Integrated tension cable-diaphragm structure of back cable open type and construction method thereof

A technology of overall tensioning and construction methods, applied in the direction of building structure, construction, etc., can solve the problem that the structural form does not meet the requirements of the design structural form, the overall rigidity of the surrounding steel structure is high, and the controllability of the construction stress state is poor. problem, to achieve the effect of beautiful appearance, lower difficulty and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] A kind of embodiment of the open-type integral tension cable-membrane structure that has back cable of the present invention is as follows:

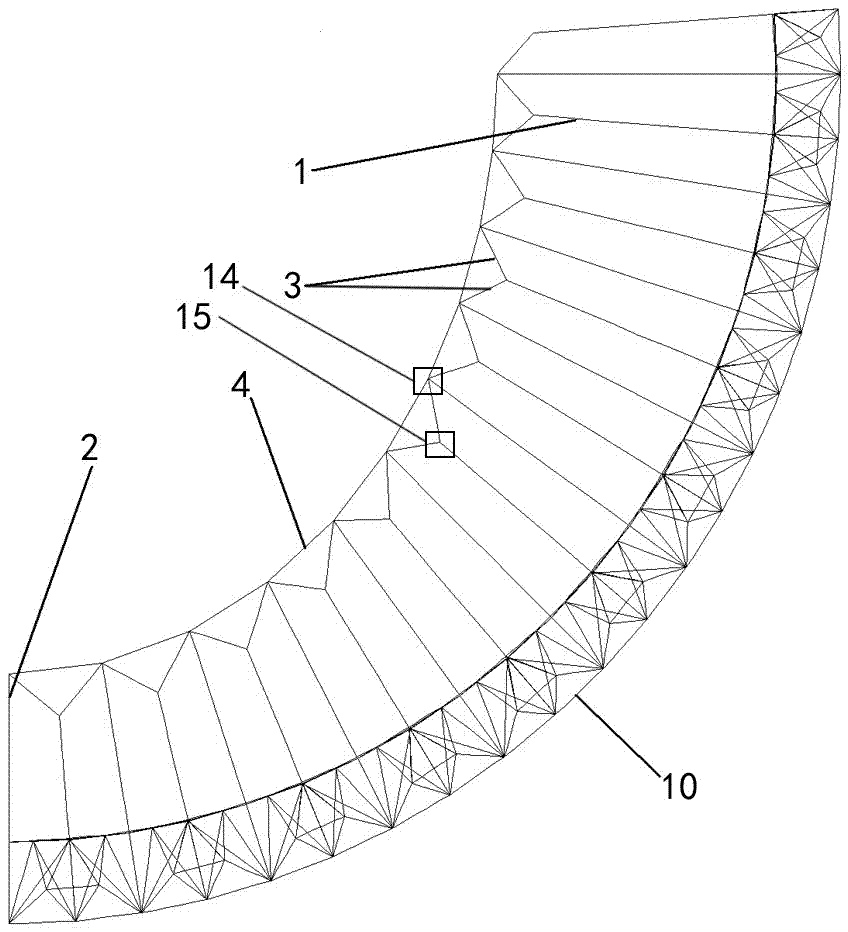

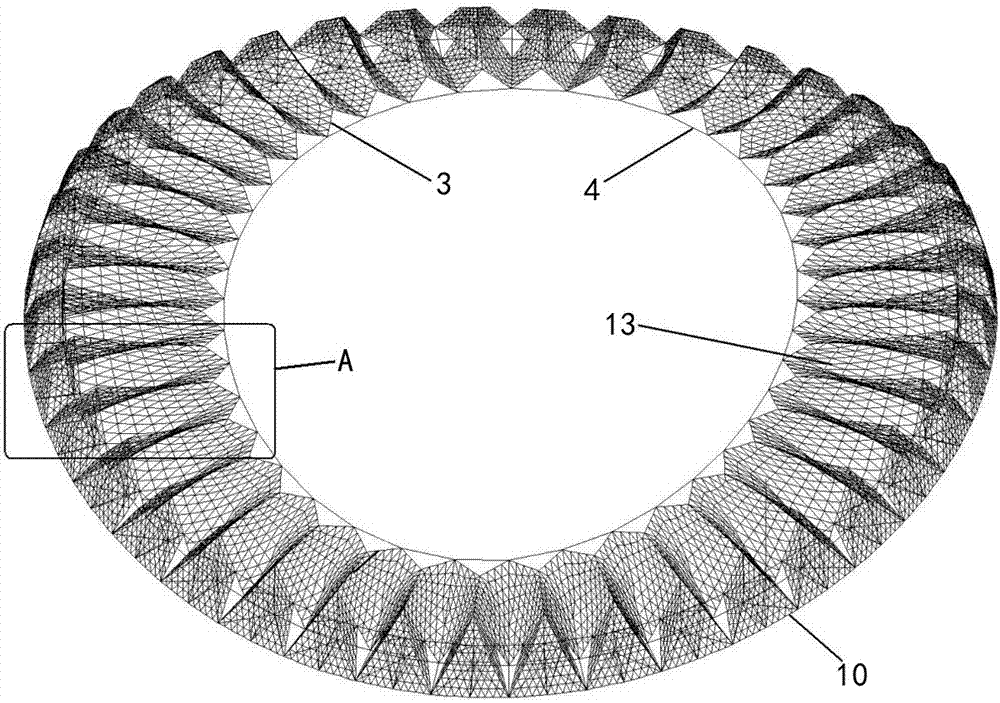

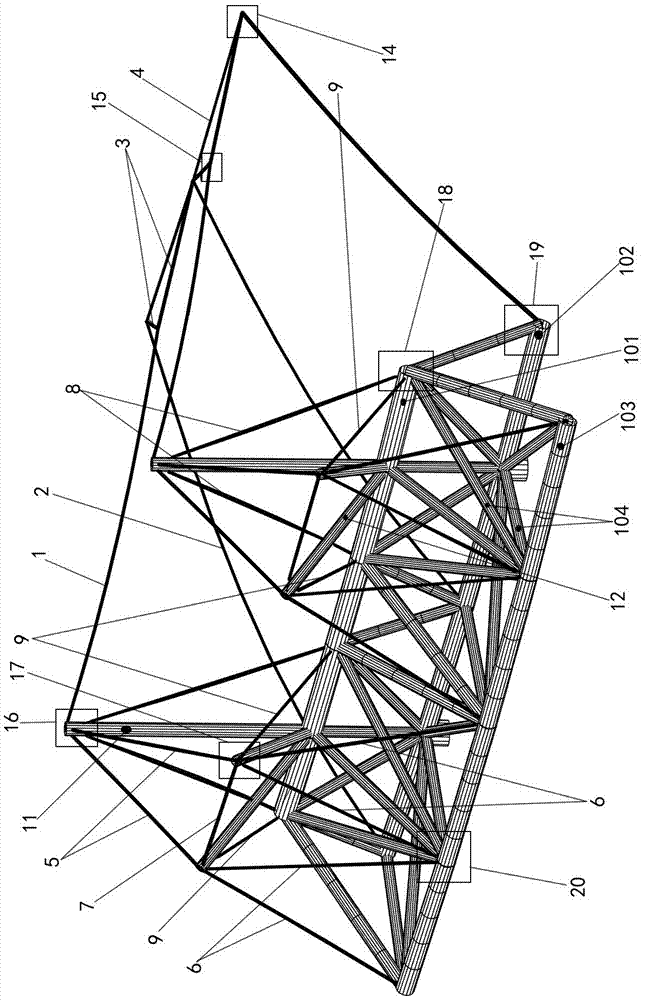

[0065] see Figure 1-3 As mentioned above, it includes the peripheral steel structure, the internal cable system connected with the peripheral steel structure and the coating 13, and also includes the external back cable system connected with the peripheral steel structure, and the various components are connected through nodes.

[0066] The internal cable system includes a notochord 1, a valley cord 2, an inner notochord 3 and an inner ring cord 4, and the adjacent notochord 1 and the valley cord 2 serve as the skeleton of the coating 13, passing between the adjacent notochord 1 and the valley cord 2 The tensioned coating 13 forms a tensioned cable-membrane structure.

[0067] The peripheral steel structure includes a ring truss 10 at the bottom, a diagonal brace 12 connected to the top of the ring truss 10 with the head facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com