sample is ≤1-5°C;

[0057] The infrared glass window 5 used adopts infrared germanium glass with high light transmittance;

[0058]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com