Full-automatic smart seam-beautifying machine

A beautiful sewing machine, fully automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of instability and poor efficiency, and achieve the effect of fast work efficiency, strong practicability and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

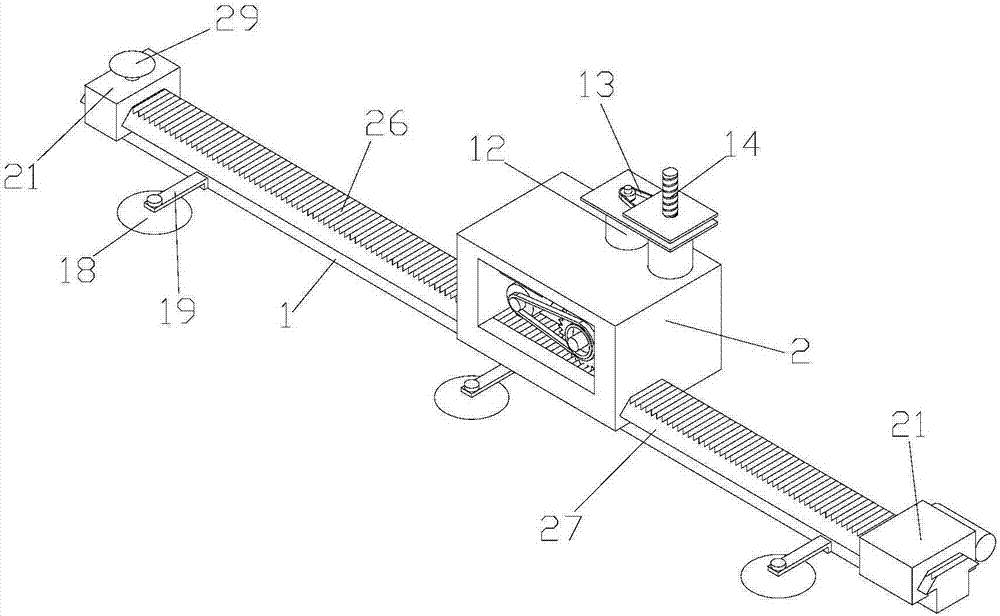

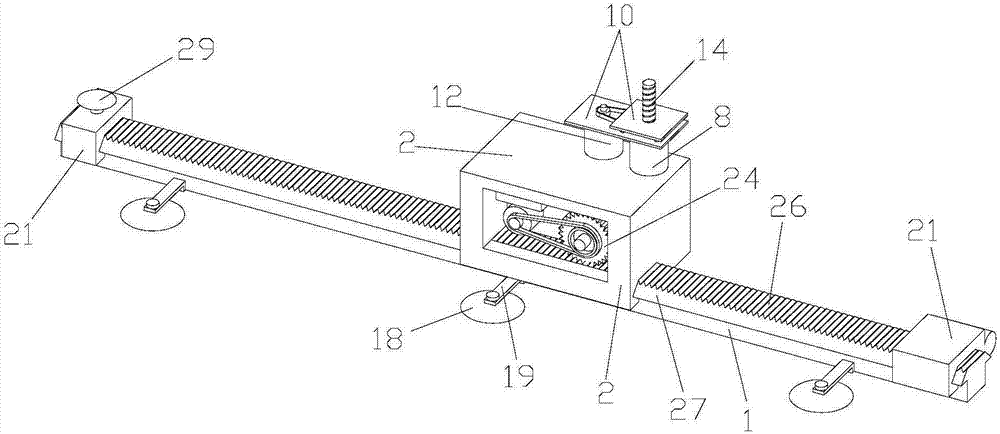

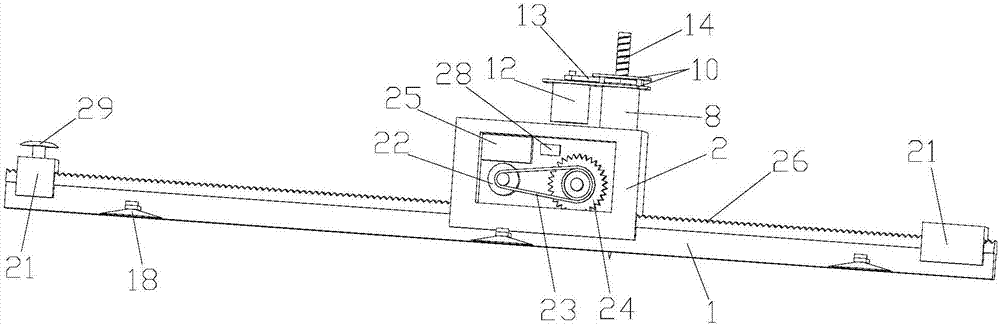

[0036]In this embodiment, a fully automatic intelligent tile beautifying machine includes a linear track 1 on which a translation frame 2 is slidably installed, and a seam wall grinding system and a gap dust removal system are installed on the above-mentioned translation frame 2 and injection system. The above-mentioned seam wall grinding system can polish the seam wall of the tile seam, so as to make the seam wall of the tile seam more smooth, and can remove excess adhesive in the tile seam; the above seam dust removal system can absorb the above seam wall grinding system. Dust and dregs are generated, and the surface of the wall of the tile gap is cleaner; the above-mentioned injection system can inject the tile beautifying agent into the wall where the dust and dregs have been removed by the gap dust removal system, and automatically complete the beautification of the tile gap.

[0037] After the above-mentioned translation frame 2 is slidably installed on the above-mention...

Embodiment 2

[0042] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the above-mentioned gap grinding system includes a high-speed motor 3 and a grinding sheet 4, and the above-mentioned high-speed motor 3 is detachably and fixedly installed on the side wall of the above-mentioned translation frame 2 Above, the above-mentioned polishing sheet 4 is synchronously mounted on the rotating shaft of the above-mentioned high-speed motor 3 , and at this time, the above-mentioned high-speed motor 3 can drive the above-mentioned polishing sheet 4 to rotate. The grinding sheet 4 is limited to be installed vertically on the above-mentioned translation frame 2. Specifically, a grinding wheel can be selected as the above-mentioned grinding sheet 4, and its lowest point is lower than the bottom wall of the above-mentioned translation frame 2. When it is correctly positioned and driven to move at a high speed After rotating, the grinding sheet 4 can polish the slit wall ...

Embodiment 3

[0045] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the above-mentioned gap dust removal system is limited to include a dust collection bin 5, a suction nozzle 6 and a dust suction fan 30 (not shown in the figure), and the above-mentioned dust collection bin 5 is also installed on the side wall of the above-mentioned translation frame 2 (on the same side as the above-mentioned high-speed motor 3), and a dust channel 7 is connected to the entrance of the above-mentioned dust collection bin 5, and a suction nozzle is installed at the other end of the dust channel 7 6. A dust suction fan 30 is cooperatingly installed inside the above-mentioned dust channel 7 , and the above-mentioned suction nozzle 6 is limited to be arranged at a position close to the polishing sheet 4 . At this time, when the above-mentioned dust suction fan 30 is working, it will generate a suction force in the above-mentioned dust passage 7 and the suction nozzle 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com