Gas exhaust tube of insulated lorry

A technology for automobile exhaust and exhaust pipes, applied in exhaust devices, noise reduction devices, sound absorption, etc., can solve the problems of complex processing technology, easy scratch damage, muddy water, oil pollution, etc., and achieve simple packaging processing technology and popularization Improved usability and high mass production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

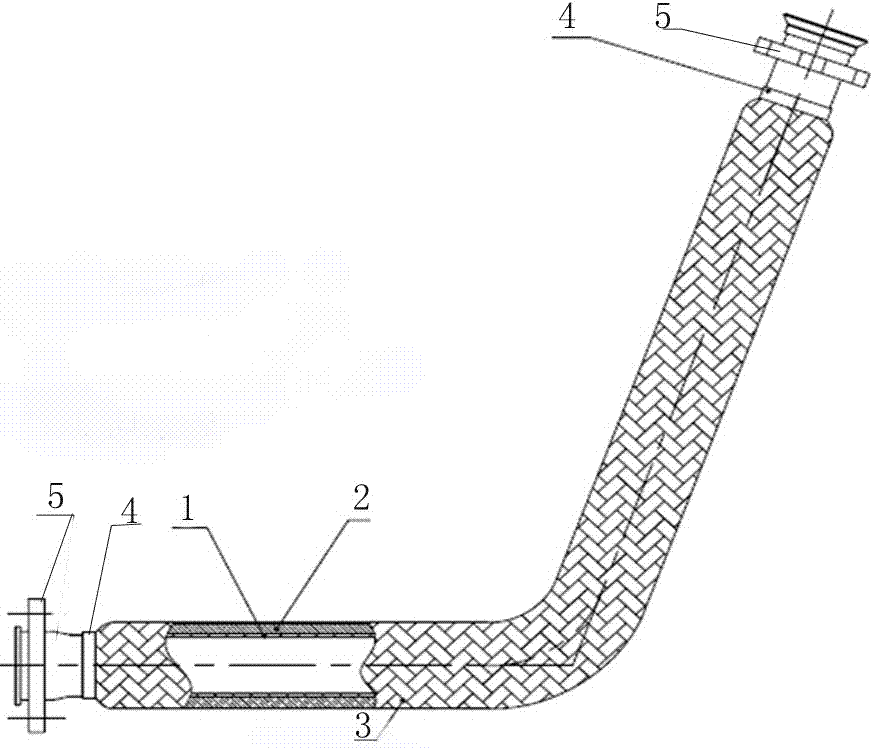

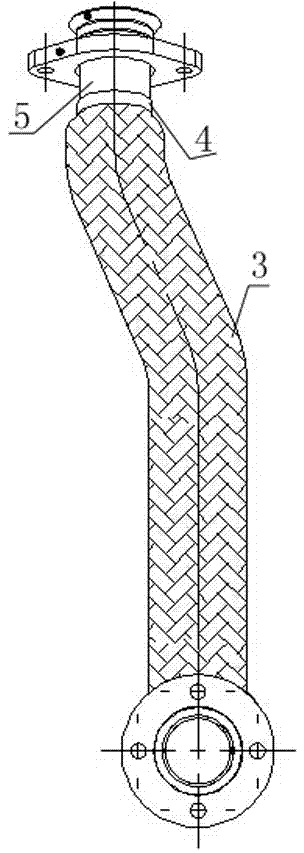

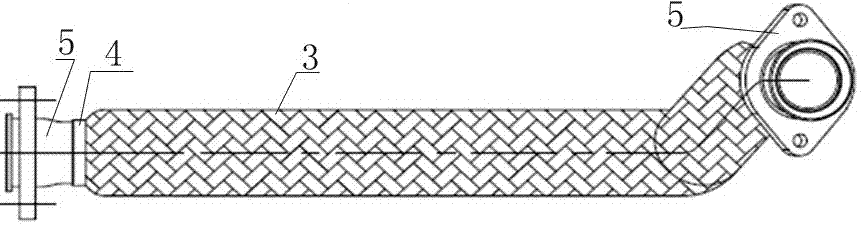

[0019] The present invention as figure 1 As shown in / 2 / 3,

[0020] An insulated automobile exhaust pipe, comprising an exhaust pipe 1 to be wrapped, relying on the exhaust pipe 1 to be wrapped, the exhaust pipe 1 is wrapped with a layer of thermal insulation cotton pad 2, and the outer surface of the thermal insulation cotton pad 2 is wrapped with a layer Wire braided netting, wherein the length of the metal wire braided netting is longer than the length of the thermal insulation cotton pad 2, and is fixed with a snap ring hoop 4 at the flange 5 places at the two ends of the exhaust pipe 1.

[0021] The insulation cotton pad 2 is wound around the outside of the exhaust pipe 1 in a circular structure, starting from one end of the exhaust pipe 1 and gradually winding to the other end of the exhaust pipe 1 in sequence.

[0022] The thermal insulation cotton pad 2 has the characteristic of high temperature resistance.

[0023] The metal wire braided net is a stainless steel bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com